Evaluation method for sealing agent of thermal spraying coating

An evaluation method and technology of sealing agent, applied in the direction of coating, metal material coating process, molten spraying, etc., can solve the problems of long test period, corrosion resistance, cumbersome test preparation, etc., to achieve verification of heat resistance, Increase the effect of heating equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

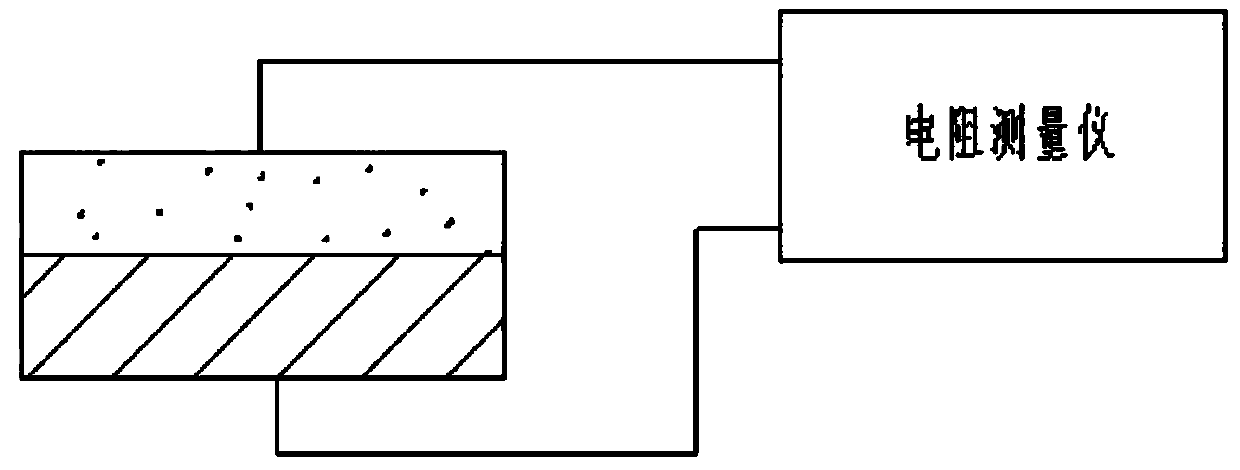

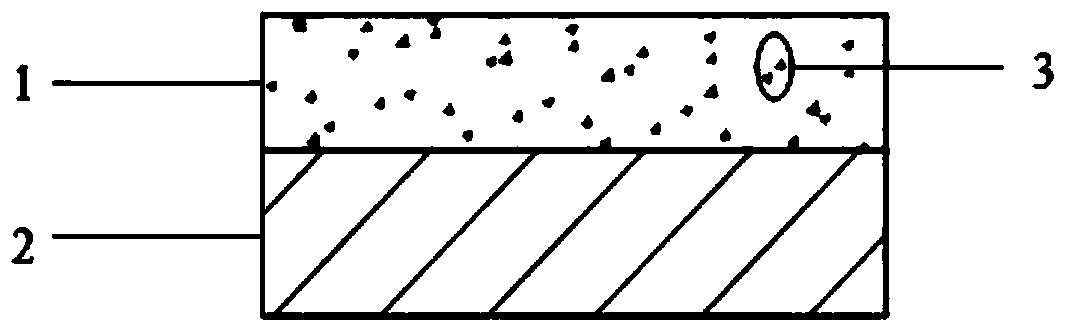

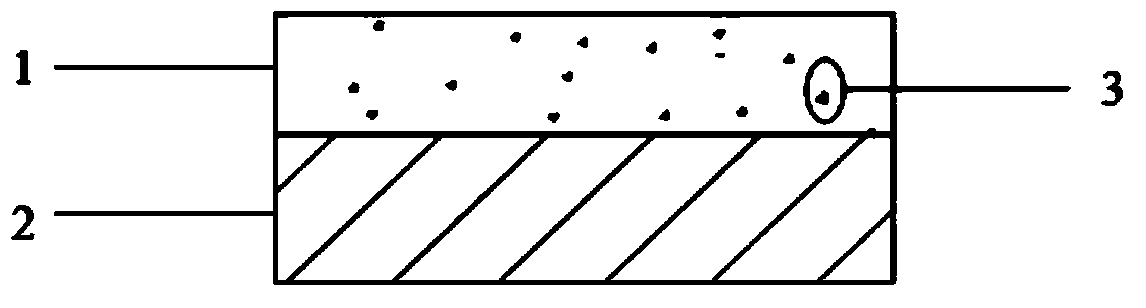

[0042] This embodiment provides three kinds of sealing agents and evaluation examples with unsealed coating as a reference. The specific process is as follows:

[0043] ①. Insulation coating preparation, AT20 spray powder is selected, and plasma spraying equipment is used for spraying. The spraying parameters are: I: 700A, Ar: 45psi, H 2 : 70psi, carrier gas: 50psi, powder disc speed: 3.0 rpm, gun distance: 95mm. Coating thickness 0.30mm, four pieces in total.

[0044] ②, Sealing treatment, the three sealing agents of alkyd varnish, amino alkyd, and polytetrafluoroethylene are used for sealing treatment according to the instructions, and the next step is performed after thorough curing.

[0045] ③. Polishing treatment. Polishing treatment is performed on the cured sample and the unsealed sample, and the coating is polished off by about 0.1mm.

[0046] ④ Soaking, soak the four polished samples in 5% NaCl solution for 2 hours.

[0047] ⑤. Measurement: Wipe the soaked sample cle...

Embodiment 2

[0050] Same as embodiment 1, but in its step 1, the insulating coating selects AT13 spraying powder for use, and concrete composition is: TiO 2 : 13.0%, Al 2 o 3 :margin. The coating thickness is 0.5 mm, and the coating thickness after polishing is 0.4 mm.

[0051] The evaluation part of step 6 is as follows:

[0052] The resistance of the unsealed sample after immersion is 0-2 megohm, the resistance of the polytetrafluoroethylene sample is 3-5 megohm, the alkyd varnish sample is 8-30 megohm, and the amino alkyd is 40 ~65 megohms. Taking 5 megohms as the critical resistance value, it can be considered that the two sealing agents, alkyd varnish and amino alkyd, meet the requirements for coating use, and amino alkyd is better than alkyd varnish.

Embodiment 3

[0054] Same as Example 1, but the thickness of the coating in step 1 is 0.4 mm; the coating is polished off by about 0.15 mm in step 3.

[0055] The evaluation part of step 6 is as follows:

[0056] The resistance of the unsealed sample after immersion is 0-0.5 megohm, the resistance of the polytetrafluoroethylene sample is 1-5 megohm, the alkyd varnish sample is 6-20 megohm, and the amino alkyd is 30-20 megohm. 55 megohms. Taking 5 megohms as the critical resistance value, it can be considered that the two sealing agents, alkyd varnish and amino alkyd, meet the requirements for coating use, and amino alkyd is better than alkyd varnish.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com