Mining roadway coal pillar reinforcing method

A technology for mining roadways and coal pillars, applied in tunnels, ground mining, tunnel lining, etc., to achieve the effect of ensuring safe and efficient production, large width and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

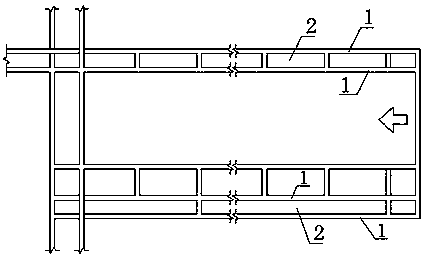

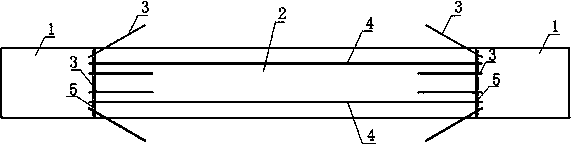

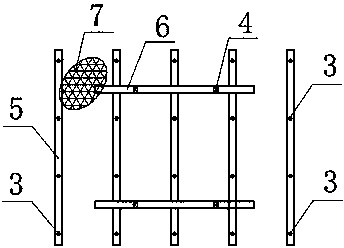

[0013] The present invention provides a method for strengthening the inter-lane coal pillar of the mining roadway. Since the multi-lane layout is adopted in the mining face, the inter-alley coal pillar (2) is formed. Firstly, the conventional anchor belt net is used to support and reinforce the coal pillar (2). Then drill holes on the coal side and penetrate the coal pillar, penetrate the extension bolt (4), lay channel steel beams or steel strips (6) on both sides of the extension bolt (4), and the steel strip or groove The steel girder is pressed on the steel belt (5) that has been constructed, and the mesh (7) and the steel belt (5) are tightly connected into a whole to enhance the surface protection effect on the coal pillar. At the same time, high prestress is applied to both ends of the extended anchor rod (4), so that the coal pillar is in a three-dimensional stress state, and the deformation of the coal pillar can be effectively controlled in the early stage. Due to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com