Construction method and combined packaging method of railway rail fastener

A construction method and technology of fasteners, which are applied in the field of construction methods and combined packaging of railway rail fasteners, can solve the problems of low construction efficiency and inconvenient construction, and achieve the effects of good positioning, beautiful appearance and good economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

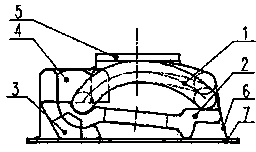

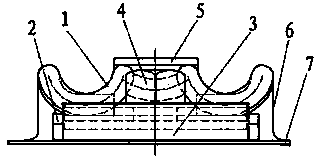

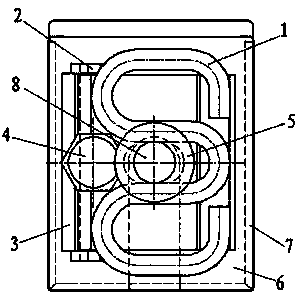

[0037] A kind of combined packing of the railway rail fastener that realizes above-mentioned method, as Figure 8 , including elastic strip 1, gauge baffle 2, baffle seat 3, nut 4 and flat washer 5, characterized in that the elastic strip 1, gauge baffle 2, baffle seat 3, nut 4 and flat washer 5 are according to the actual engineering The combined positions are combined together, and the nut 4 is placed in the middle position of the elastic bar 1 on the upper part of the baffle seat 3 to form a whole assembly; the heat shrinkable plastic film 6 is wrapped outside the whole assembly, and the heat shrinkable plastic film 6 will be assembled The railway rail fastener components are fixed by heat shrinking. Elastic bar 1, gauge baffle 2, baffle seat 3, nut 4, and flat washer 5 are combined and installed according to the actual project, and the whole package is fixed through the heat shrinkage of the thinner plastic film 6, wherein the nut 4 is placed on the baffle seat 3 The uppe...

Embodiment 2

[0039] A kind of combined packing of the railway rail fastener that realizes above-mentioned method, as Figure 1-7 , including elastic strip 1, gauge baffle 2, baffle seat 3, nut 4 and flat washer 5, characterized in that the elastic strip 1, gauge baffle 2, baffle seat 3, nut 4 and flat washer 5 are according to the actual engineering The combined positions are combined together, and the nut 4 is placed in the middle of the spring bar 1 on the upper part of the baffle seat 3 to form an integral assembly; the entire assembly is wrapped with plastic packaging materials. The plastic packaging material is a heat-shrinkable plastic film 6, and the heat-shrinkable plastic film 6 fixes the combined railway rail fastener parts through heat shrinkage. A hard base plate 7 is placed under the assembled railway rail fastener parts, and the hard base plate 7 is used as the bottom support of the railway rail fastener assembly. When the plastic film is heat-shrinkable 6 and packaged, a bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com