A pre-twisted tension clamp with monitoring function

A tension clamp and pre-twisted technology, applied in the field of overhead line fittings, can solve the problem of no tension and temperature monitoring, and achieve the effects of avoiding cross-sensitivity effects, small structural changes, and strong operability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

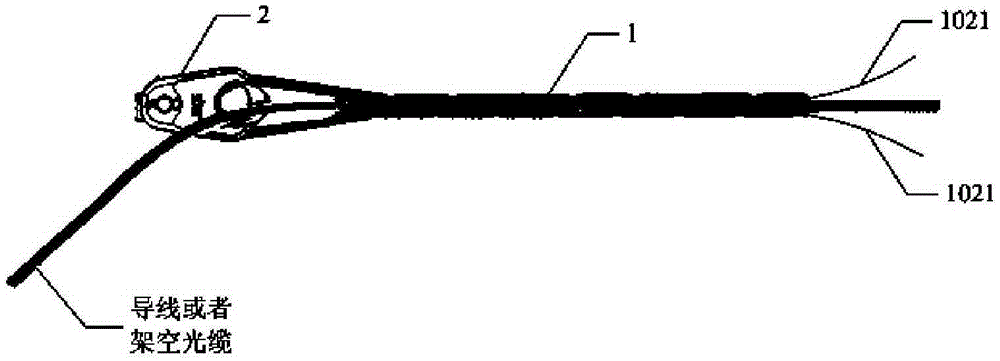

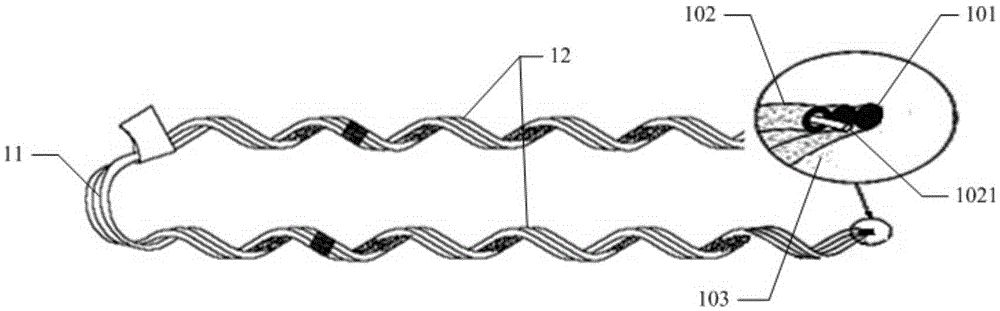

[0020] The following is attached figure 1 and 2 , the present invention will be described in further detail.

[0021] A pre-twisted tension clamp with monitoring function, comprising a tension pre-twisted wire 1 and a matching connecting fitting 2, the tension pre-twisted wire 1 consists of two helical metal wires 101 and a built-in monitoring The helical metal tubes 102 of the optical fiber 1021 are bonded side by side, and the tension-resistant pre-twisted wire 1 composed of two helical metal wires 101 and the helical metal tube 102 with the built-in monitoring optical fiber 1021 is folded in half to make a U-shaped bend The head 11 and the U-shaped elbow 11 are set on the connecting ring of the connecting fitting 2 so that the tension clamp is connected with the pole tower, and the remaining parts (legs) 12 of the tension pre-twisted wire 1 are evenly arranged to form an empty pipe.

[0022] The inner diameter of the empty tube formed by the legs 11 of the tension pre-str...

Embodiment 2

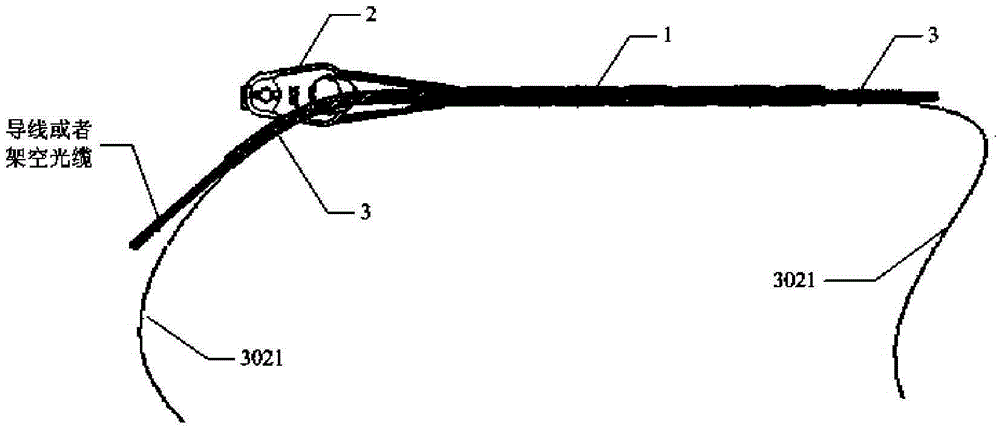

[0027] The following is attached image 3 and 4 , the present invention will be described in further detail.

[0028] The difference from Example 1 is that a pre-twisted tension clamp with monitoring function includes tension pre-twisted wire 1 and matching connecting hardware 2, and also includes inner layer pre-twisted wire 3, inner layer pre-twisted wire 3 There are several sub-bundles 301. In this embodiment, the inner pre-twisted wire 3 has 4 sub-bundles, respectively 31, 32, 33 and 34, wherein the sub-bundles 31, 32 and 33 are composed of 4 helical metal wires 301 It is bonded and fixed side by side, and the sub-bundle 34 is formed by bonding and fixing three helical metal wires 301 and one helical metal tube 302 with a built-in monitoring optical fiber 3021 side by side. In order to increase the frictional force, corundum is bonded inside the helical metal wire 301 and the helical metal tube 302 . The inner layer pre-twisted wire 3 including the above four sub-bundle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com