Fan gear box space failure predicating method based on temperature data

A technology for temperature data and fault prediction, which is used in machine gear/transmission mechanism testing, electrical digital data processing, special data processing applications, etc., and can solve problems such as large economic losses and long downtime.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] The realization of technical scheme of the present invention is divided into three steps:

[0076] 1. Use the regression analysis method to preprocess the temperature data;

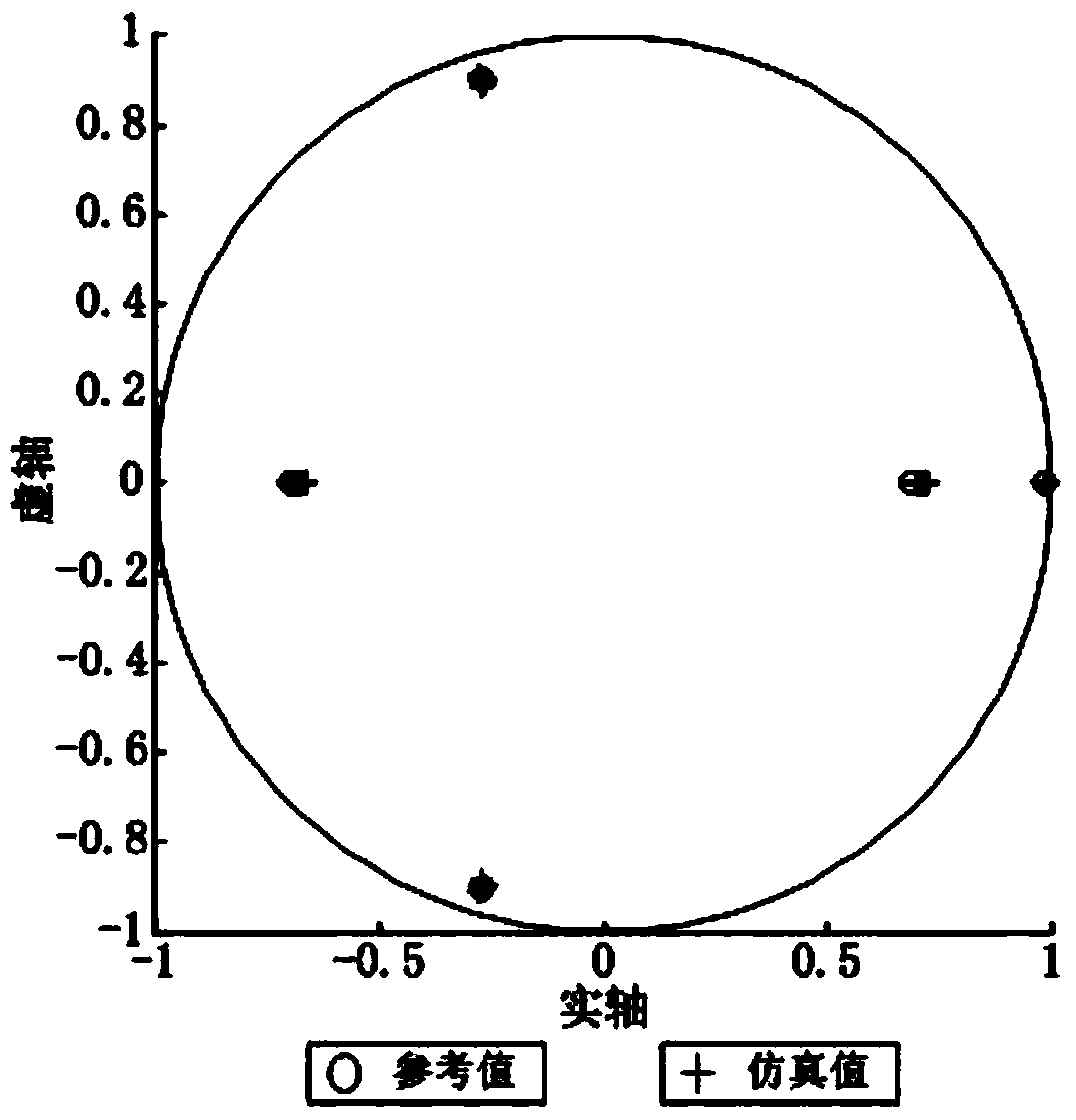

[0077] 2. Use the subspace method to identify the parameters of the stochastic state-space model;

[0078] 3. Realize the early warning of the gearbox failure.

