Cast-weld equipment and cast-weld method of sealed batteries

A sealed battery and casting welding technology, which is applied in the field of battery manufacturing, can solve the problems of increased moving distance, unsmooth production, and increased space, so as to reduce the space occupied by equipment, avoid waiting time, and reduce input costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

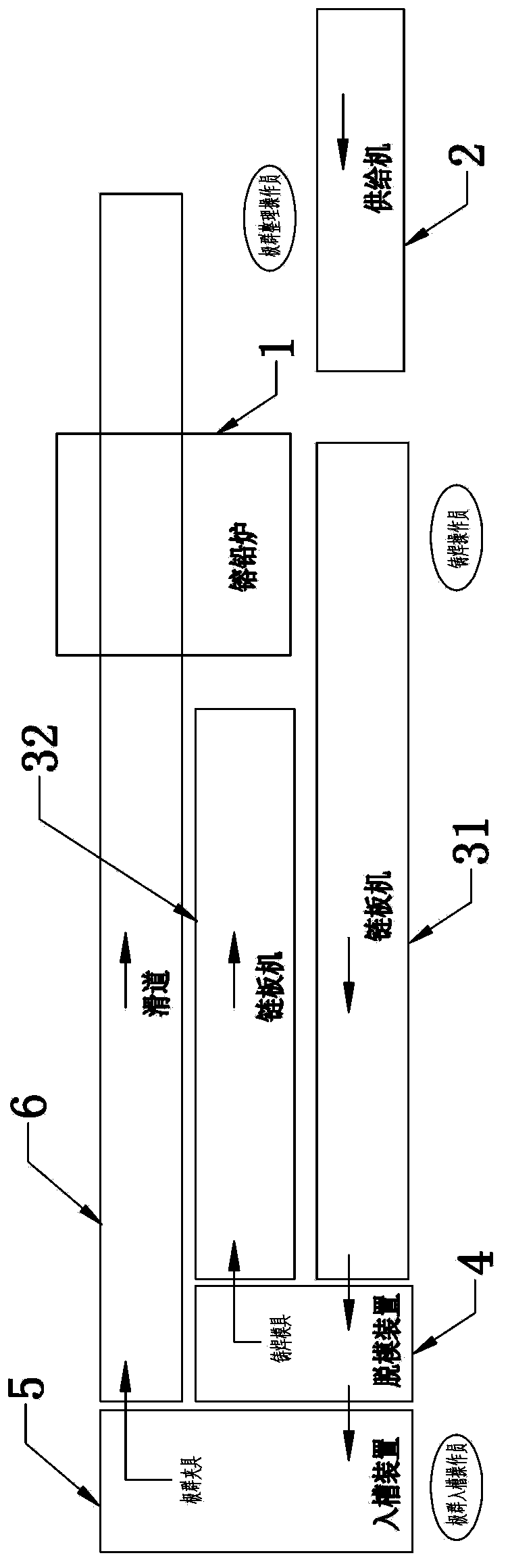

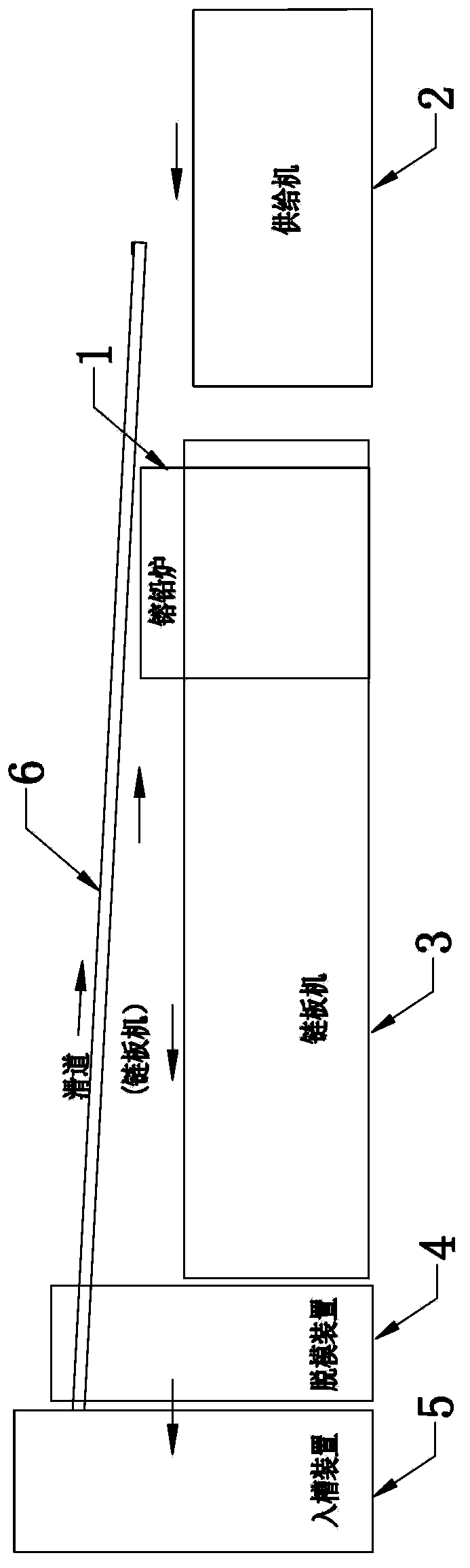

[0027] like figure 1 and figure 2 As shown, the casting and welding equipment of the sealed battery of the present invention includes a lead melting furnace 1, a supply machine 2, a chain plate machine 3, a demoulding device 4, a slotting device 5 and a slideway 6; the lead melting furnace 1 and feeder 2 are respectively located at the front end of the casting and welding equipment; the end of the chain plate machine 3 is connected to the front end of the stripping device 4; the end of the stripping device 4 is connected to the front end of the slotting device 5 Connection; the end of the slotting device 5 is connected with the slideway 6 . Wherein, the chain plate machine 3 is provided with a forwardly moving chain plate machine 31 and a reversely moving chain plate machine 32, and the forwardly moving chain plate machine 31 and the reversely moving chain plate machine 32 arranged parallel to each other. When the operator puts the heated casting and welding mold from the ...

Embodiment 2

[0042] Compared with Embodiment 1, the present embodiment only changes the temperature of the lead melting furnace in the cast welding method, and the others are exactly the same as those in the embodiment.

[0043] (1) heating up;

[0044] The operator puts the casting and welding mold into the lead melting furnace and heats it up to 500°C;

[0045] Compared with Example 1, only the heating temperature of the casting and welding mold is lowered, but it does not affect the welding with the pole group mold, and the welding effect is the same.

Embodiment 3

[0047] Compared with Embodiment 1, the present embodiment only changes the temperature of the lead melting furnace in the cast welding method, and the others are exactly the same as those in the embodiment.

[0048] (1) heating up;

[0049] The operator puts the casting and welding mold into the lead melting furnace and heats it up to 600°C;

[0050] Compared with Example 1, only the heating temperature of the casting and welding mold is raised, but it does not affect the welding with the pole group mold, and the welding effect is the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com