Guide rod of submersible water impeller

A technology of submersible flow propeller and guide rod, applied in the field of frame, sliding sleeve, and submersible flow propeller guide rod, can solve the problems of large economic loss and long production shutdown, reduce labor intensity, increase contact area and The effect of bearing area and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

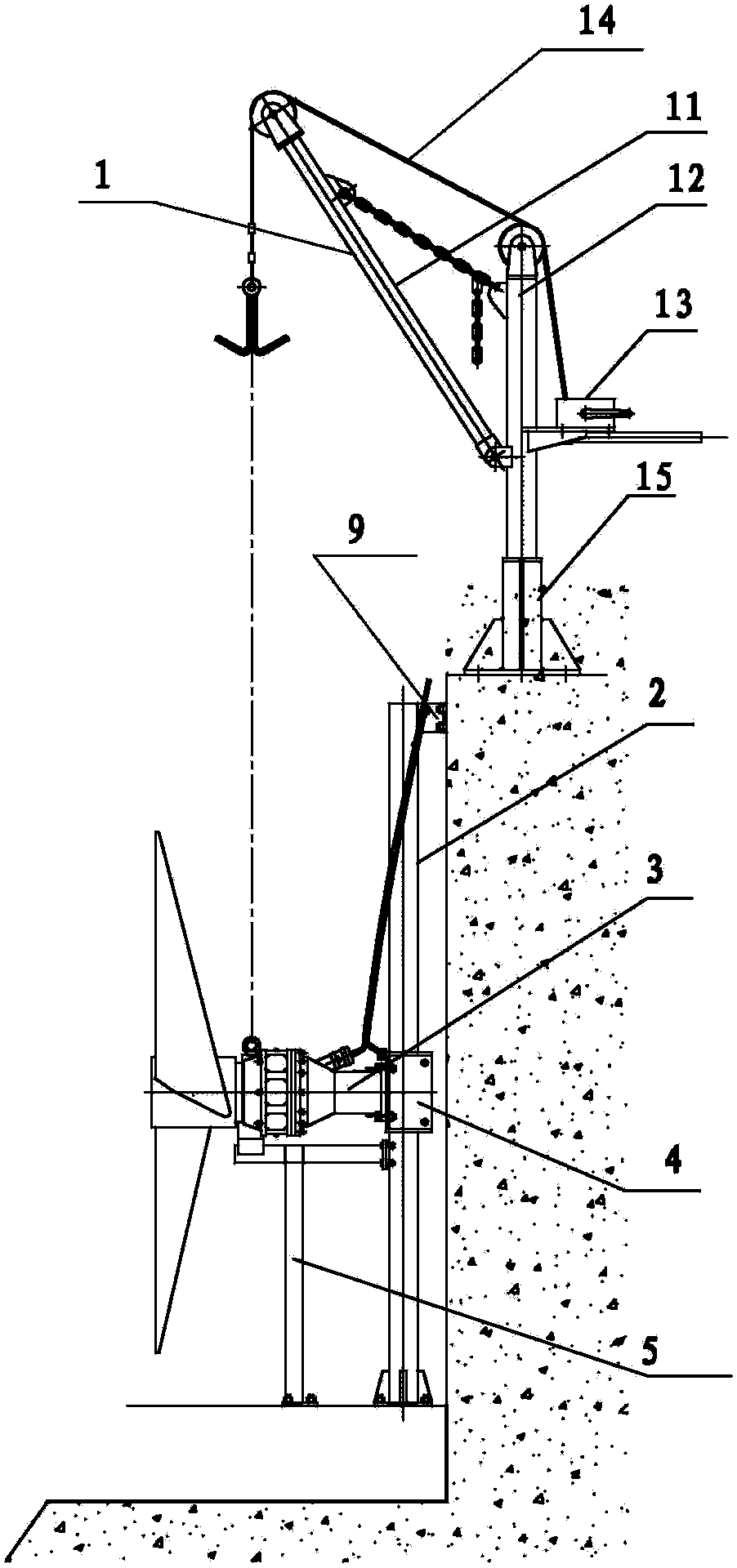

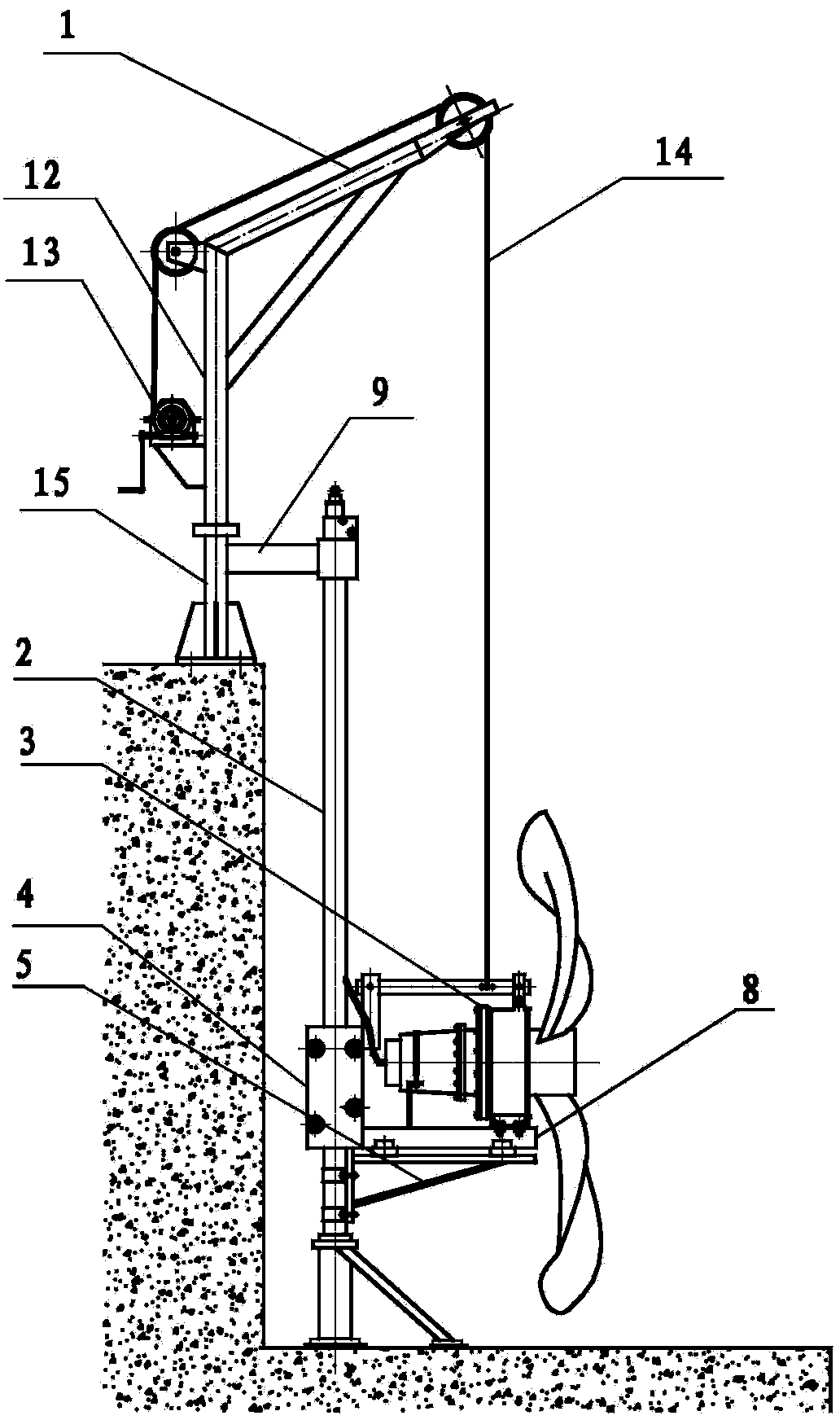

[0028] The guide rod of the submersible flow propeller of the present invention will be further described below in conjunction with the accompanying drawings.

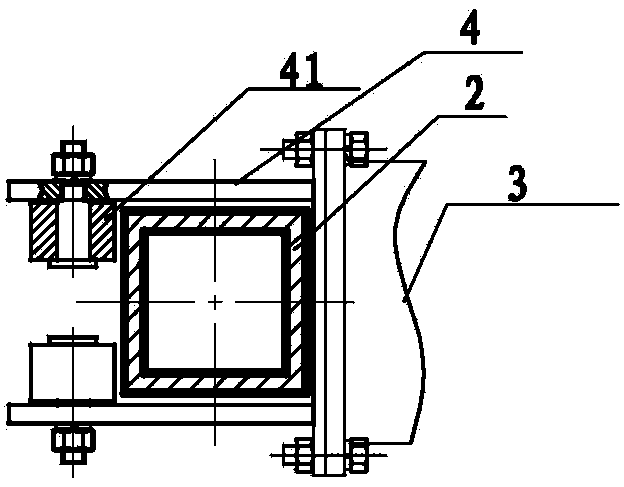

[0029] see Figure 4 , Figure 5 , apply the submersible flow propeller guide rod of the present invention on the hoist of the prior art, its U-shaped fixing frame 6 is arranged on the top of the pool, and the double-track cylindrical guide rod 2 is two parallel to each other and perpendicular to the bottom surface of the pool at the same time. Cylindrical structure. The upper end of the cylindrical guide rod 2 is fixedly installed on the U-shaped fixing frame 6, and the lower end is movably inserted into the V-shaped fixing column 7 at the bottom of the pool; The support 76 is reinforced to obtain a more solid, reliable, and durable use effect; there are two semi-cylindrical sliding sleeves 4, which are symmetrically installed on both sides of the base 54 of the tripod bracket 5; the tripod bracket 5. The semi-cyli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com