Woolen yarn strand, woolen yarn made of same by means of twisting and method for manufacturing woolen yarn

A wool and plush technology, applied in the field of wool and wool preparation, can solve the problems of affecting the beauty of knitted products, easy hair loss of wool, time-consuming and laborious hair, and achieve the effect of avoiding hair loss, improving wearing life, and connecting firmly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

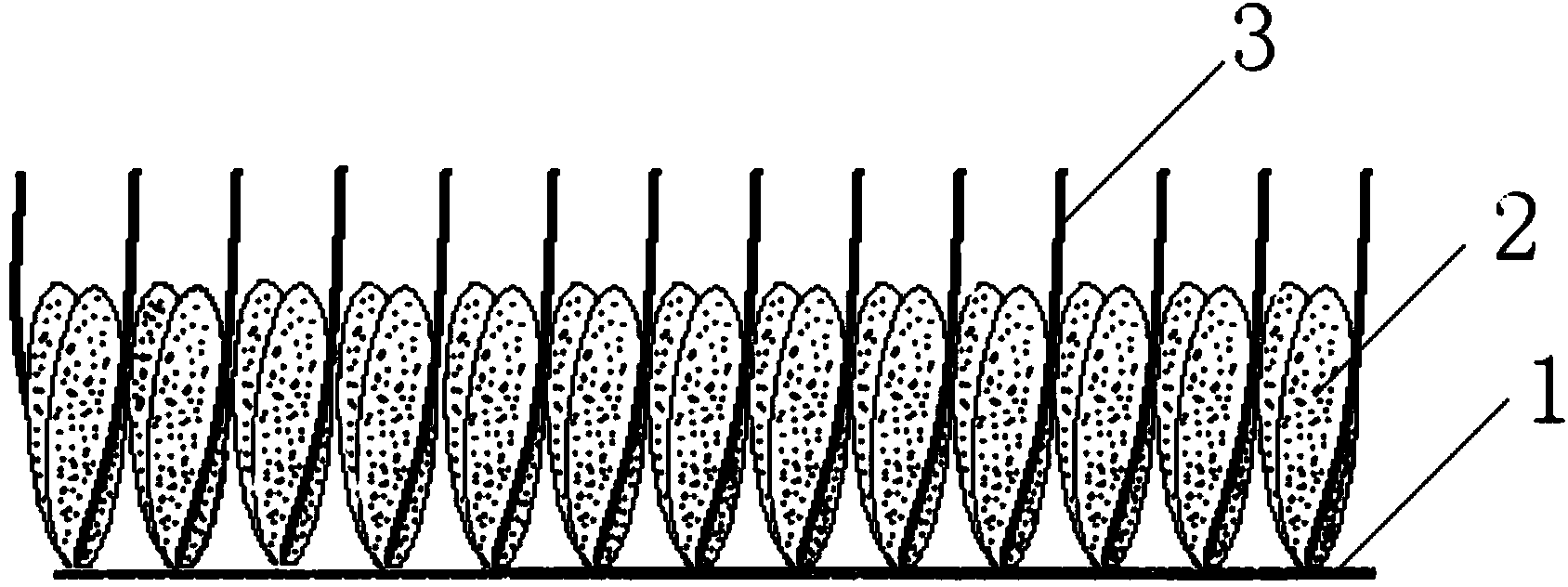

[0022] Referring to Fig. 1, the present embodiment provides a woolen strand, comprising a strip-shaped substrate 1, on which a plurality of plush tufts 2 are tightly arranged along the length direction of the strip-shaped substrate 1, in each plush tuft 2 Both are provided with bright silk 3, the length of the bright silk 3 is greater than the length of the plush tuft 2; the strip-shaped matrix 1 is a multi-strand braided strip-shaped matrix; the middle part of the plush tuft 2 and the bright silk 3 It is connected with the elongated base 1 by weaving into the elongated base 1 .

[0023] The above-mentioned wool strands, because the middle part of the plush tufts 2 and the bright silk 3 are connected to the elongated base 1 by weaving into the elongated base 1, therefore, the connection is relatively firm, and after many times of wearing and washing, the wool Both the tufts 2 and the bright silk 3 are not easy to fall off, which improves the wearing life of the clothes, and co...

Embodiment 2

[0030] This embodiment provides a woolen yarn, which is twisted from multiple strands of the woolen yarn described in Embodiment 1, and the twisting method is S twisting.

[0031] In this embodiment, optionally, the woolen yarn is twisted from two woolen strands described in Embodiment 1, and the twisting method is S twisting.

[0032] Through experiments, when the woolen yarn in this embodiment is woven into clothes, the plush tufts and bright silk are not easy to fall off, which improves the wearing life of the clothes, and compared with the traditional woolen clothes, it avoids the work of cleaning the shedding , and due to the addition of bright silk, it has the advantage of high brightness. In addition, because there are multiple plush tufts closely arranged along the length of the strip-shaped substrate, when weaving errors, the appearance caused by errors is not obvious, and it is almost impossible. Shows a change in appearance, thus reducing reject rates.

Embodiment 3

[0034] This embodiment provides a kind of preparation method of woolen yarn, comprises the following steps:

[0035] S10, preparing polyester bright silk, plush tufts and matrix weaving strands;

[0036] S20, knitting polyester bright silk, plush tufts and base knitting strands together on a crochet machine to form wool strands;

[0037] S30. Twisting a plurality of strands of woolen yarn into woolen yarn.

[0038] The twisting described in step S30 preferably adopts S twist.

[0039] In step S10, the method for preparing the polyester bright yarn, plush tufts and matrix braided strands can be the method commonly used in the prior art, and will not be repeated here.

[0040] The woolen yarn prepared by the woolen yarn preparation method described in this embodiment is connected to the strip-shaped matrix by weaving the middle part of the plush tufts and bright silk into the strip-shaped matrix, so the connection is relatively firm. After many times of wearing and washing, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap