3D (Three-dimensional) high-density product printing mode

A 3D printing and 3D printer technology, applied in the field of 3D printing, can solve the problems of inability to produce and control the density of homogeneous materials for processing, and achieve the effect of narrowing the molecular gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

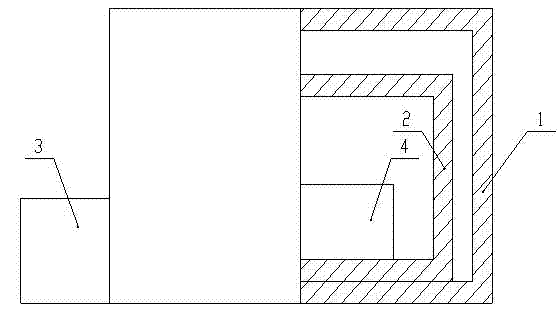

[0010] Such as figure 1 Shown: a method of 3D printing high-density products, which is composed of a 3D printer bed 2, a high-pressure chamber 1 and a high-pressure pump 3.

[0011] The 3D printer bed 2 is installed in the high-pressure chamber 1, and the compressed air is delivered to the high-pressure chamber 1 by the high-pressure pump 3. When the 3D printer bed 2 is printing, the strong pressure in the high-pressure chamber 1 compresses the printed workpiece to reduce the molecular gap of the homogeneous material. Density increases.

[0012] The 3D printer bed 2 can also be installed in the high-pressure chamber 1 to mainly realize the printing of working parts, and other parts are left outside the high-pressure chamber, which can reduce damage to other parts of the 3D printer bed 2 by high pressure. The high-pressure chamber 1 can be provided with multiple or single high-pressure inlets and outlets, and the high-pressure pump 3 can be installed in the high-pressure cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com