Tire balance point aligning method and device

A tire balancing, point-to-point technology, applied to wheel fixing devices, measuring devices, wheel assembly and disassembly equipment, etc. The effect of easy operation, lower rework rate and lower cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

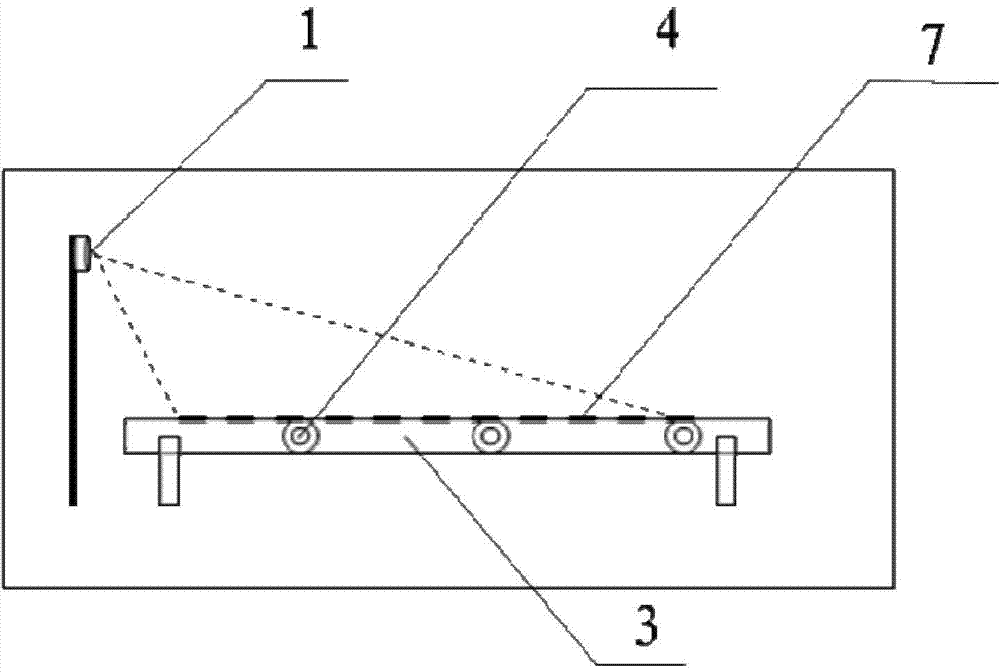

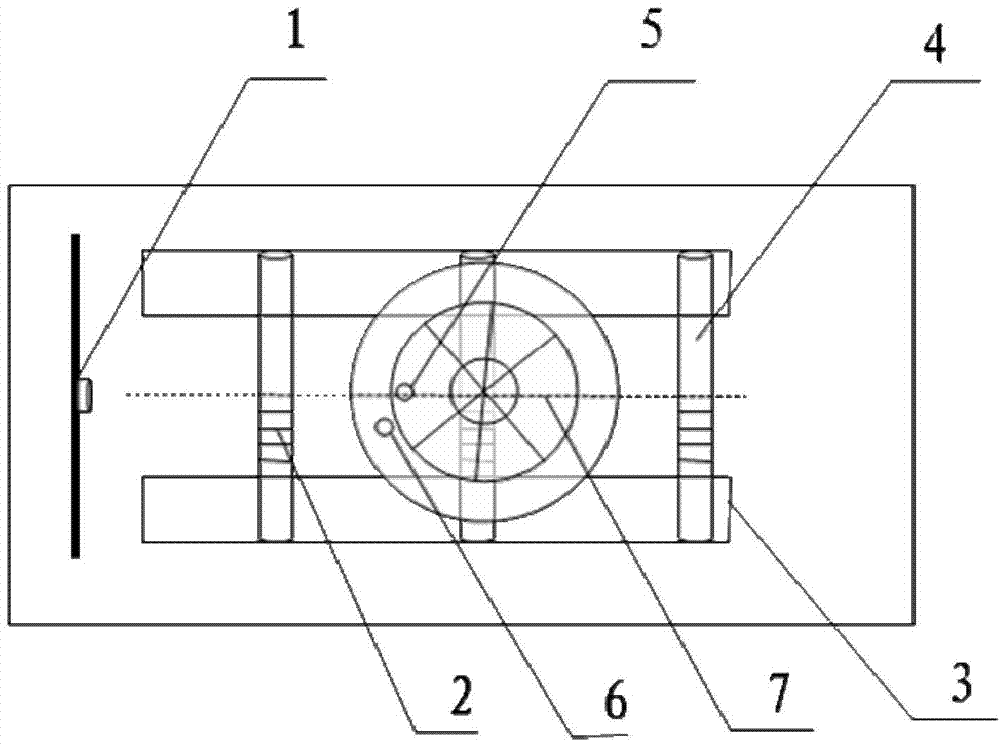

[0027] Such as Figure 1-2 As shown, the embodiment of the present invention provides a tire balance point-to-point method, which is applied in the production process of automobile tire lines, and the method is carried out according to the following steps,

[0028] Step 1: Determine the on-site reference object, and fix the placement position of the wheel hub through the reference object, so that the center point 5 of the wheel hub is placed in the middle of the rolling bed 3, as a reference line for aligning the light point 6 of the tire;

[0029] Specifically, the step 1 is to set an infrared spotlight 1 at the end of the rolling bed 3, and use the rays 7 of the infrared spotlight 1 to fix the position of the hub focus 5, so that the The ray 7 is aligned with the hub focal point 5, that is, when a person places the hub on the rolling bed 3, the hub focal point 5 must face the ray 7 of the infrared spotlight 1;

[0030] Specifically, the infrared spotlight 1 is positioned at...

Embodiment 2

[0040] see Figure 1-2 , the present invention provides a device applied to the tire balance point-to-point method described in Embodiment 1, installed on the rolling bed 3, the device includes a base bracket and an infrared spotlight 1, and the base bracket is fixed on the The end of the rolling bed 3 is on the ground, and the infrared spotlight 1 is fixed at the middle position of the base bracket.

[0041] In the embodiment of the present invention, by setting a reference object, the reference object is aligned with the position of the hub point 5 on the rolling bed 3, and then the position of the tire light point 6 is correctly adjusted according to the offset size measured on site, so that the tire and the wheel hub pass through After the press-fitting machine, the key point 5 of the wheel hub will correspond to the position of the light point 6 of the tire, which solves the problem of out-of-tolerance tire alignment, ensures the qualified rate of tire production, reduces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com