Spinning safety device

A safety device and yarn technology, applied in textiles and papermaking, etc., can solve the problems of no alarm device, labor-intensive, easy-to-break yarn, etc., and achieve the effect of ensuring production safety and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

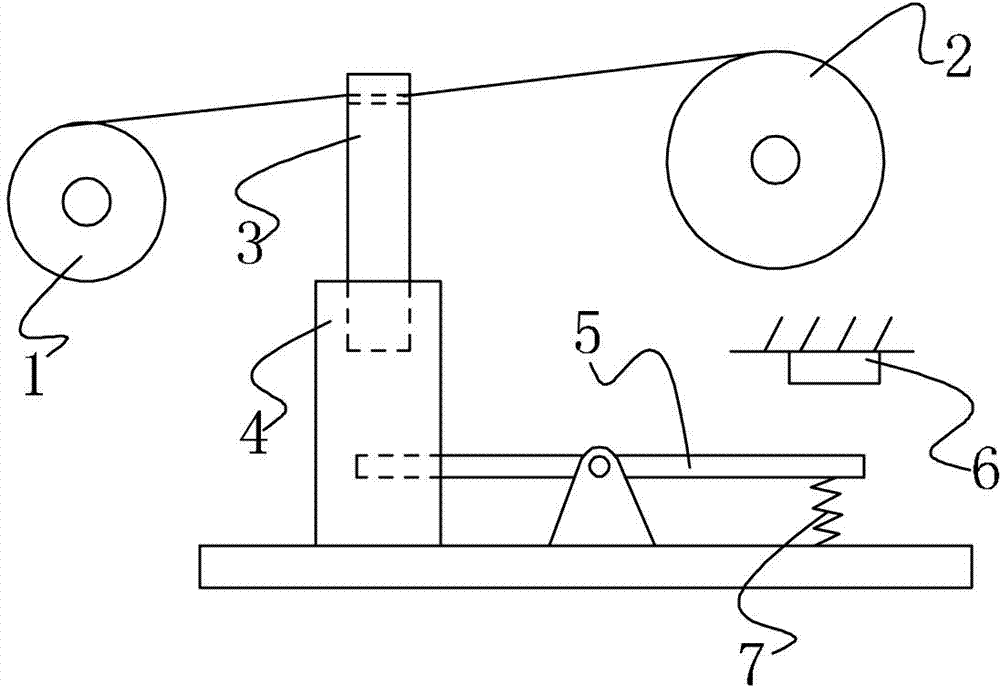

[0010] like figure 1 Shown: Spinning safety device, set between reel 1 and bobbin 2, and yarn is stretched between reel 1 and bobbin 2. The spinning safety device includes a frame, a gravity block 3, and a slide hole is opened on the gravity block 3, and the yarn is passed into the gravity block 3 along the slide hole. Gravity block 3 is suspended.

[0011] A vertical chute 4 is fixed on the frame, and the lower end of the gravity block 3 is inserted in the chute 4, and the lower end of the chute 4 is vertically provided with a gap. The rocker 5 is hinged on the frame, and the hinge point is located on the same straight line as the notch of the chute 4 . The left end of rocker 5 is inserted in the chute 4 along the gap, and the right end of rocker 5 is opposite to the power contact 6. When the right end of rocker 5 is upturned, it is inserted in the power contact 6 to cut off the power supply. The right end of the seesaw 5 is equipped with a spring 7 connected to the frame,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com