Processing method of steel structure conveying rack for rapid object truck loading

A processing method and steel structure technology, applied in the direction of metal processing equipment, auxiliary devices, manufacturing tools, etc., can solve the problems of reducing processing efficiency, potential safety hazards, large volume, etc., to ensure processing quality, improve processing efficiency, and simple and convenient operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with examples.

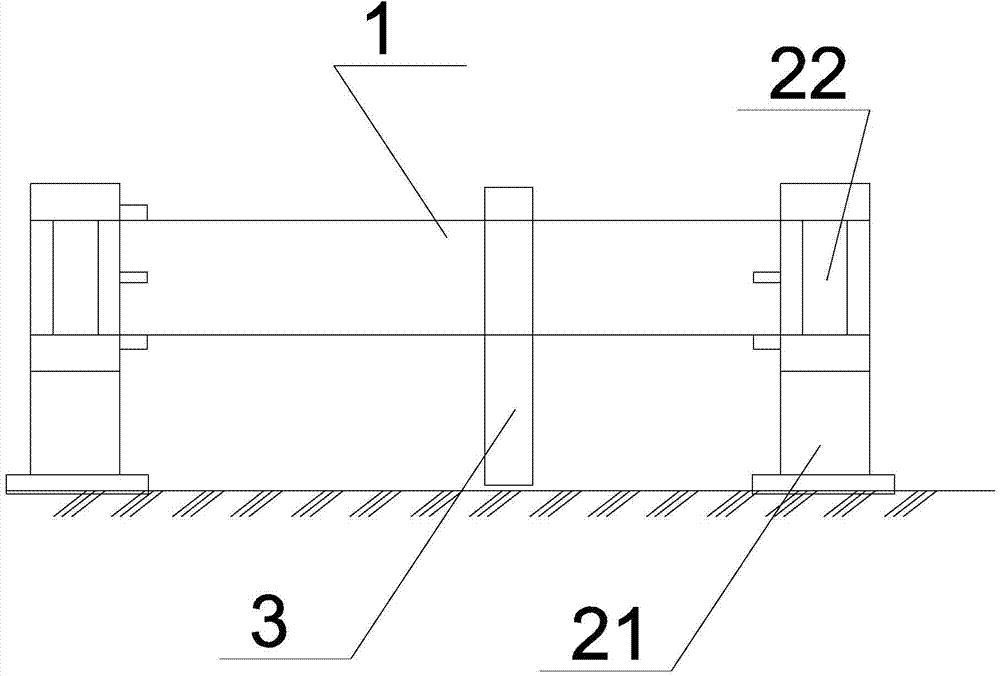

[0017] see figure 1 , will now describe in detail the processing method of the steel structure conveying platform according to the exemplary embodiment of the present invention, mainly including the following steps:

[0018] Step 1: set up an assembled tire frame 21 for support, and install an automatic turntable 22 on the top of the assembled tire frame 21;

[0019] Step 2: Place the main workpiece 1 of the steel structure conveyor table between the two assembled tire frames 21, and fix the two ends of the main workpiece 1 on the automatic turntable 22;

[0020] Step 3: Overall assembly of the main workpiece 1;

[0021] Step 4: welding and fixing the assembled main workpiece 1 by the welding machine 3, and performing front and back welding through the rotation cooperation of the two automatic turntables 22 at the same time;

[0022] Step 5: Check whether the welding quality is qual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com