[0079] 1 Preprocessing of temperature data

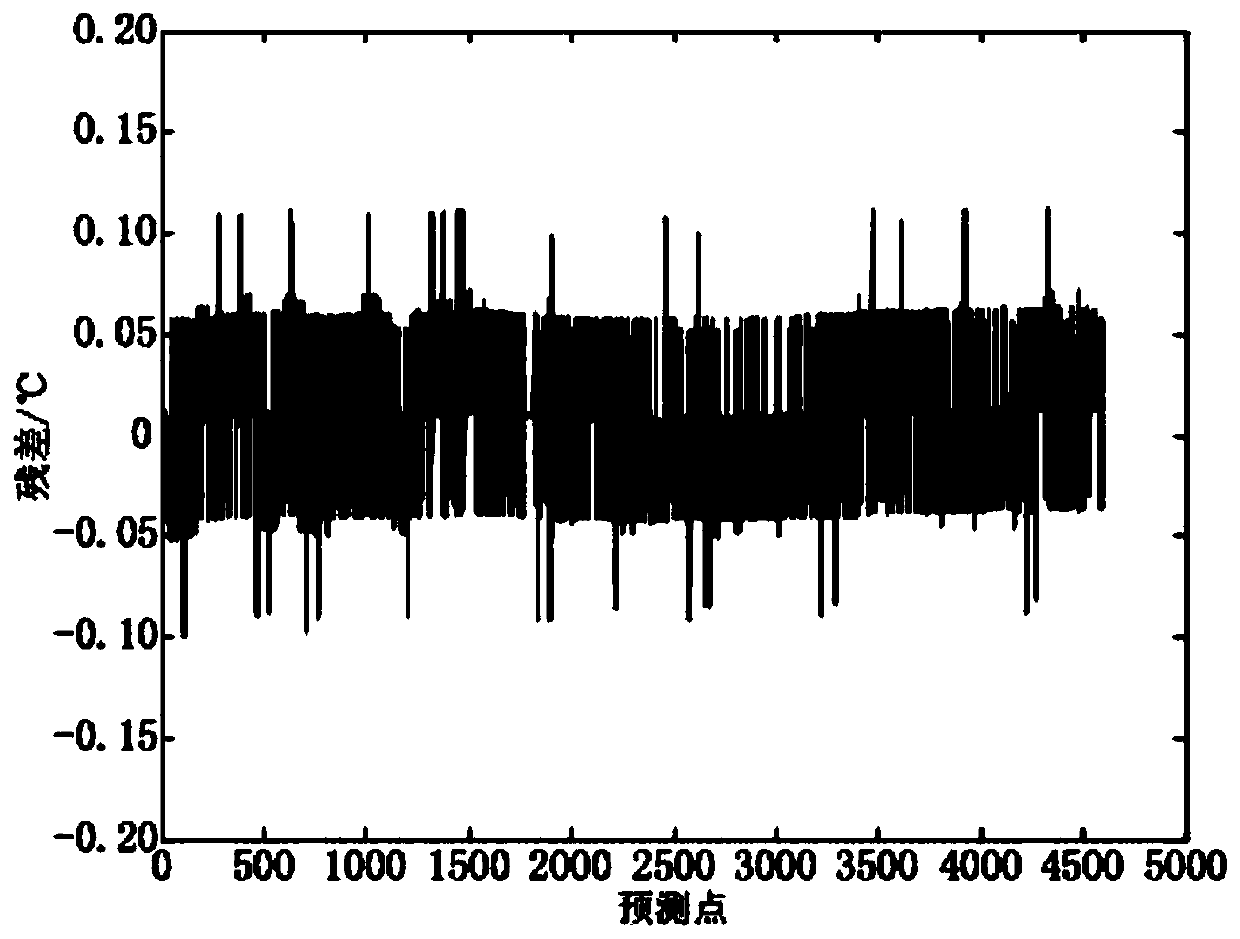

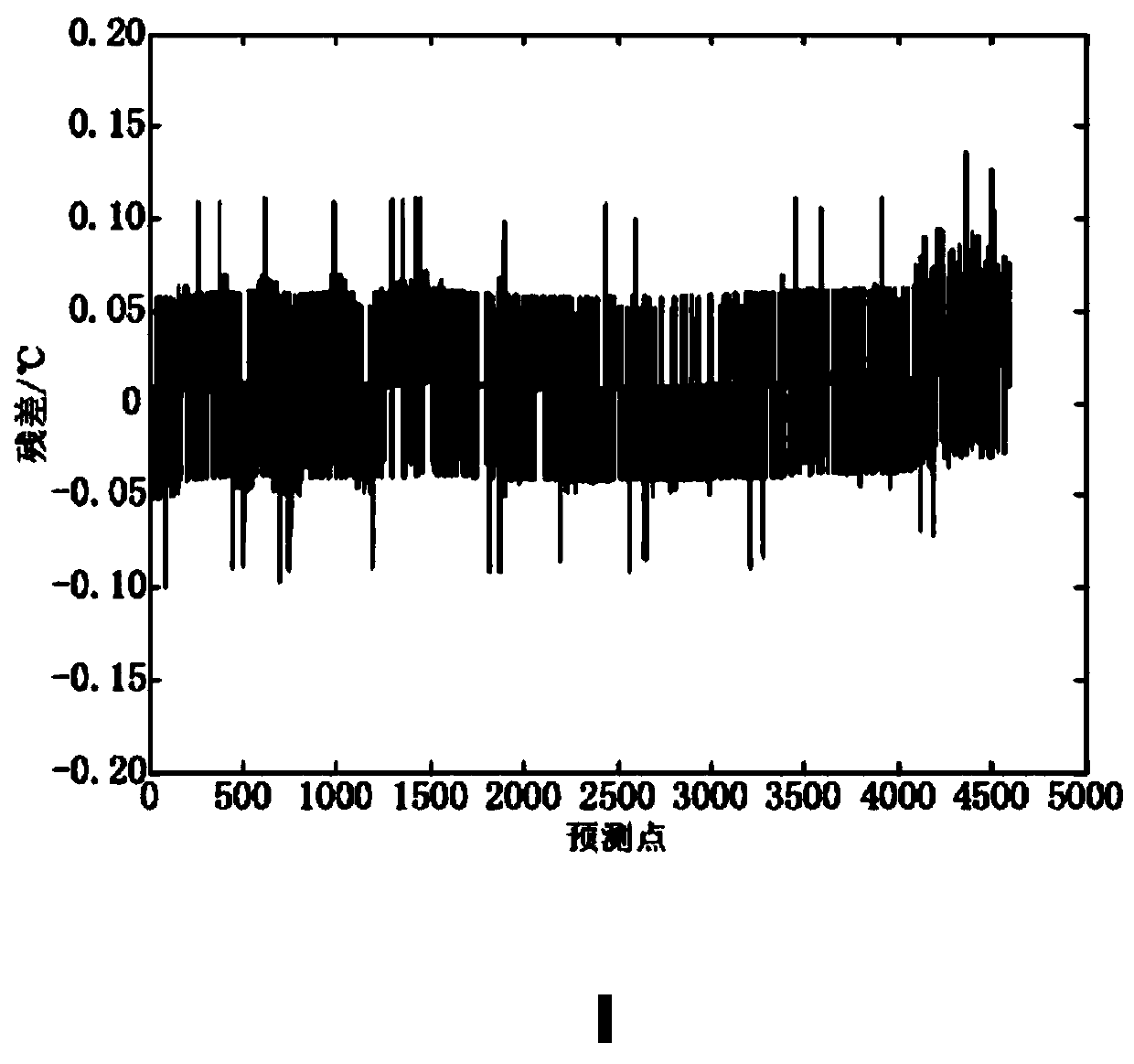

[0080] The subspace method is a time-domain analysis method, which is suitable for dealing with high-frequency signals like vibration signals that fluctuate up and down a certain value. The regression analysis method is used to predict the temperature data in a single step, and the difference between the actual value and the predicted value is obtained, which is called the residual, and the residual is used as the observation Y of the stochastic state space model.

[0081] 1.1 Multiple linear regression model

[0082] The general form of a multiple linear regression model is as follows:

[...

Embodiment 2

[0141] 1. Use the regression analysis method to preprocess the temperature data;

[0142] 1. Find the estimated value of the regression parameter

[0143] Using a period of ambient temperature T e , gearbox oil temperature T o , gear bearing temperature T b Estimate regression model parameters. Suppose the temperature value T at time k k and ambient temperature values at the previous 2 moments (T e(k-1) , T e(k-2) ), the gearbox oil temperature at two moments before time k (T o(k-1) , T o(k-2) ) related to the gear bearing temperature (T b(k-1) , T b(k-2) )related. T k is the average of the gearbox oil temperature and the gear bearing temperature.

[0144] If n groups of such monitoring data have been obtained (T ie1 , T ie2 , T io3 , T io4 , T ib5 , T ib6 ;T i ), i=1,2,…,n, then the regression model is

[0145] T 1 = β ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap