A method for measuring the moisture content of tobacco and its tobacco products

A technology for tobacco products and determination methods, applied in the direction of weighing by removing certain components, to achieve the effects of ensuring accuracy, good repeatability, and shortening detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The thermogravimetric analyzer adopted in this embodiment is the Q500 thermogravimetric analyzer of American TA company (but not therefore

[0030] The model of the thermogravimetric analyzer is limited, and those skilled in the art can use other types of thermogravimetric analyzers (other types of thermogravimetric analyzers commonly used in this field can be used), and the total flow rate of high-purity nitrogen (99.99%) is 100mL / min.

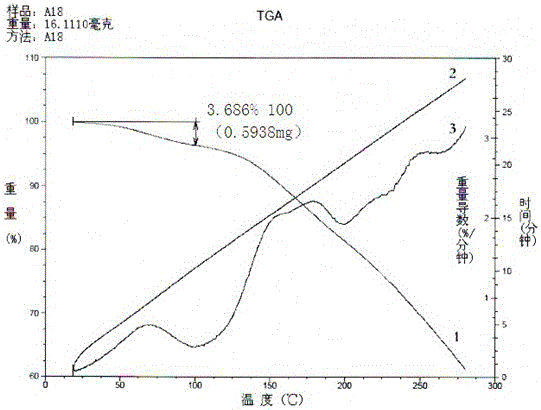

[0031] Tobacco sample A18 is placed in the thermogravimetric analyzer for temperature programming, when the tested tobacco sample is heated

[0032] When losing moisture during the process, record the thermogravimetric curve, and calculate the moisture content in the tested tobacco sample according to the weight loss; The sample size was 16.1110 mg. The test results are attached figure 1 As shown, curve 1 is the weight loss curve, curve 2 is the temperature-time relationship curve, and curve 3 is obtained by deriving the percentage o...

Embodiment 2

[0034] Analytical instrument is with embodiment 1. The total flow of high-purity nitrogen (99.99%) is 100mL / min, the flow of divided samples is 90mL / min, and the balance is 10mL / min.

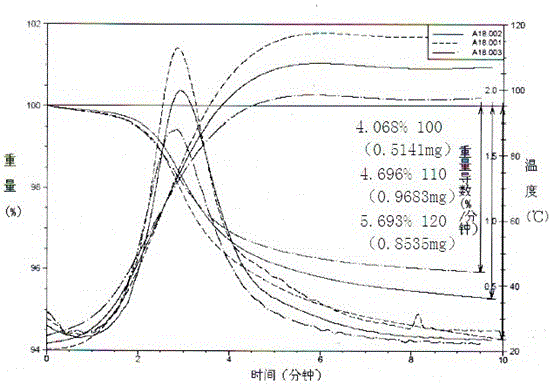

[0035] The present invention conducts continuous experiments on the same tobacco sample and a large number of different tobacco samples at different heating rates, and concludes that moisture detection of tobacco and its products can be established at a heating rate of 50°C / min to obtain more accurate results. And further increase the temperature from room temperature (25°C) to different temperatures at a heating rate of 50°C / min, set the temperature for 8 minutes, count, compare and analyze the experimental results, and confirm that the temperature can be increased to 110°C to obtain accurate detection results. The experimental process and results can not be repeated here one by one, the present embodiment is attached figure 2 The thermogravimetric curves of heating from room temperature (25°...

Embodiment 3

[0038]Analytical instrument is with embodiment 1. The total flow of high-purity nitrogen (99.99%) is 100mL / min, the flow of divided samples is 90mL / min, and the balance is 10mL / min.

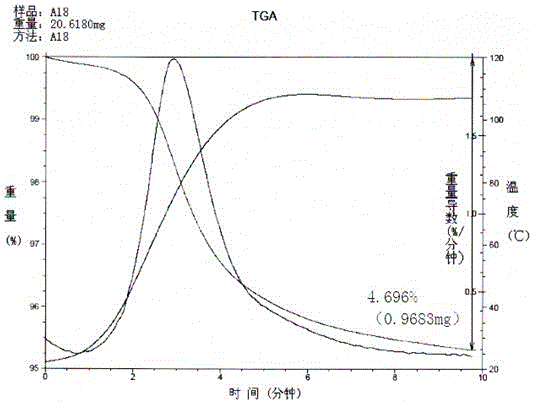

[0039] For sample A18, the sample volume for each analysis is 20.6180mg; the temperature is raised from room temperature (25°C) to 110°C at 50°C / min; the constant temperature is 8min, and the running time is 9.8min. The results of the analysis are attached image 3 shown. attached by image 3 It can be seen that the moisture content of the A18 sample is 4.70%; the moisture content of the same batch of samples A18 tested by the oven method (YC / T 31-1996) is 4.74%, and the results are very close. However, the sample used for the oven method is 2-3g, which takes about 4 hours (it takes about 2 hours to bake the weighing dish).

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com