Aluminum foil polishing machine

A technology of aluminum foil polishing machine and motor, which is applied in the direction of calender, paper machine, textile and paper making, etc., can solve the problems of time-consuming and labor-consuming, low efficiency, high damage rate, etc., and achieve the advantages of convenient operation, high brightness and smooth surface Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

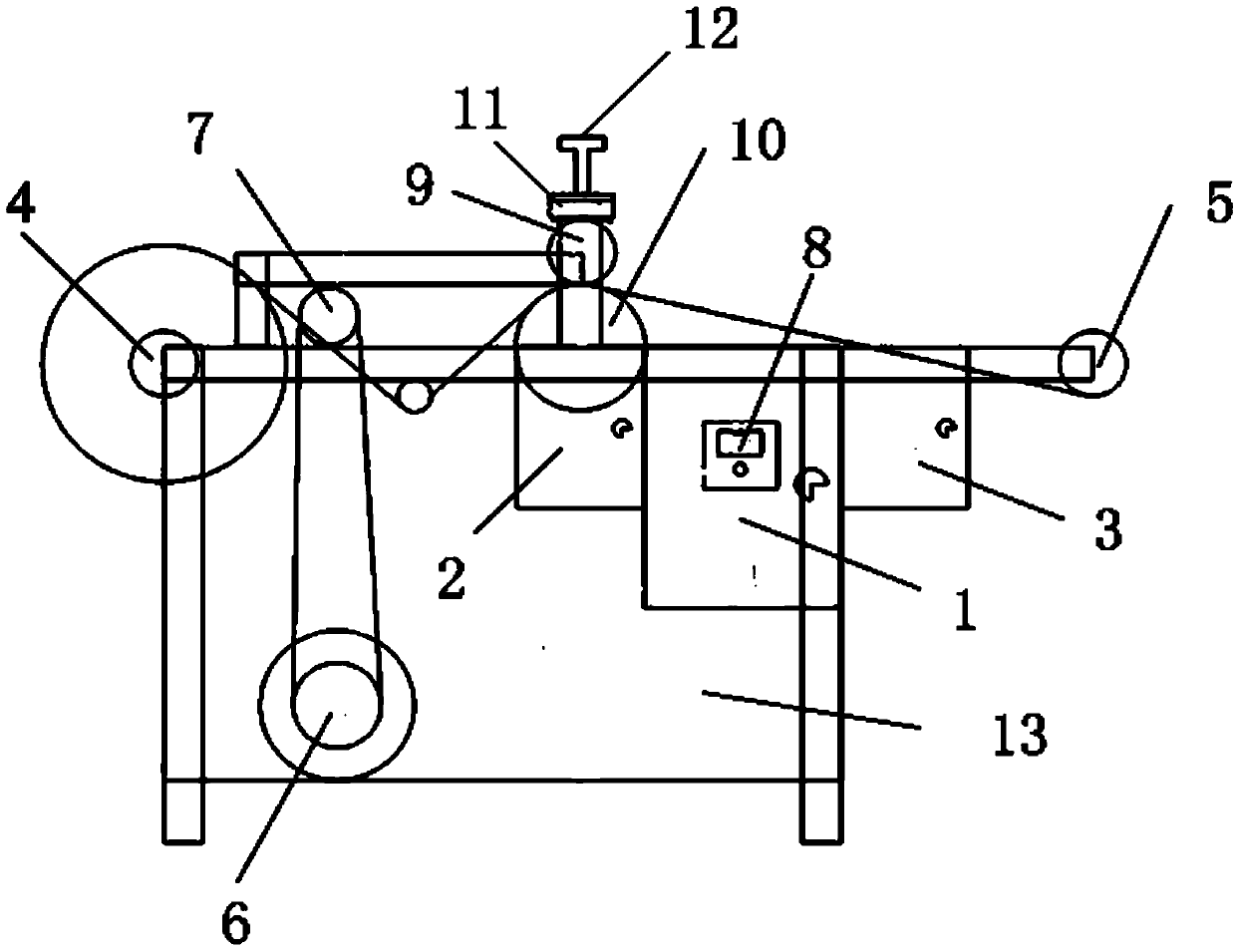

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] Such as figure 1 As shown, an aluminum foil polishing machine includes a platform frame 13, a motor 6, a pressure roller 9, a friction roller 10, an oil tank 11, a pressure regulating valve 12, a speed regulator 8, and a computer control box 1. The left side of the platform frame 13 is equipped with a feeding air rising shaft 4, and the right side of the platform frame 13 is equipped with a receiving air rising shaft 5. Motor 6 is installed in the platform frame 13, is provided with transmission wheel 7 on the top of motor 6, and transmission wheel 7 is connected with motor 6 by transmission belt, and the upper end of platform frame 13 is provided with friction roller 10, and friction roller 10 passes transmission belt and transmission wheel 7 phase connection, a pressure roller 9 is arranged directly above the friction roller 10, the pressure roller 9 and the ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap