Preparation method for gamma-TiAl alloy small fully-lamellar tissue

A full-lamellar and microstructure technology, which is applied in the field of fine full-lamellar microstructure preparation of γ-TiAl alloys, can solve the problems of low plasticity of γ-TiAl alloy parts at room temperature, and achieve the effects of avoiding adverse effects, reducing requirements, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

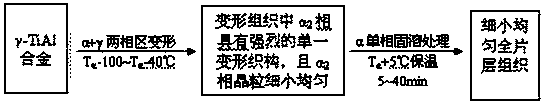

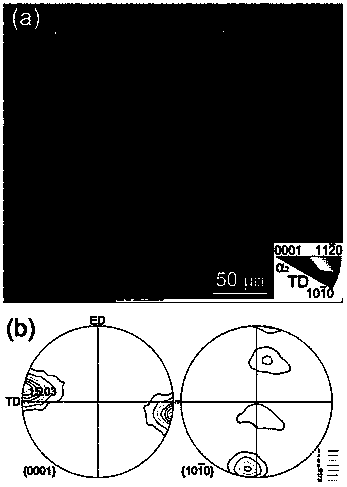

[0032] Such as figure 1 As shown, the process of preparing the fine full-lamellar structure of γ-TiAl alloy is as follows: ① Preparation of γ-TiAl alloy; ② γ-TiAl alloy in the α+γ two-phase region, T α -100~T α Deformation in the -40°C temperature range to obtain α 2 The phase has a strong single deformation texture, and α 2 The phase grains are fine and uniform; ③The deformed structure is solid solution treated in the α single-phase region, and the solid solution time does not exceed the critical time for the texture to effectively inhibit the growth of α grains. α Incubate at +5°C for 5-40 minutes to obtain a fine and uniform full-lamellar tissue.

[0033] In the present invention, T α Represents the α phase transition temperature, which varies with the Al content. When the Al content is 47%, T α It is 1340°C. In terms of atomic percentage, the composition of γ-TiAl alloy is: Al43~48%; B0~0.15%; Nb2~8%; Cr1.5~3%; Ti balance. α in deformed tissue 2 The phase grain siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com