Preparation method for plastic raincoat cloth having fluorescent effect

A plastic and fabric technology, applied in the field of plastic products, can solve the problems of insignificant warning effect, small marking area, reduced fluorescent effect, etc., and achieve the effect of excellent fluorescent effect, reasonable process arrangement, and high bonding strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

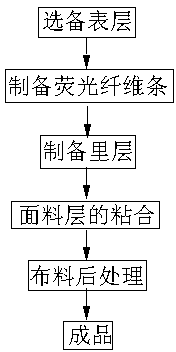

[0017] The concrete preparation process of the preparation method of the plastic raincoat cloth with fluorescent effect mentioned in the present invention is as follows:

[0018] a) Optional surface layer, the surface layer material is PVC or PU, the thickness is about 0.3mm, and the width is 1.2m;

[0019] b) Preparation of fluorescent fiber strips, the main components of fluorescent fiber strips and their percentage ratios are: fluorescent powder material 24%-26%, PET masterbatch 64%-66%, and the rest are related additives; among them, fluorescent powder The material of the material is inorganic rare earth luminous powder, and the particle size of the powder is 300-350 mesh; the particle size of the PET masterbatch is 0.3mm; the heat stabilizer in the auxiliary agent is lauric acid ester, and the active agent is ammonium bicarbonate solution , the leveling agent is selected from oxyethane, and the plasticizer is selected from DPHP;

[0020] Fluorescent fiber strips are prep...

Embodiment 2

[0025] The concrete preparation process of the preparation method of the plastic raincoat cloth with fluorescent effect mentioned in the present invention is as follows:

[0026] a) Optional surface layer, the surface layer material is PVC or PU, the thickness is about 0.35mm, and the width is 1.2m;

[0027] b) Prepare fluorescent fiber strips. The main components and percentage ratios of fluorescent fiber strips are: fluorescent powder material 26%-28%, PET masterbatch 62%-74%, and the rest are related additives; among them, phosphor powder The material of the material is inorganic rare earth luminous powder, and the particle size of the powder is 300-350 mesh; the particle size of PET masterbatch is 0.3mm; the heat stabilizer in the auxiliary agent is maleate, and the active agent is ammonium bicarbonate Propylene oxide is used as the solution and leveling agent, and DPHP is used as the plasticizer;

[0028] Fluorescent fiber strips are prepared by melt spinning process, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com