Mounting Bracket Assembly for Cross Flow Radiator Systems

A technology for installing brackets and radiators, which is applied to power plants, vehicle parts, transportation and packaging, etc., can solve the problems of increasing manufacturing costs, unfavorable parts management, and increasing types of parts, so as to increase manufacturing costs and improve lateral impact force, stress-reducing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

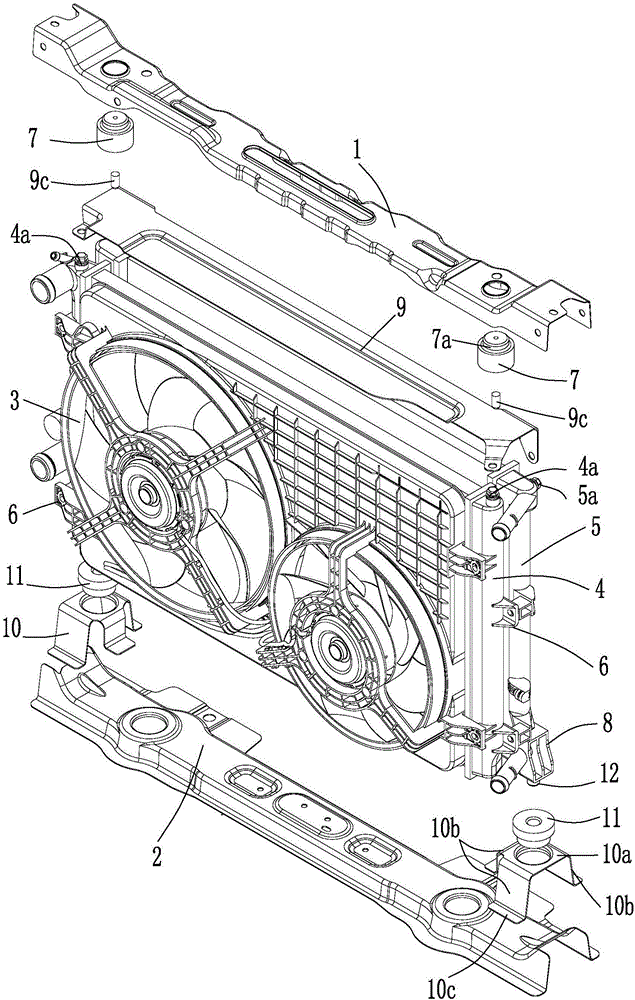

[0020] like figure 1 As shown, a mounting bracket assembly suitable for a cross-flow radiator system consists of an upper radiator mounting bracket 9 and two radiator lower mounting brackets 10, all of which are stamped and formed from metal plates, and the two radiator lower mounting brackets The mounting brackets 10 are symmetrically arranged left and right.

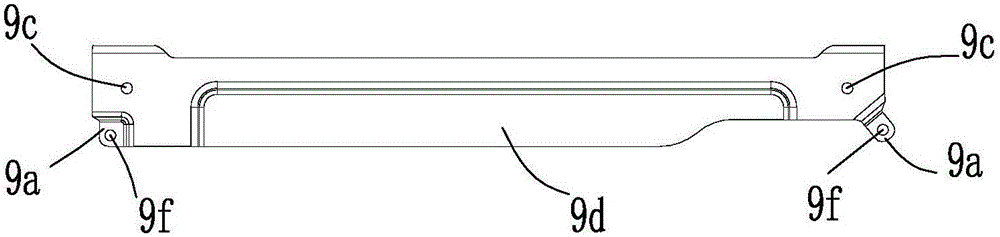

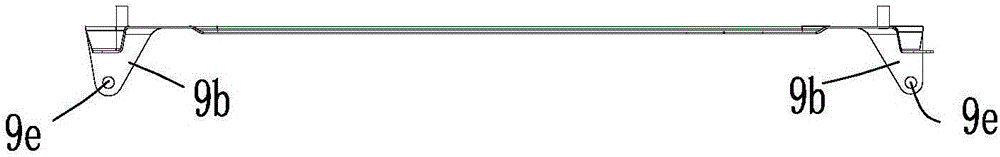

[0021] combine figure 1 —— image 3 As shown, the mounting bracket 9 on the radiator is a strip-shaped horizontal plate extending left and right, and an upper mounting positioning pin 9c extending up and down on the axis is respectively welded above the left and right ends of the mounting bracket 9 on the radiator. Rubber suspension 7 is connected. A vertically downward bending portion 9b is respectively provided at the left rear corner and the right rear corner of the mounting bracket 9 on the radiator, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com