Control system for combined harvesters

A combine harvester and control system technology, applied in the field of working condition monitoring system, can solve the problems of easy accidents and inconvenient control, and achieve the effect of reducing accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] As shown in the figure, the specific implementation method is as follows:

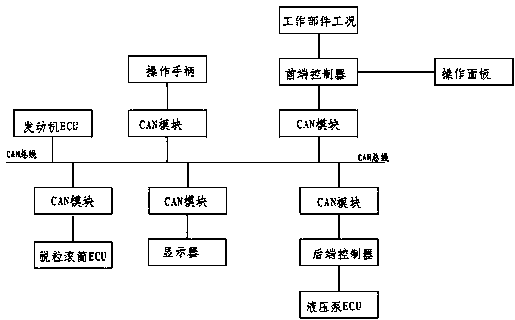

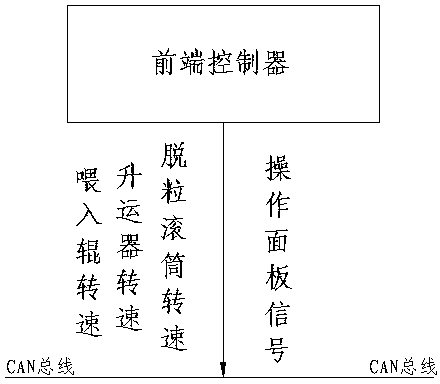

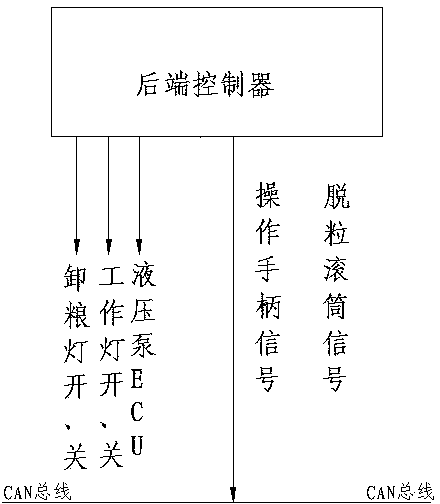

[0020] A control system for a combine harvester. The combine harvester uses an engine as a power source, and a hydraulic pump drives the advance of the combine harvester and the operation of the threshing drum and the harvesting working parts. The control system includes a control system for monitoring the engine The engine ECU, the hydraulic pump ECU used to monitor the hydraulic pump and the threshing drum ECU used to detect the working condition of the threshing drum, the control system is also provided with a front-end controller for receiving the working condition information of the harvesting working parts, for Control the back-end controller of the hydraulic pump ECU, the display for displaying operating parameters and status, and the operating handle for manually controlling the advance of the combine harvester and the operation of the harvesting working parts. The front-end controller, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com