Automatic pressing plate with guide pin

A pressing plate and automatic technology, applied in the field of mechanical processing, can solve the problems of high cost and complex structure, and achieve the effect of low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

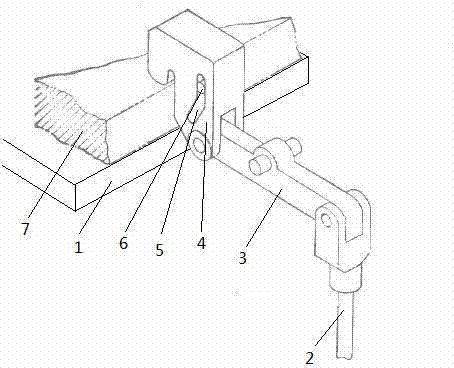

[0010] Such as figure 1 The shown automatic pressing plate with guide pins includes a base 1, a force applying rod 2, a pressing arm 3, a pressing plate 4, a guide hole 5 set on the pressing plate, a guide pin 6 set in the guiding hole and a workpiece 7 , a pressure sensor and a positioning groove (not shown in the figure) are provided on the upper surface of the base. It has a degree of freedom in the vertical direction, one end of the pressing arm is connected to the top of the force applying rod, the middle part of the pressing arm is hinged, and the other end of the pressing arm is connected to the bottom of the pressing plate.

[0011] The pressure sensor is used to detect the clamping force of the pressure plate to avoid damage to the workpiece due to excessive pressure during the clamping process. The positioning groove is used to p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap