Wool milling, rubbing and winding integrated device

A technology of kneading device and winding device, which is applied in the fields of winding integrated device, kneading, and wool milling, which can solve the problems of carpet shedding and other problems, and achieve the effect of smooth surface, reduced hair shedding rate, and tight tissue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

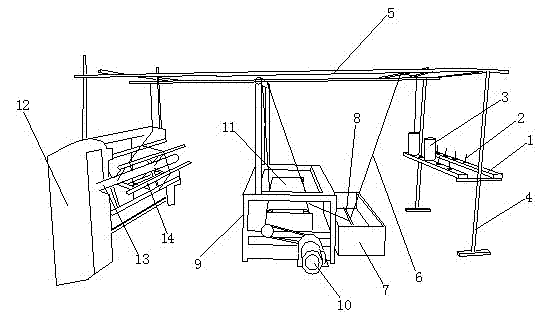

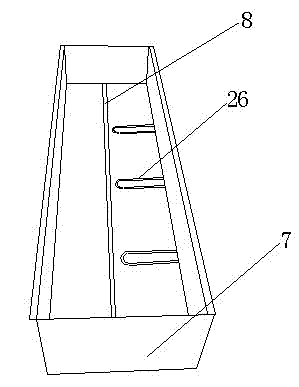

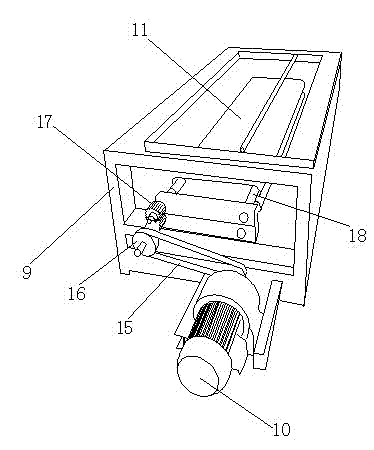

[0019] Such as Figure 1 to Figure 4 As shown in the present invention, a wool fulling, kneading, and winding integrated device, the two ends of the device are respectively provided with a raw material frame 1 and a winding device 12, and a rubbing device 9 is arranged between the raw material frame 1 and the winding device 12. , a milling pool 7 is arranged between the rubbing device 9 and the raw material rack 1, and the raw material rack 1, the winding device 12, the rubbing device 9 and the milling pool 7 are arranged in parallel with each other, and the raw material rack 1, the winding device 12 and the kneading pool Side brackets 4 are arranged on the device 9 respectively, and the side brackets 4 are respectively connected with the top brackets 5 . A number of bobbins 2 are arranged on the raw material frame 1, and a wool yarn bobbin 3 is arranged on the bobb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com