Track bed, construction method thereof, and high polymer vibration isolation bearing replacement method

A vibration isolation bearing and polymer technology, applied in the field of rail transit, can solve the problems of affecting traffic, cumbersome processes, inconvenient replacement of vibration damping devices, etc., and achieve the effect of convenient replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below with reference to the accompanying drawings and preferred embodiments. However, it should be noted that many of the details listed in the specification are only for readers to have a thorough understanding of one or more aspects of the present invention, and these aspects of the present invention can be implemented even without these specific details.

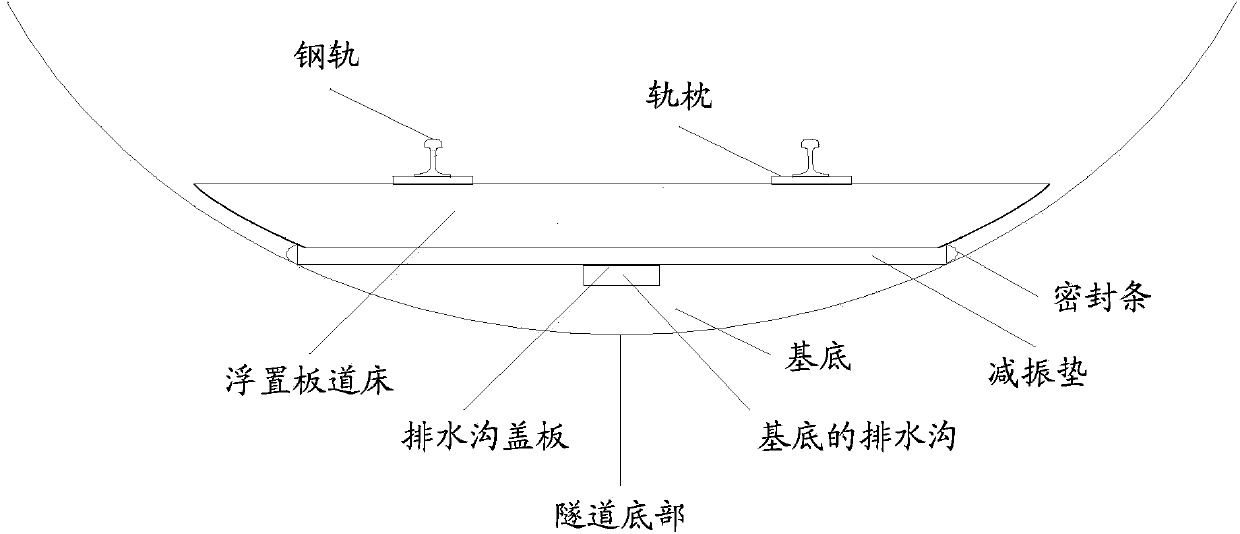

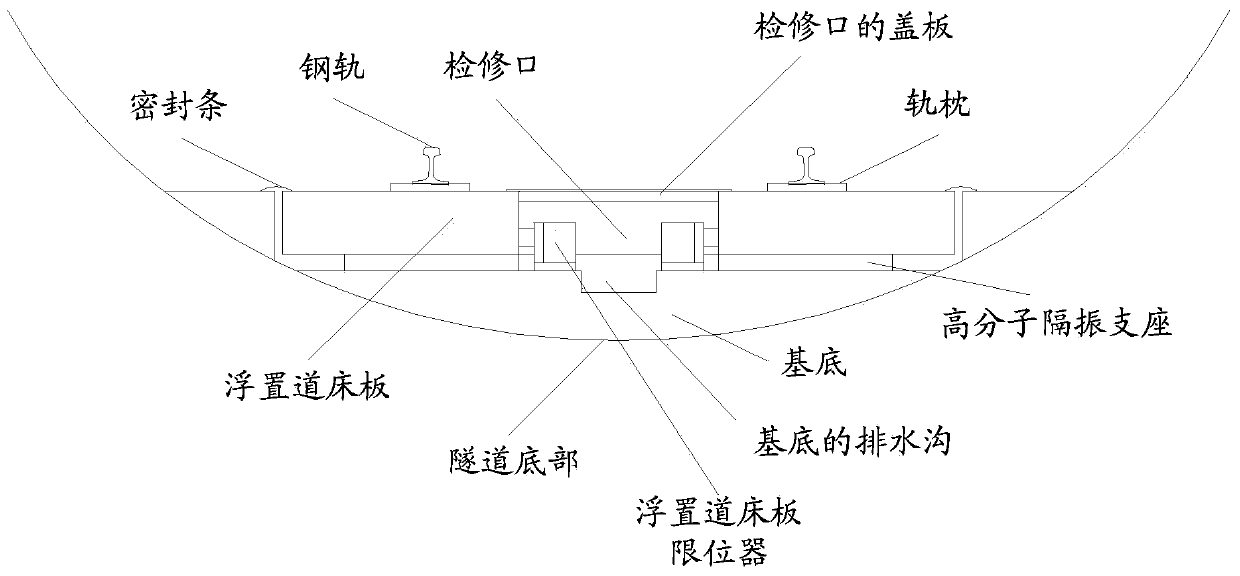

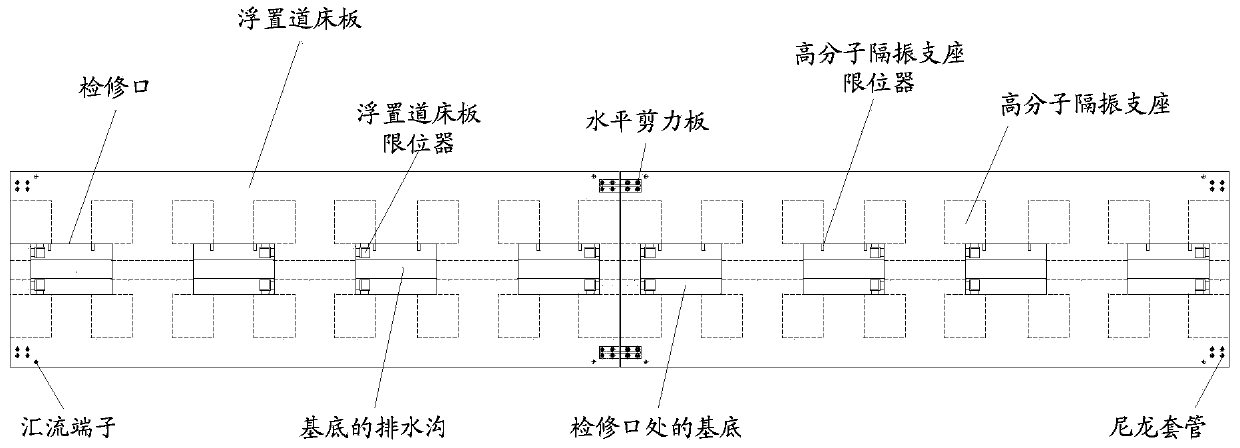

[0049] The inventor of the present invention considers that a polymer vibration isolation bearing with a set size can be prefabricated according to the requirements of the subway environmental impact assessment and the specific construction plan as a vibration damping device; an inspection port is opened in the floating slab track bed to form a floating track bed slab, and the The size of the inspection port in the horizontal section is greater than the size of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com