Thermal transfer device with reduced vertical profile

A technology of heat transfer fluid and condenser, which is applied in the field of heat transfer devices with reduced vertical section

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

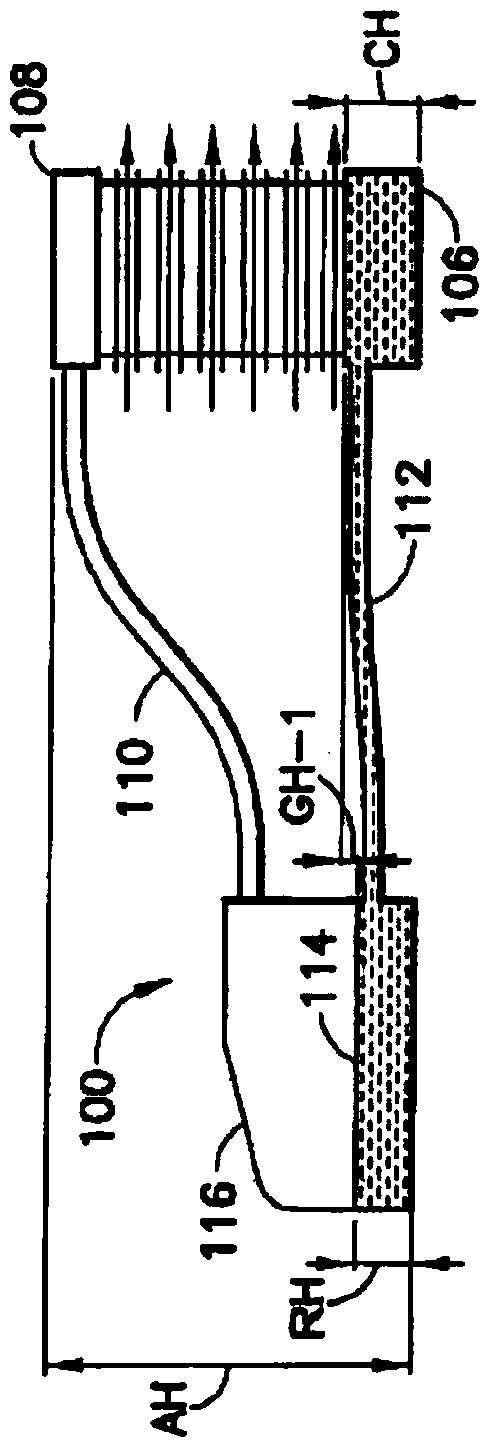

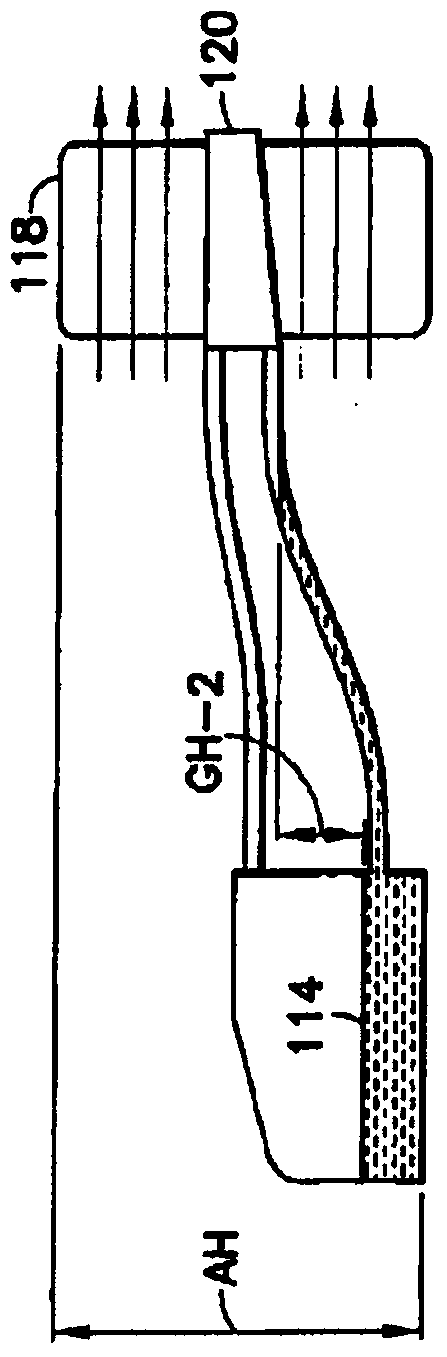

[0034] According to a preferred embodiment of the invention, a heat transfer device or "closed loop fluid cooling system" according to the invention is shown generally at 10 in FIG. 4 . The heat transfer device 10 includes a reservoir 12, which acts as an evaporator, for holding a heat transfer fluid 14, and a first conduit 16, for directing the heat transfer fluid 14 out of the reservoir when the heat transfer fluid is in a vapor state. 12; and a second conduit 18 for directing the heat transfer fluid 14 back to the reservoir 12 once it has been condensed from its vapor state to its liquid state. The maximum height to which the liquid portion of the heat transfer fluid can rise before flooding the condensing surface is designated h in FIG. 4 .

[0035] In a preferred embodiment, heat transfer fluid 14 is water or deionized water. When the design places specific requirements on the cooling fluid, for example, freeze resistance, corrosion resistance, or requires the cooling fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com