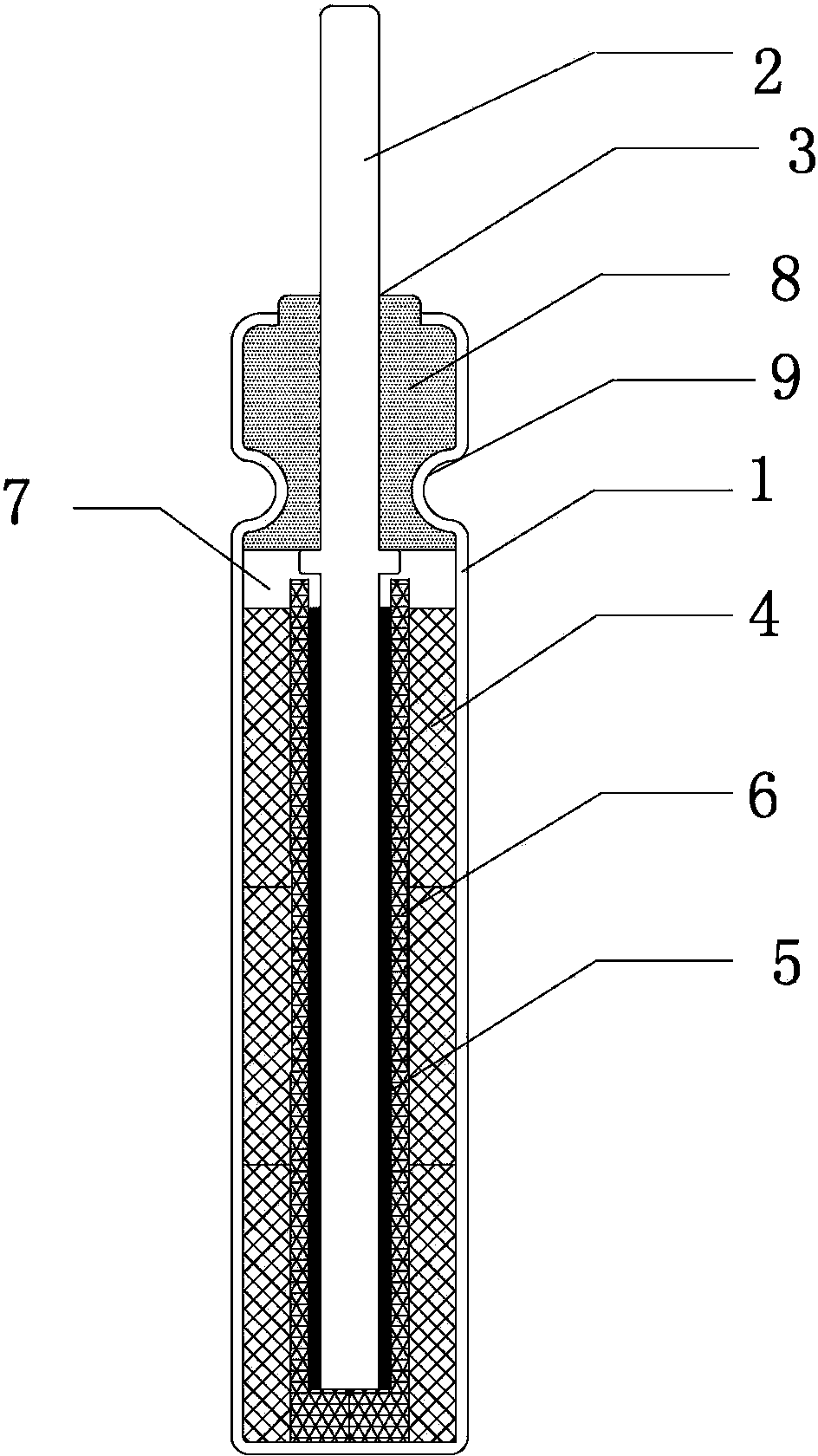

Lithium manganese needle-type battery and manufacturing method thereof

A manufacturing method and technology of lithium-manganese needles, which are applied to the electrodes of primary batteries, battery pack components, non-aqueous electrolyte batteries, etc., can solve problems such as inability to produce, difficult to increase, and small volume, so as to improve production efficiency and increase battery life. capacity, easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment one A method for making a lithium-manganese needle battery, characterized in that, comprising the following steps:

[0034] (1) Preparation of materials, production of positive electrode powder, weighing 40% of manganese dioxide, 3% of graphite powder, 3% of acetylene black, 1% of polytetrafluoroethylene, 3% of absolute ethanol, 50% of Water, put the manganese dioxide into the stainless steel box, and then put the stainless steel box with the manganese dioxide into the high-temperature oven, the temperature of the oven is 380°C, after baking for 8 hours, take it out and cool it at room temperature and seal it for later use ;

[0035] (2), dry mixing, dry mixing the manganese dioxide, graphite powder and acetylene black weighed in the first step, and the dry mixing time is 10 minutes;

[0036] (3) To prepare a sticky cleaner, add the anhydrous ethanol weighed in the first step into 60% PTFE and stir, then add a small amount of pure water at 60°C, and stir f...

Embodiment 2

[0046] Embodiment two A method for making a lithium-manganese needle battery, characterized in that, comprising the following steps:

[0047] (1) Preparation of materials, production of positive electrode powder, weighing 45% of manganese dioxide, 2% of graphite powder, 2% of acetylene black, 0.5% of polytetrafluoroethylene, 2% of absolute ethanol, 48.5% of Water, put the manganese dioxide into the stainless steel box, then put the stainless steel box with manganese dioxide into the high-temperature oven, the temperature of the oven is selected at 390°C, after baking for 10 hours, take it out and cool it at room temperature spare;

[0048] (2), dry mixing, dry mixing the manganese dioxide, graphite powder and acetylene black weighed in the first step, and the dry mixing time is 15 minutes;

[0049] (3) To prepare a sticky cleaner, add the anhydrous ethanol weighed in the first step into 60% PTFE and stir, then add a small amount of pure water at 60°C, and stir for 8 minutes...

Embodiment 3

[0059] Embodiment three A method for making a lithium-manganese needle battery, characterized in that, comprising the following steps:

[0060] (1) Preparation of materials, production of positive electrode powder, weighing 49% of manganese dioxide, 1% of graphite powder, 1% of acetylene black, 0.3% of polytetrafluoroethylene, 1% of absolute ethanol, 47.7% of Water, put the manganese dioxide into the stainless steel box, then put the stainless steel box with manganese dioxide into the high-temperature oven, the temperature of the oven is selected at 400°C, after baking for 15 hours, take it out and cool it at room temperature. spare;

[0061] (2), dry mixing, dry mixing the manganese dioxide, graphite powder and acetylene black weighed in the first step, and the dry mixing time is 20 minutes;

[0062] (3) To prepare a sticky cleaner, add the anhydrous ethanol weighed in the first step into 60% PTFE and stir, then add a small amount of pure water at 60°C, and stir for 10 min...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap