Muffling device for supersonic combustion ramjet test bench

A ramjet, supersonic combustion technology, applied in the direction of engine testing, measuring devices, machine/structural component testing, etc., to achieve the effects of eliminating jet noise, working stably, and eliminating broadband jet noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined arbitrarily with each other.

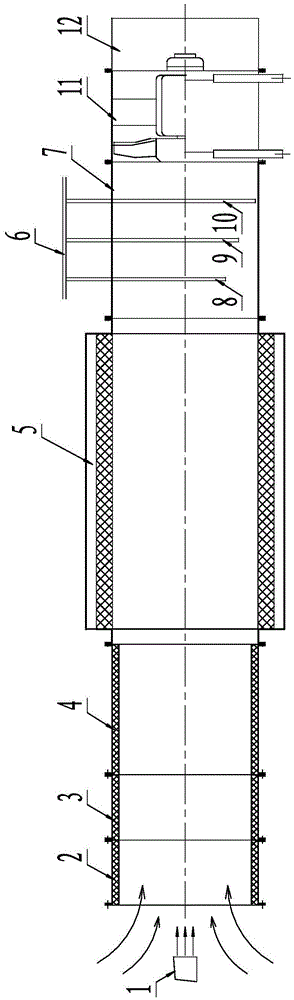

[0022] like figure 1 As shown, the muffler device for the supersonic combustion ramjet engine test bench according to the embodiment of the present invention includes a muffler system, a cooling water injection system and a fan exhaust system connected in a straight line in sequence, and the three systems all have The injection channel is coaxial, and the muffler system is arranged directly behind the combustion chamber tail end 1 of the supersonic combustion ramjet engine and close to the combustion chamber tail end 1 of the supersonic combustion ramjet engine.

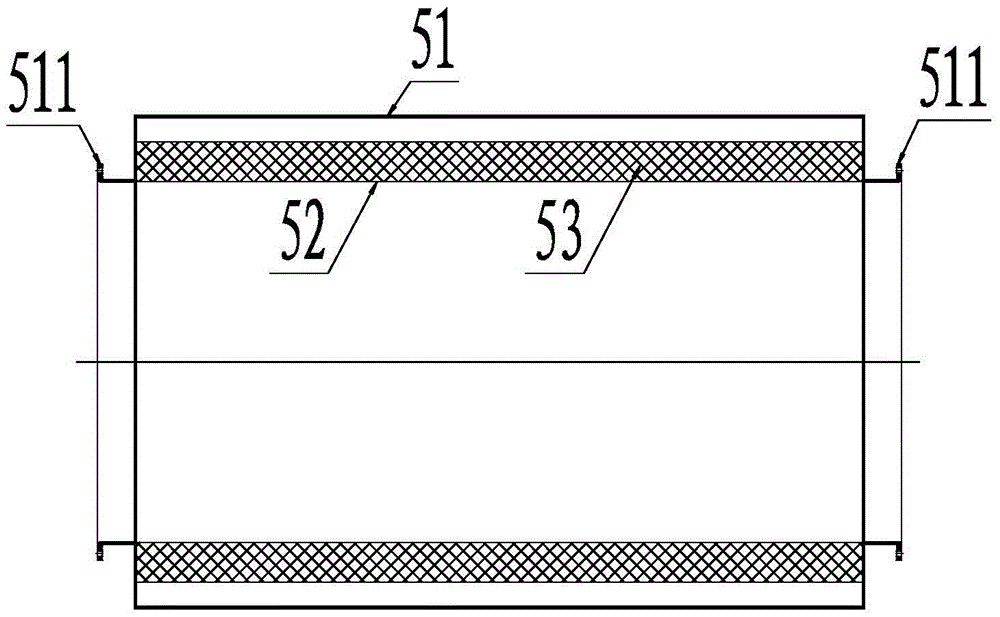

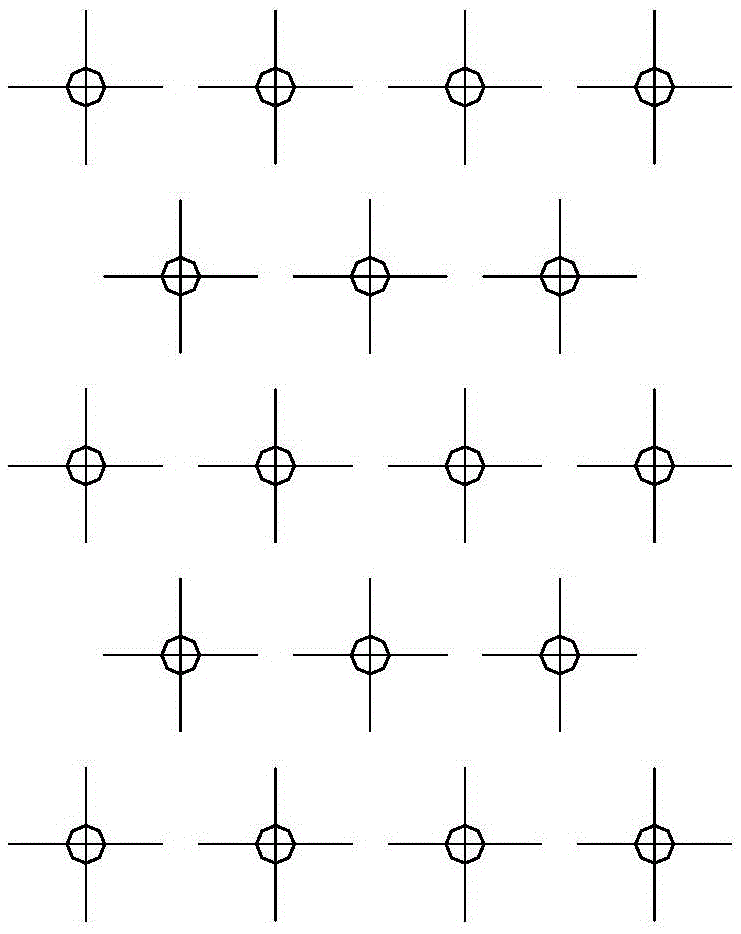

[0023] The muffler system consists of 4 mufflers 2, 3, 4 and 5 connected in series. Among them, muffler 5 is the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com