Wind generating set barring assembly and barring method

A technology for wind turbines and wind turbines, which is applied to wind turbine components, wind turbines, wind power generation, etc., can solve the problems of time-consuming and labor-intensive reliability of wind turbines, construction is affected by the working environment, and damage to the unit. , to achieve the effect of low cost, simple structure and low risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings.

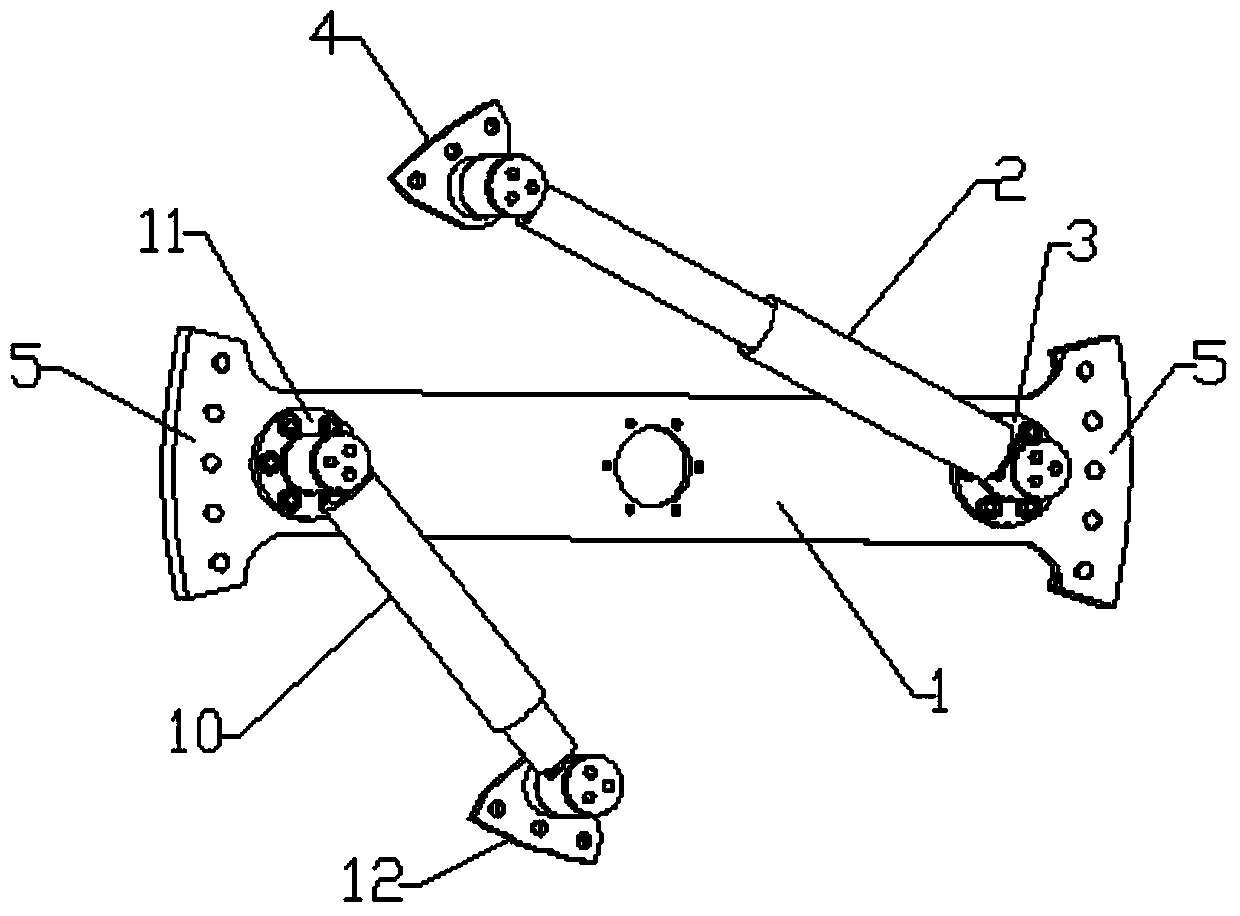

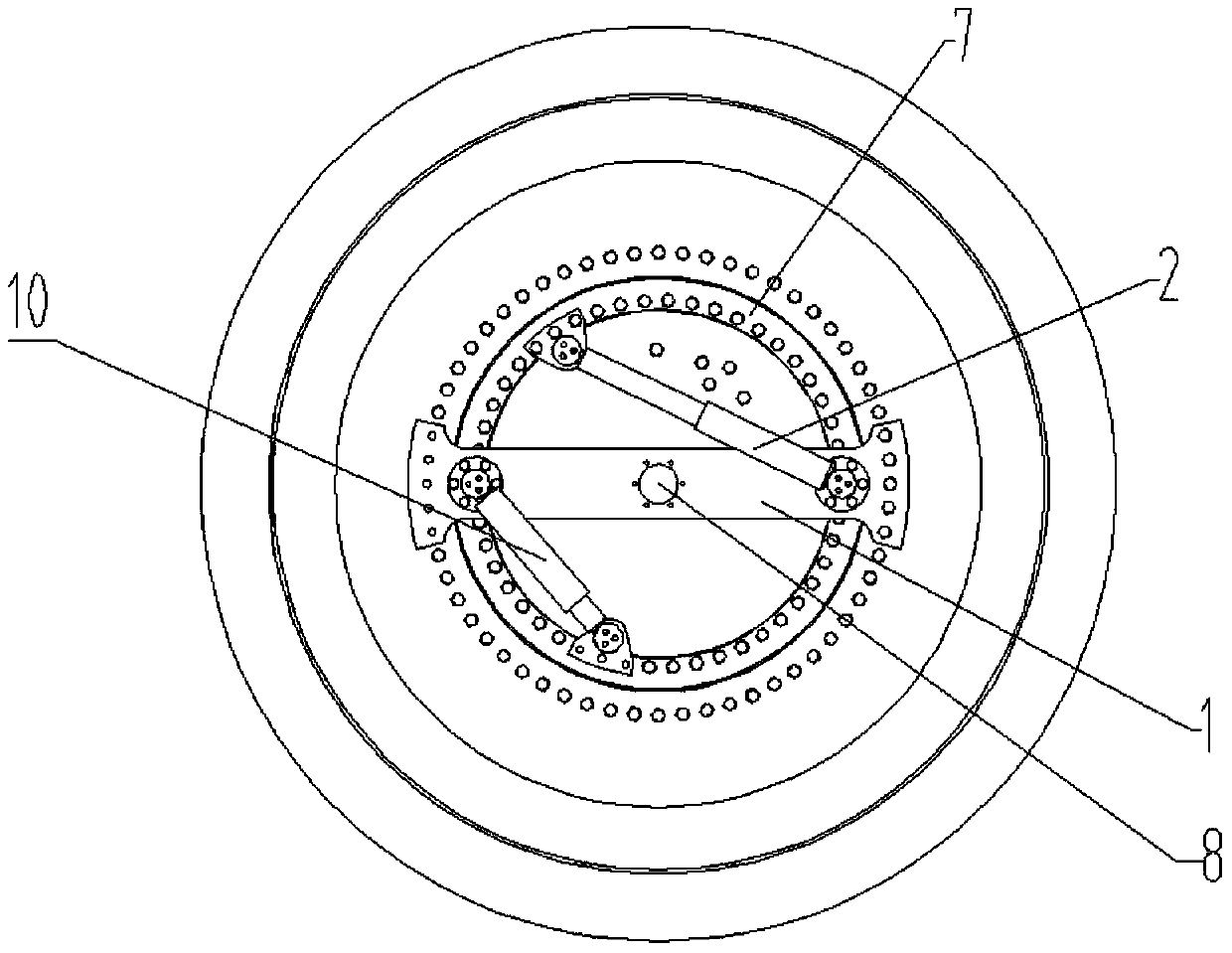

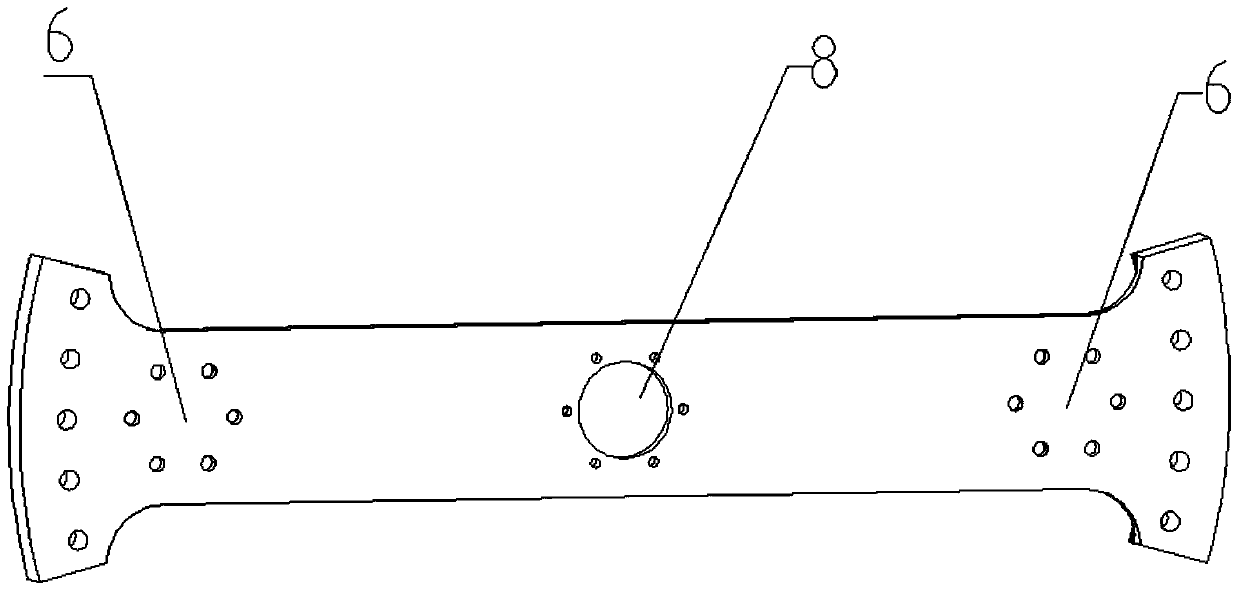

[0057] The wind power generator set barring assembly provided in this embodiment at least includes a support beam 1 , a first hydraulic cylinder 2 , a first connecting base 3 and a second connecting base 4 . The support beam 1 is provided with a connection part 5 for connecting with the non-rotating parts of the wind power generator, and a connection part 6 for fixed connection with the first connection base 3, and the first connection base 3 is used for connecting the The outer cylinder of the first hydraulic cylinder 2 is connected to the support beam 1 , and the second connection base 4 is used to connect the telescopic rod of the first hydraulic cylinder 2 to the wind turbine rotor 7 .

[0058] Before the assembly is actually used for wind power generating set barring, the supporting beam 1 , the first hydraulic cylinder 2 , the first connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com