An extrusion coating machine

A coating machine and extrusion technology, which is applied to the device for coating liquid on the surface, coating, etc., can solve problems such as delamination, achieve the effect of improving coating accuracy and solving delamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

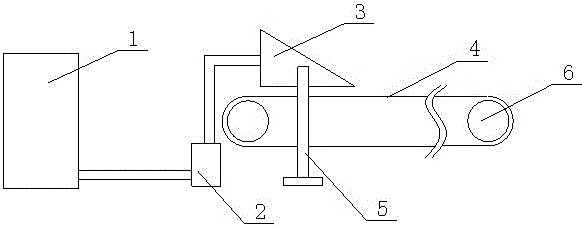

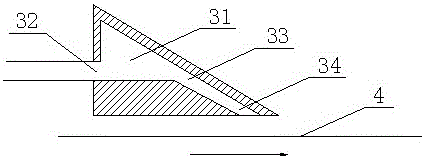

[0021] like figure 1 , 2 As shown, the extrusion coating machine of this embodiment includes a storage tank 1, a screw pump 2, a coating head 3, a control unit and a substrate conveyor belt 4, and the coating head 3 passes through a height-adjustable bracket 5 Arranged above the substrate conveyor belt 4, the coating head 3 is provided with a coating chamber 31, the coating chamber 31 is provided with a feed port 32 and a discharge port 33, and the discharge port 33 is arranged at the top of the coating chamber 31 At the bottom, a pressure sensor is installed in the coating chamber 31; the substrate conveyor belt 4 is driven by a motor 6; the feed port 32 of the storage tank 1, the pump body and the coating chamber 31 is connected in sequence through pipelines, and the The pressure sensor, the screw pump 2, and the motor 6 are connected to the control unit (the control unit and the pressure sensor are not shown in the figure).

[0022] Further, the bottom surface of the feed...

Embodiment 2

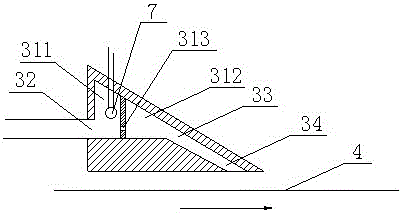

[0027] like image 3 As shown, different from Embodiment 1, in this embodiment, the coating chamber of the coating head 3 is composed of a discharge chamber 312 and a feed chamber 311, and the feed port 32 is arranged at the end of the feed chamber 311. On the chamber wall, the discharge port 33 is arranged at the bottom of the discharge chamber 312; the discharge chamber 312 and the feed chamber 311 are communicated by several feed conduits 313, and the sum of the cross-sectional areas of the feed conduits 313 is smaller than the The cross-sectional area of the feeding port 32 , the pressure sensor 7 is disposed in the feeding cavity 311 .

[0028] The paint enters the feed chamber 311 from the feed port 32 at first. Since the sum of the cross-sectional areas of the feed conduits 313 is less than the cross-sectional area of the feed port 32, the paint will gradually fill the feed chamber 311, making the feed chamber 311 The pressure of the pump body is basically the same...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com