Magnetic steel disk structure for wind power generation system under extreme conditions

A technology of wind power generation system and magnetic steel disk, which is applied to magnetic circuits, electrical components, electromechanical devices, etc., can solve the problem of unreasonable thickness design of magnetic steel disk and magnetic steel, affecting power generation efficiency and power generation, and failure of wind turbine work. and other problems to achieve the effect of eliminating the cantilever effect, improving the utilization rate of magnetic energy, and improving the power generation and power generation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

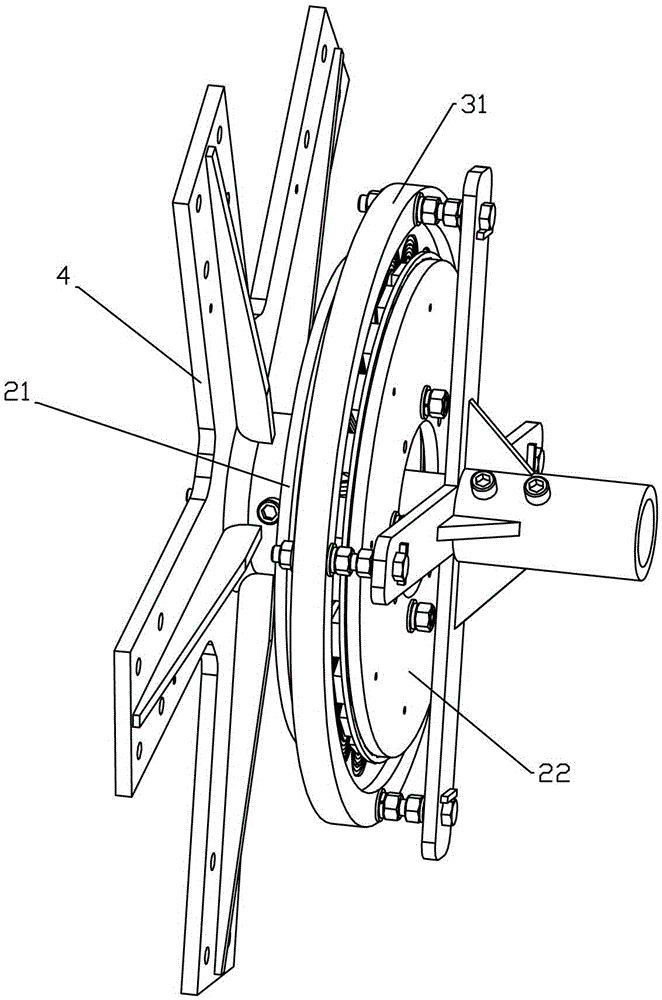

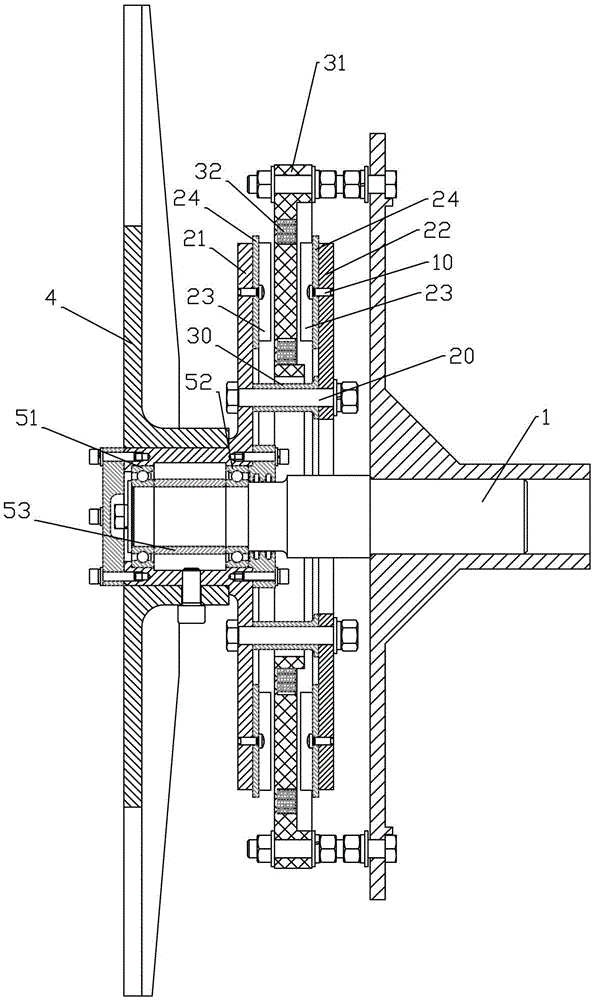

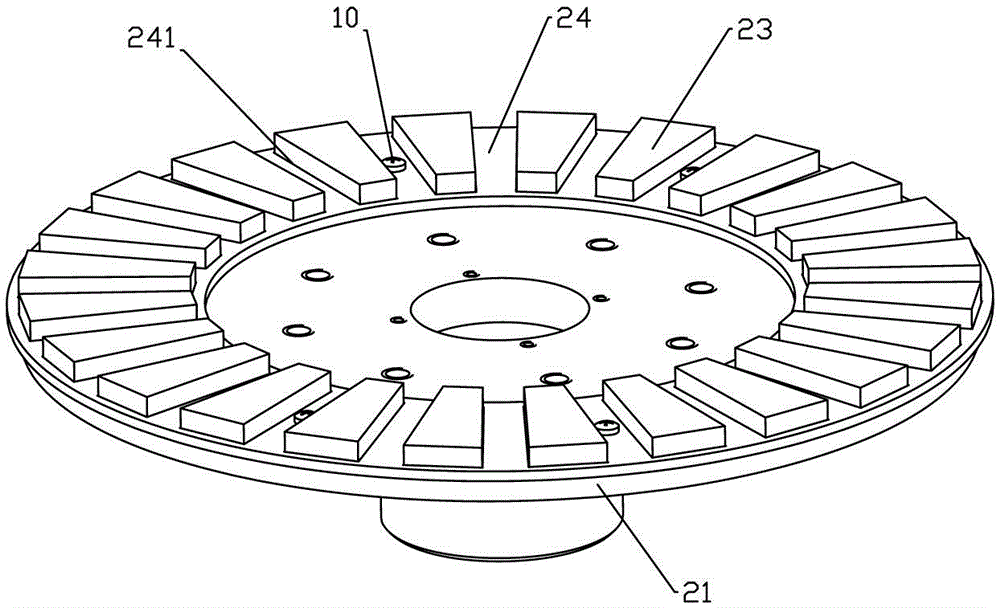

[0023] Reference Figure 1 to Figure 10 , The magnetic steel disc structure for wind power generation system under extreme conditions of the present invention includes the main and driven magnetic steel discs 21, 22 which are coaxial with the generator main shaft 1 and can rotate relative to it, the main and driven magnetic steel discs 21, There are several pairs of magnetic steels 23 with opposite polarities on the opposite disk surface 22. The thickness ratios of the magnetic steel 23 and the main and driven magnetic steel disks 21 and 22 are both 1.25 to 1.67. The above-mentioned thickness ratio makes the magnetic field lines concentrated on Between the main and driven magnetic steel plates 21, 22, the phenomenon of magnetic leakage is prevented, and the magnetic energy utilization rate of the magnetic steel 23 is greatly improved. In this embodiment, the thickness of the magnetic steel 23 is 10 mm. The thickness of the driven magnetic steel plates 21, 22 are equal and 6mm o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com