Graphene-containing polyolefin high semiconductive shielding material for cables and preparation method thereof

A graphene and polyolefin technology, applied in the field of medium and high voltage power transmission and distribution cable materials and their preparation, can solve the problems of insufficient particle size, unsatisfactory carbon black conductivity, unsatisfactory cable shielding and equalizing electric field effect, etc. Improve electrical properties, increase the effect of the homogenizing electric field, increase the effect of the homogenizing electric field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

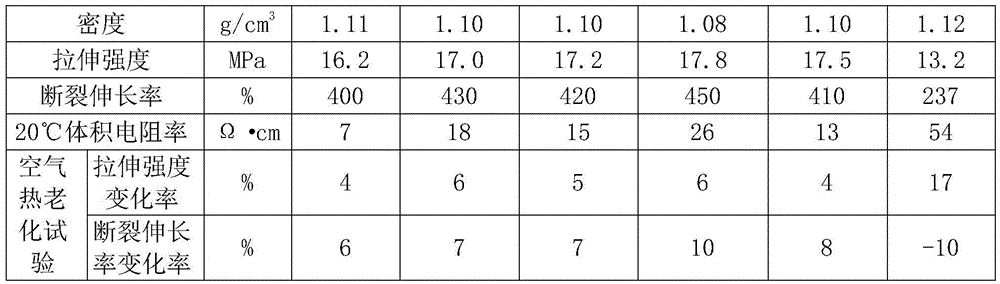

Examples

preparation example Construction

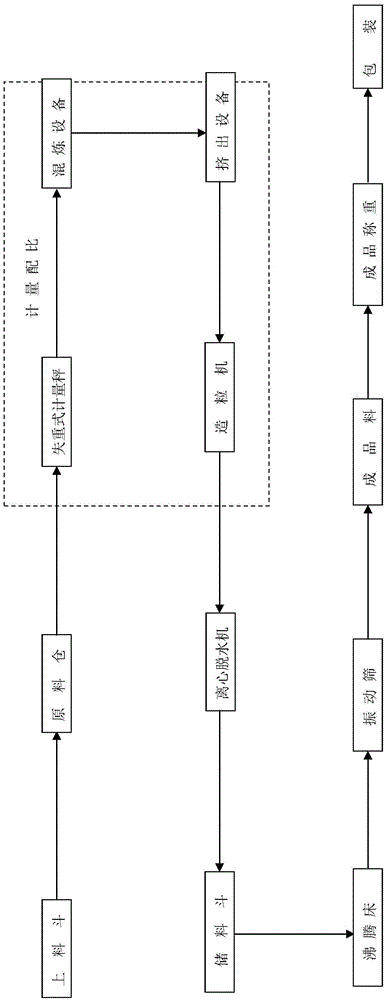

[0025] The preparation method of the polyolefin high semiconductive shielding material (shielding material) containing graphene for cables of the present invention, such as figure 1 shown, including the following steps:

[0026] 1. Mixing, ethylene-vinyl acetate copolymer EVA, graphene powder with a particle size not greater than 10 μm, white oil, antioxidant 4,4'-thiobis(6-tert-butyl-3-methylphenol) and zinc stearate, respectively loaded into the raw material warehouse through the upper hopper, and continuously weighed with a weight loss weighing scale. , graphene powder 3%~10%, white oil 3%~6%, antioxidant 0.5%~1%, zinc stearate 0.3%~0.6%, added to WF140- In the mixing zone of the 180-type reciprocating mixing extrusion granulation unit, stir and mix at a speed of 150-200rpm for 1-2 minutes to obtain a uniformly mixed mixture.

[0027] The WF140-180 reciprocating mixing extrusion granulation unit used in this example is a set of multi-functional continuous equipment, which...

Embodiment 1

[0044] 1. The mass percentage content is: EVA83%, graphene powder 10%, white oil 6%, antioxidant 0.5%, zinc stearate 0.5%. Stir and mix at 150 rpm for 2 minutes.

[0045] 2. For the first plasticization, the screw speed is controlled at 180rpm / min, and the first plasticization temperature is:

[0046] zone 1

Zone 2

District 3

District 4

District 5

85

105

115

100

90

[0047] For the second plasticization, the screw speed is 120rpm, and the second plasticization temperature is:

[0048] zone 1

Zone 2

nose

85

85

105

[0049] 3. The temperature is 105° C., the pressure is 5.0 MPa, and cylindrical particles with a diameter of 3.5 mm and a height of 3 mm are made.

[0050] 4. The rotating speed is 1080rmp, the time is 23min, dehydration.

[0051] 5. Fluidized bed drying, drying at 50°C, cooling, and screening to obtain graphene-containing polyolefin high semiconductive shielding materia...

Embodiment 2

[0053] 1. The mass percentage content is: EVA resin 86%, graphene powder 7%, white oil 5.4%, antioxidant 1%, zinc stearate 0.6%. Stir and mix at 200 rpm for 1 minute.

[0054] 2. For the first plasticization, the screw speed is controlled at 200rpm / min, and the first plasticization temperature is:

[0055] zone 1

Zone 2

District 3

District 4

District 5

87

108

120

103

92

[0056] For the second plasticization, the screw speed is 150rpm, and the second plasticization temperature is:

[0057] zone 1

Zone 2

nose

87

89

107

[0058] 3. The temperature is 107° C., the pressure is 6.5 MPa, and cylindrical particles with a diameter of 3.5 mm and a height of 3 mm are made.

[0059] 4. The rotating speed is 1140rpm, the time is 25min, dehydration.

[0060] 5. Fluidized bed drying, drying at 48°C, cooling, and screening to obtain graphene-containing polyolefin high semiconductive shielding ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com