Method for monitoring tea production in real time by adopting near infrared spectrum

A near-infrared spectroscopy, real-time monitoring technology, applied in measurement devices, material analysis by optical means, instruments, etc., can solve the problems of cumbersome operation and long time, and achieve the effect of rapid adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

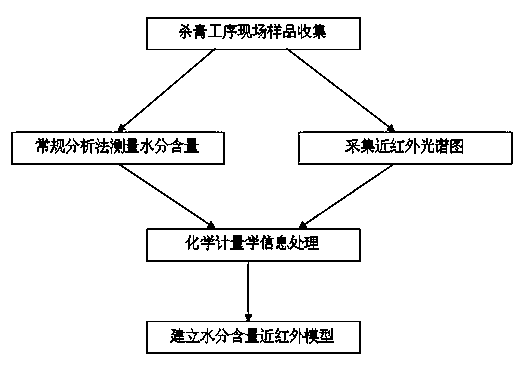

Method used

Image

Examples

Embodiment Construction

[0020] (1) Preparation of tea samples: 200 grams of tea samples were collected at various production stages (such as before, after electric heating, after microwave finishing, etc.), numbered, packed in aluminum foil sample bags, sealed and refrigerated;

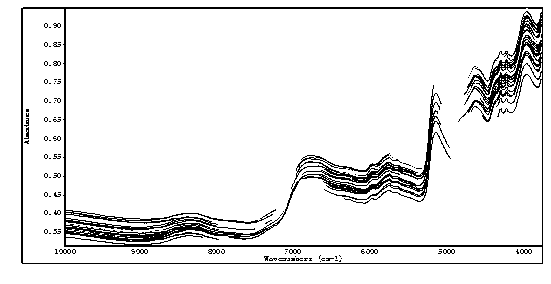

[0021] (2) Collection of near-infrared spectra: Antaris II near-infrared spectrometer produced by ThermoFisher in the United States is used. The software adopts standard workflow (SOP) and analysis methods based on Workflow to collect diffuse reflectance spectra of tea samples. The specific method is to place the tea samples in the instrument-specific quartz opening sample cup (4.78cm diameter), and rotate the sample cup during collection to reduce the error caused by sample inhomogeneity. The acquisition parameters are: the number of scans is 64, the resolution is 8cm-1, and the spectral range is 10000-3800cm-1. High-sensitivity InGaAs detector, automatically collect background, see attached figure 2 ;

[0022] (3) Diffu...

PUM

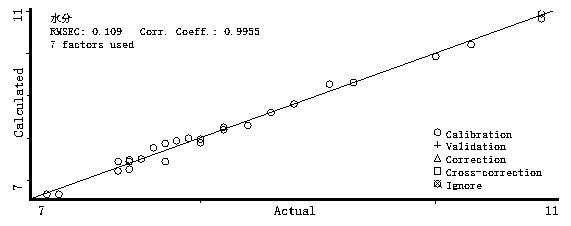

| Property | Measurement | Unit |

|---|---|---|

| correlation coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com