Portable winding device

A kind of winding equipment, a portable technology, applied in the direction of conveying filamentous materials, fiber mechanical structure, thin material processing, etc., can solve the problems of affecting work efficiency and progress, large volume and weight of winding device, increasing labor intensity, etc. , to achieve high work efficiency, easy to carry, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

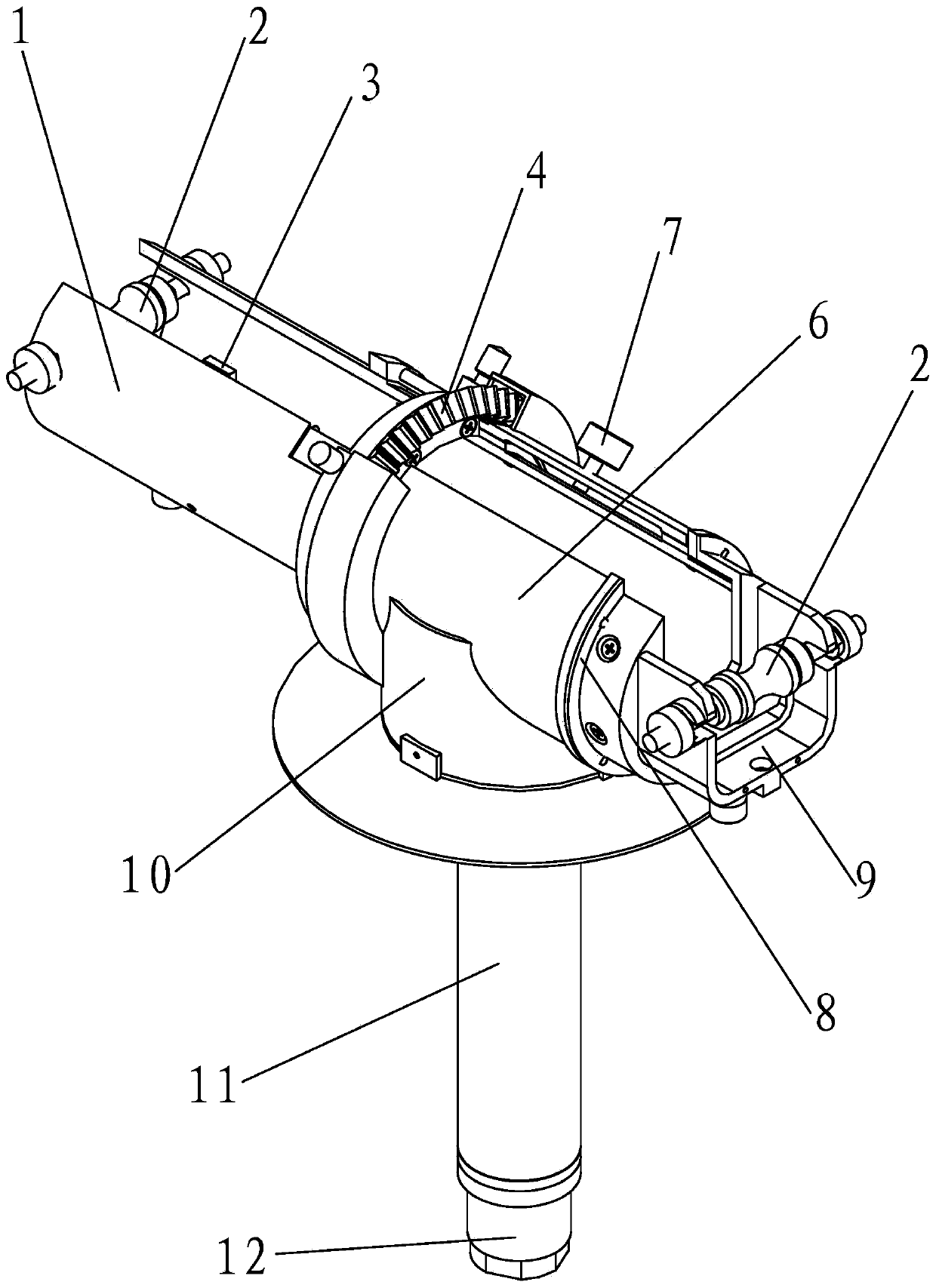

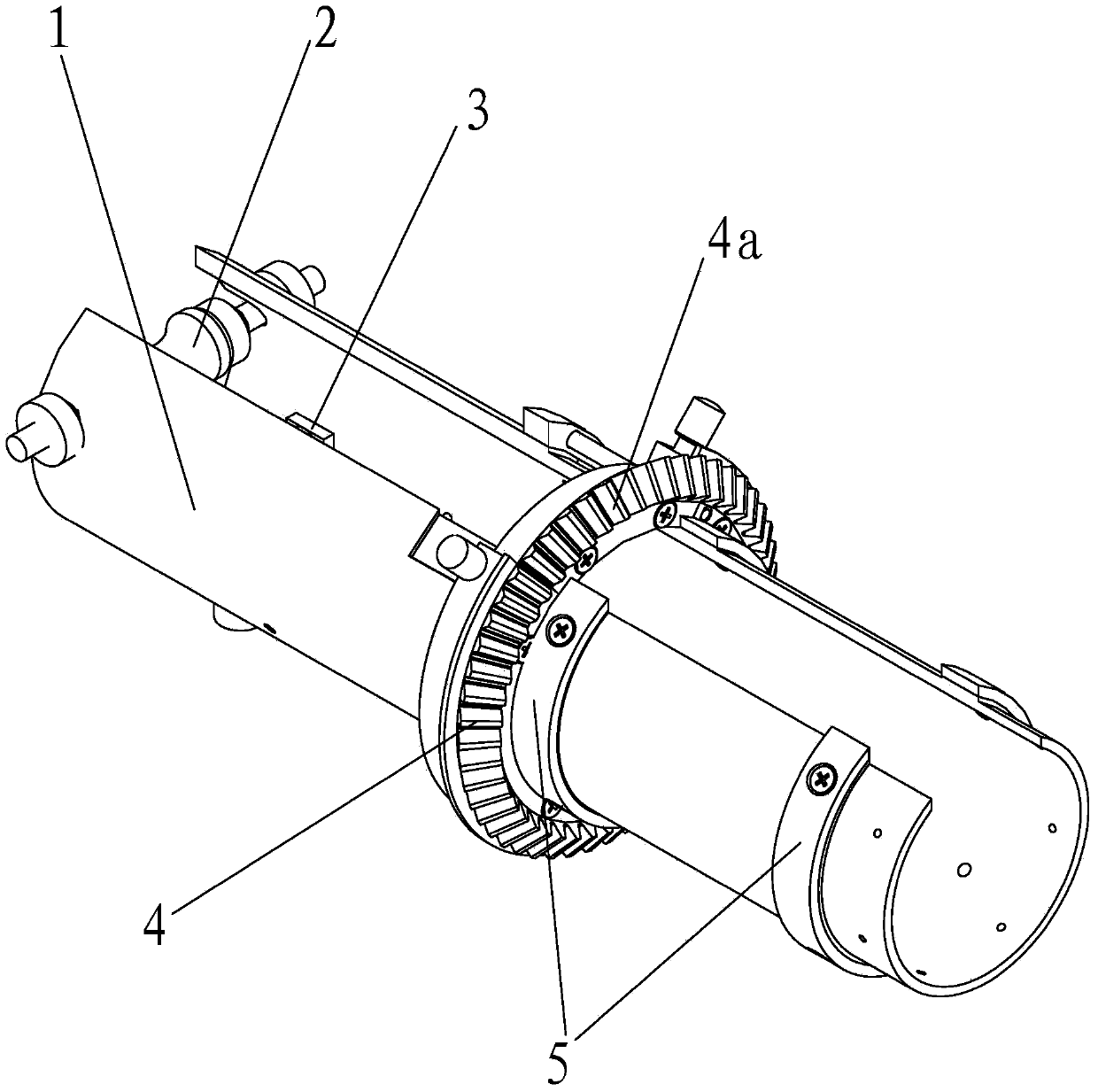

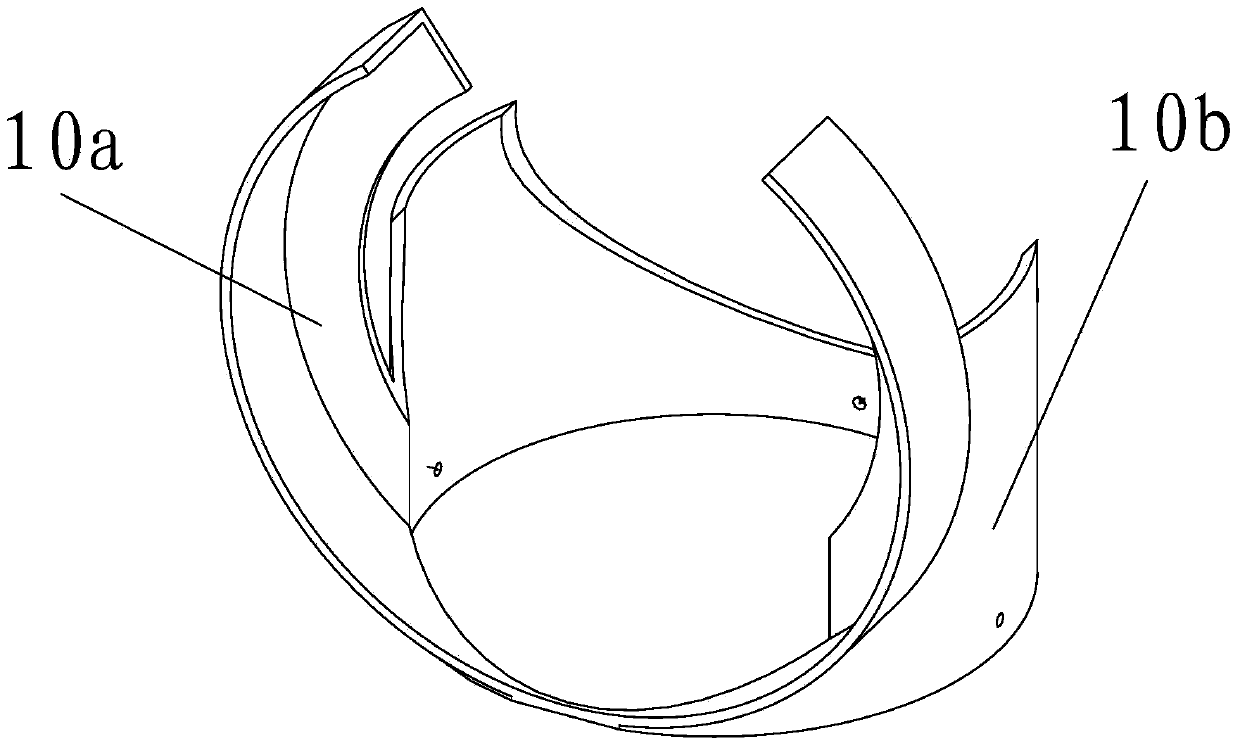

[0021] Such as figure 1 , 2 As shown in and 3, the portable winding device includes a horizontal wire routing mechanism and a vertical wire winding mechanism, wherein the horizontal wire routing mechanism is sleeved on the high-voltage wire and walks in a straight line, and the vertical wire winding mechanism rotates around the high-voltage wire to realize the winding of the optical cable.

[0022] The horizontal wire routing mechanism has an inner cylinder 1, and a wire inlet gap 1 is opened on the cylinder wall of the inner cylinder 1 along the axial direction. A crimping assembly is arranged in the inner cylinder 1, and the crimping assembly includes a lower roller 3 and an upper roller 2, and there is a creasing gap b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com