Polyaspartic acid ester, preparation method thereof and application of polyaspartic acid ester in sealing coating

An aspartate and sealing coating technology, applied in polyurea/polyurethane coatings, fire-retardant coatings, coatings, etc., can solve the problems of decreased flame retardancy, poor sealing performance of coatings, radioactive leakage, etc., and achieve air tightness High performance, increased air leakage resistance, strong flame propagation resistance and air tightness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

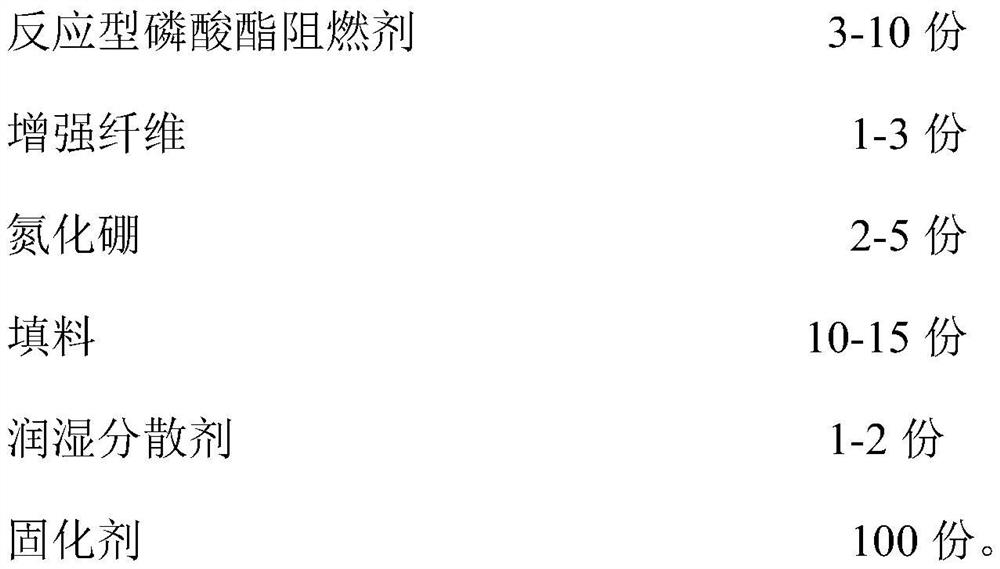

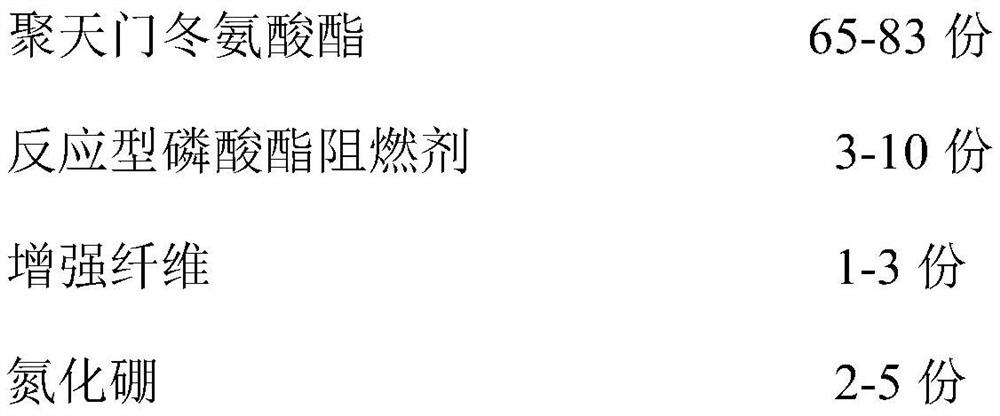

Method used

Image

Examples

Embodiment 1

[0039] This example provides a kind of polyaspartate, its raw material includes 2mol 2,4-diamino-3,5-dimethylthiotoluene, 1mol 3,3'-dimethyl-4,4'- Diamino-dicyclohexylmethane and 1.5mol diethyl maleate

[0040] The specific preparation method is as follows:

[0041] 1) Under nitrogen protection, add 2,4-diamino-3,5-dimethylthiotoluene and 3,3'-dimethyl-4,4'-diamino-dicyclohexylmethane into the Speed-adjusting agitator, reflux condensation dehydration equipment, four-necked bottle of thermometer;

[0042] 2) Slowly add diethyl maleate dropwise at room temperature, and control the temperature during the addition process to not be higher than 60°C. The measured diethyl maleate is all dropped in within 2 hours;

[0043] 3) Continue to react at 60°C for 4 hours, then heat to 80°C, and then continue to react for 6 hours, track the progress of the addition reaction during the reaction, and stop when the measured unsaturation value is 6.5-6.8mg / g reaction;

[0044] 4) Distill at ...

Embodiment 2

[0047] This example provides a kind of polyaspartate, its raw material includes 2mol 2,4-diamino-3,5-dimethylthiotoluene, 1mol 3,3'-dimethyl-4,4'- Diamino-dicyclohexylmethane and 1.5mol diethyl maleate

[0048] The specific preparation method is as follows:

[0049] 1) Under nitrogen protection, add 2,4-diamino-3,5-dimethylthiotoluene and 3,3'-dimethyl-4,4'-diamino-dicyclohexylmethane into the Speed-adjusting agitator, reflux condensation dehydration equipment, four-necked bottle of thermometer;

[0050] 2) Slowly add diethyl maleate dropwise at room temperature, and control the temperature during the addition process to not be higher than 60°C. The measured diethyl maleate is all dropped in within 2 hours;

[0051] 3) Continue to react at 60°C for 4 hours, then heat to 80°C, and then continue to react for 6 hours, track the progress of the addition reaction during the reaction, and stop when the measured unsaturation value is 6.5-6.8mg / g reaction;

[0052] 4) Distill at ...

Embodiment 3

[0055] This example provides a kind of polyaspartate, its raw material includes 2mol 2,4-diamino-3,5-dimethylthiotoluene, 1mol 3,3'-dimethyl-4,4'- Diamino-dicyclohexylmethane and 1.5 mol of diethyl maleate.

[0056] The specific preparation method is as follows:

[0057] 1) Under nitrogen protection, add 2,4-diamino-3,5-dimethylthiotoluene and 3,3'-dimethyl-4,4'-diamino-dicyclohexylmethane into the Speed-adjusting agitator, reflux condensation dehydration equipment, four-necked bottle of thermometer;

[0058] 2) Slowly add diethyl maleate dropwise at room temperature, and control the temperature during the addition process to not be higher than 60°C. The measured diethyl maleate is all dropped in within 2 hours;

[0059] 3) Continue to react at 60°C for 4 hours, then heat to 80°C, and then continue to react for 6 hours, track the progress of the addition reaction during the reaction, and stop when the measured unsaturation value is 6.5-6.8mg / g reaction;

[0060] 4) Distil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com