Liquefaction resistance foundation stabilization method by grate hooping

A foundation reinforcement and anti-liquefaction technology, which is applied in basic structure engineering, soil protection, construction, etc., can solve the problems of limited lateral displacement, low overall foundation stiffness, obvious subsidence, inclination, etc., to achieve strong applicability, Eliminate subsidence due to liquefaction of the ground, less impact on the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

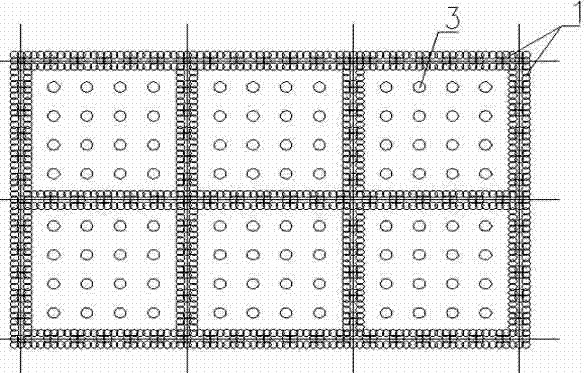

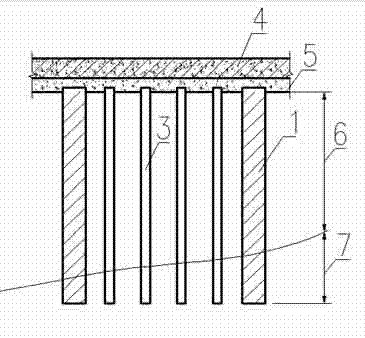

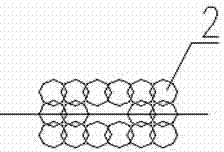

[0048] Embodiment one: see figure 1 , figure 2 , image 3 , the site is located in a gentle slope area, the ground slope is about 12°, and the foundation is a large-scale monolithic foundation 4 (raft foundation). Soil pile wall 1 adopts such as figure 2 The grid structure shown is constructed by cutting and lapping the cement-soil pile 2; the cement-soil pile wall 1 penetrates the liquefied soil layer 6 and extends into the stable soil layer 7 below the liquefaction depth; To improve the bearing capacity of the anti-liquefaction composite foundation and reduce settlement deformation, the vertical reinforcements 3 are commonly arranged in a square; the composite foundation is provided with a 30cm-thick graded sandstone cushion layer 5 .

Embodiment 2

[0049] Embodiment two: see Figure 4 , the foundation is an independent foundation, and the cement-soil pile wall is arranged under the axis of 1 column, which divides the foundation into a closed grid; under the independent foundation, the foundation treatment is carried out according to the conventional method, so that the bearing capacity and settlement deformation of the composite foundation meet the design requirements, and It is integrated with the cement-soil pile wall 1 to improve the overall strength and rigidity of the foundation.

Embodiment 3

[0050] Embodiment three: see Figure 5 , Figure 6 , the foundation is a strip foundation 8, and the cement-soil pile wall 1 is arranged under the strip foundation wall. The cutting and lapping method is adopted to divide the foundation into closed grids; Stone mattress cushion 5.

[0051] A project is a comprehensive building near the Fenhe River in Taiyuan City, with a height of 10 floors and a frame structure. The raft foundation is designed, which requires high bearing capacity of the foundation and is sensitive to settlement deformation. The site is located in a gentle slope area, the ground slope is about 12°, the seismic fortification intensity is 8 degrees, the liquefaction level of the foundation is serious, and the composition and distribution of the foundation soil layer is: the upper part is saturated sandy soil and silt soil, and the silt soil has a strong sense of sand, loose to slightly dense , with a layer thickness of 7.5-10.0m; the lower part is silty clay,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com