Waste SBS (Styrene Butadiene Styrene) modified asphalt recycling method

A modified asphalt and waste technology, which is applied in the direction of recycling technology, building components, building insulation materials, etc., can solve the problems of increasing the environmental protection of recycled asphalt pavement, reducing construction costs, and not being environmentally friendly, so as to simplify the recycling process and reduce Construction cost, environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1~4

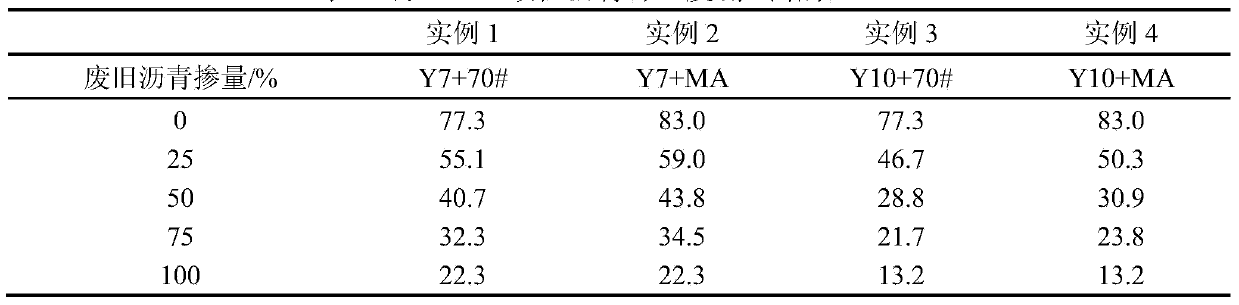

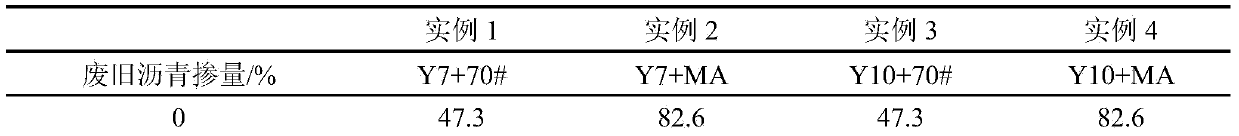

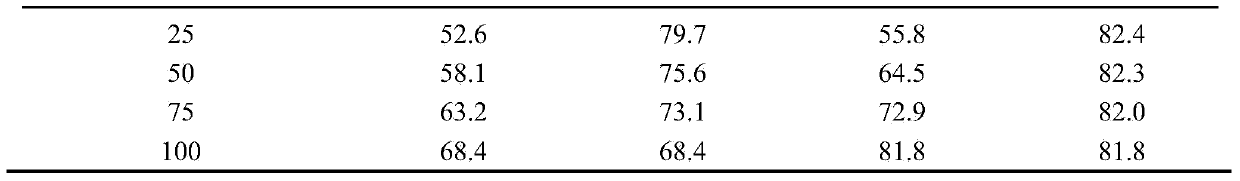

[0025]The waste SBS modified asphalt recovered from a 7-year service SBS modified asphalt pavement in Jilin Province is selected as Y7, and the waste SBS modified asphalt recovered from a 10-year service SBS modified asphalt pavement in Jilin Province is selected and marked as Y10, in order to reflect the regeneration effect of SBS modified asphalt on waste asphalt, in addition to adding SBS modified asphalt MA, the control group was set to add 70# asphalt to regenerate waste asphalt, that is to say, four groups of recycled asphalt were obtained: Example 1 is 70# asphalt regeneration Y7, example 2 is SBS modified asphalt regeneration Y7, example 3 is 70# asphalt regeneration Y10, example 4 is SBS modified asphalt regeneration Y10. Heat waste SBS-modified asphalt and fresh SBS-modified asphalt to 170°C, heat fresh 70# asphalt to 150°C, add waste SBS-modified asphalt to fresh asphalt according to the above four regeneration schemes, and waste SBS-modified The ratio of permanent ...

example 5~10

[0036] The asphalt mixture obtained from the waste asphalt pavement of a certain expressway in Jilin Province, which has been in service for 7 years, is used to remove impurities, crushed, dried and other processes. In T0726, the method for recovering asphalt from asphalt mixture (Abson method) recycles waste SBS modified asphalt mixture to obtain waste SBS modified asphalt. After heating the fresh SBS modified asphalt and the waste SBS modified asphalt to 170 °C respectively, the waste SBS modified asphalt was mixed according to the mass ratio of 0:100, 10:90, 20:80, 30:70, 40:60 and 50 : Mix with fresh SBS modified asphalt at a ratio of 50, and stir at a speed of 140r / min while mixing, keep the temperature of the asphalt at 170°C, stir at a speed of 140r / min for 15min, and then use a high-speed shearing instrument at a speed of 3000r / min min at a speed of shearing for 30 min to obtain regenerated SBS modified asphalt, which are respectively recorded as Example 5-Example 10. ...

example 11~16

[0042] The asphalt mixture obtained from the waste asphalt pavement of an expressway that has been in service for 10 years in Jilin Province is used, and then after impurity removal, crushing, drying and other processes, according to the "Experimental Regulations for Asphalt and Asphalt Mixtures in Highway Engineering" (JTJ052-2000) T0726 Method for recovering asphalt from asphalt mixture (Abson method) Recycling waste SBS modified asphalt mixture to obtain waste SBS modified asphalt. After heating the fresh SBS modified asphalt and the waste SBS modified asphalt to 170 °C respectively, the waste SBS modified asphalt was mixed according to the mass ratio of 0:100, 10:90, 20:80, 30:70, 40:60 and 50 :50 to mix with fresh SBS modified asphalt, and stir at a speed of 140r / min while adding, the asphalt mixing process is completed within 5min, keep the temperature of the asphalt at 170°C, and stir at a speed of 140r / min for 15min, Then use a high-speed shearer to shear at a speed of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com