Convenient water-saving all-composite nano-filtration and reverse osmosis water purifier

A water-saving, reverse osmosis technology, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as waste of water resources, loose structure, and large dimensions. Achieve the effect of convenient installation, convenient installation and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

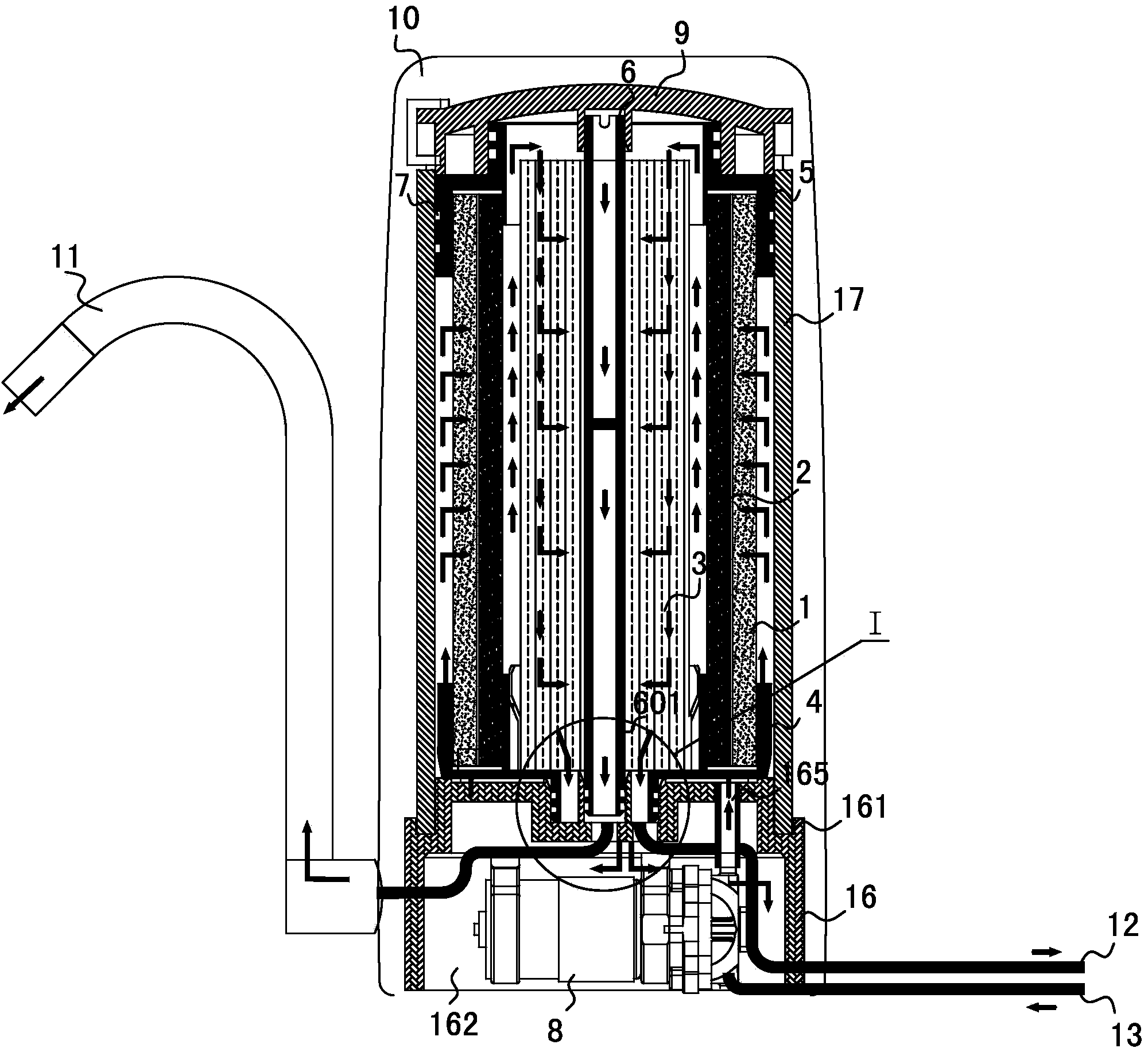

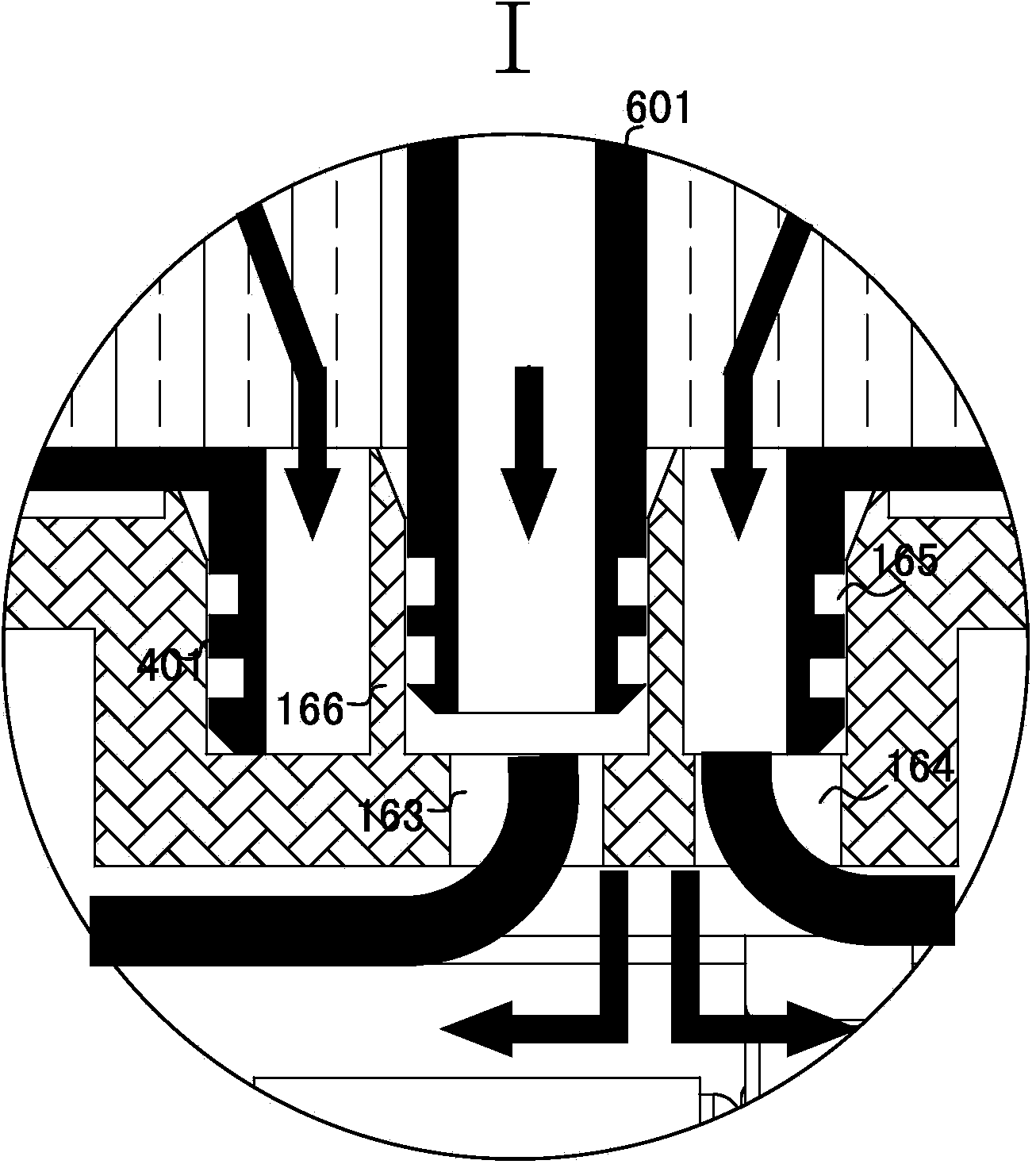

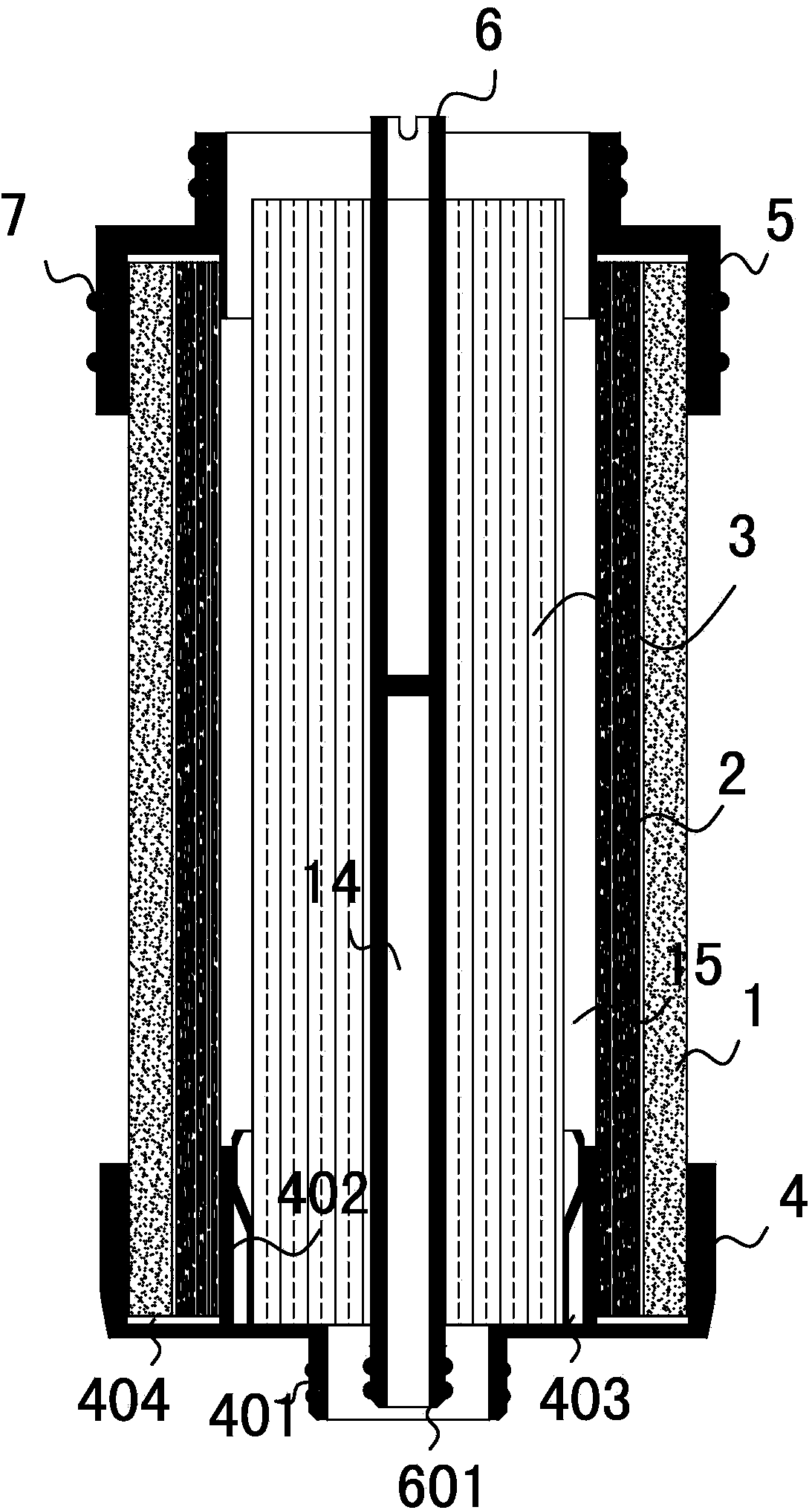

[0010] Such as figure 1 As shown, the convenient water-saving full-composite nanofiltration and reverse osmosis water purifier includes a housing 10 , a filter element and a micro booster pump 8 . The housing 10 is provided with a water purification spout 11, and the filter element and the micro booster pump 8 are arranged in the housing 10. In order to achieve the same filtering effect as that of the existing household water supply machine or water purifier, the structure is compact , the filter element is a composite filter element, the composite filter element is a columnar, radially multi-layer composite structure, the center of the composite filter element is axially provided with a water outlet chamber 14, and the composite filter element is respectively sedimentation filter element layer 1, Activated carbon filter layer 2 and high-capacity nanofiltration 3 or reverse osmosis filter layer (filter capacity not less than 400 gallons / 24h or 1.2L / min), thus simplifying the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com