A kind of whole grain noodles and production method thereof

A production method and whole grain technology, which are applied to whole grain noodles and their production, and the fields of noodles and their production, can solve problems such as no production of noodles, and achieve the effects of increasing content, improving physiological activity and comprehensive nutritional composition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Proportion: 60kg of wheat flour, 40kg of fresh waxy corn kernels, 2kg of edible salt.

[0029] production method:

[0030] a. Clean the fresh fresh waxy corn grains;

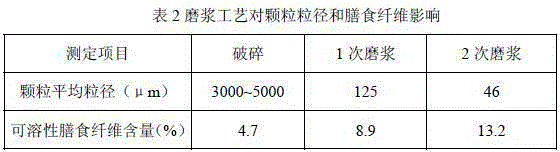

[0031] b. breaking the fresh waxy corn grains into a slurry containing fine particles with a small crusher;

[0032] c. Introduce the slurry obtained in step b into the sedimentation tank, add 120kg of water, add 12g of vitamin C, stir and mix evenly, let stand for 30min, and remove the remaining filaments;

[0033] d. After stirring the product obtained in step c evenly, filter to remove large particles of impurities, and heat up to 45°C;

[0034] e. Send the product obtained in step d into a colloid mill for pulping. The number of pulping times is 2, and the temperature of the slurry is kept at 45°C. The grinding gap is 10μm, and finally the fineness is below 50μm;

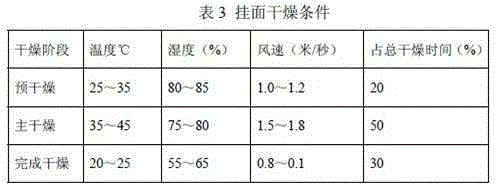

[0035] f. Weigh special noodle powder and edible salt according to the above parts by weight, add the slurry obtained in step e and mi...

Embodiment 2

[0037] Proportion: 70kg of wheat flour, 30kg of fresh waxy corn kernels, 2.5kg of edible salt.

[0038] production method:

[0039] a. Clean the fresh fresh waxy corn grains;

[0040] b. breaking the fresh waxy corn grains into a slurry containing fine particles with a small crusher;

[0041] c. Introduce the product obtained in step b into the sedimentation tank, add 90kg of water, add 10g of vitamin C, stir and mix evenly, let stand for 30min, and remove the remaining filaments;

[0042] d. After stirring the product obtained in step c evenly, filter to remove large particles of impurities, and heat up to 45°C;

[0043] e. Send the product obtained in step d into a colloid mill for pulping. The number of pulping times is 2, and the temperature of the slurry is kept at 45°C. The grinding gap is 10μm, and finally the fineness is below 50μm;

[0044] f. Weigh the special powder for noodles and edible salt according to the above parts by weight, add the slurry obtained in st...

Embodiment 3

[0047] Proportion: 80kg of wheat flour, 20kg of fresh waxy corn kernels, 2kg of edible salt.

[0048] a. thawing the quick-frozen fresh waxy corn kernels;

[0049] b. breaking the fresh waxy corn grains into a slurry containing fine particles with a small crusher;

[0050] c. Introduce the slurry obtained in step b into the sedimentation tank, add 60kg of water and 8g of vitamin C, stir and mix evenly, let stand for 30min, and remove the remaining filaments;

[0051] d. After stirring the product obtained in step c evenly, filter to remove large particles of impurities, and heat up to 45°C;

[0052] e. Send the product obtained in step d into a colloid mill for pulping. The number of pulping times is 2, and the temperature of the slurry is kept at 45°C. The gap between the grinding teeth is 10μm, and finally the fineness can reach below 50μm;

[0053] f. Take noodle special powder and edible salt according to the above weight parts, add the slurry obtained in step e and mix e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com