Method for mounting drum framework of drum strainer

An installation method and filter screen technology are applied in the fields of construction, building structure, and building material processing, which can solve the problems of high installation difficulty, low safety factor, and low work efficiency, and achieve saving manpower and material resources, easy control, and improved The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

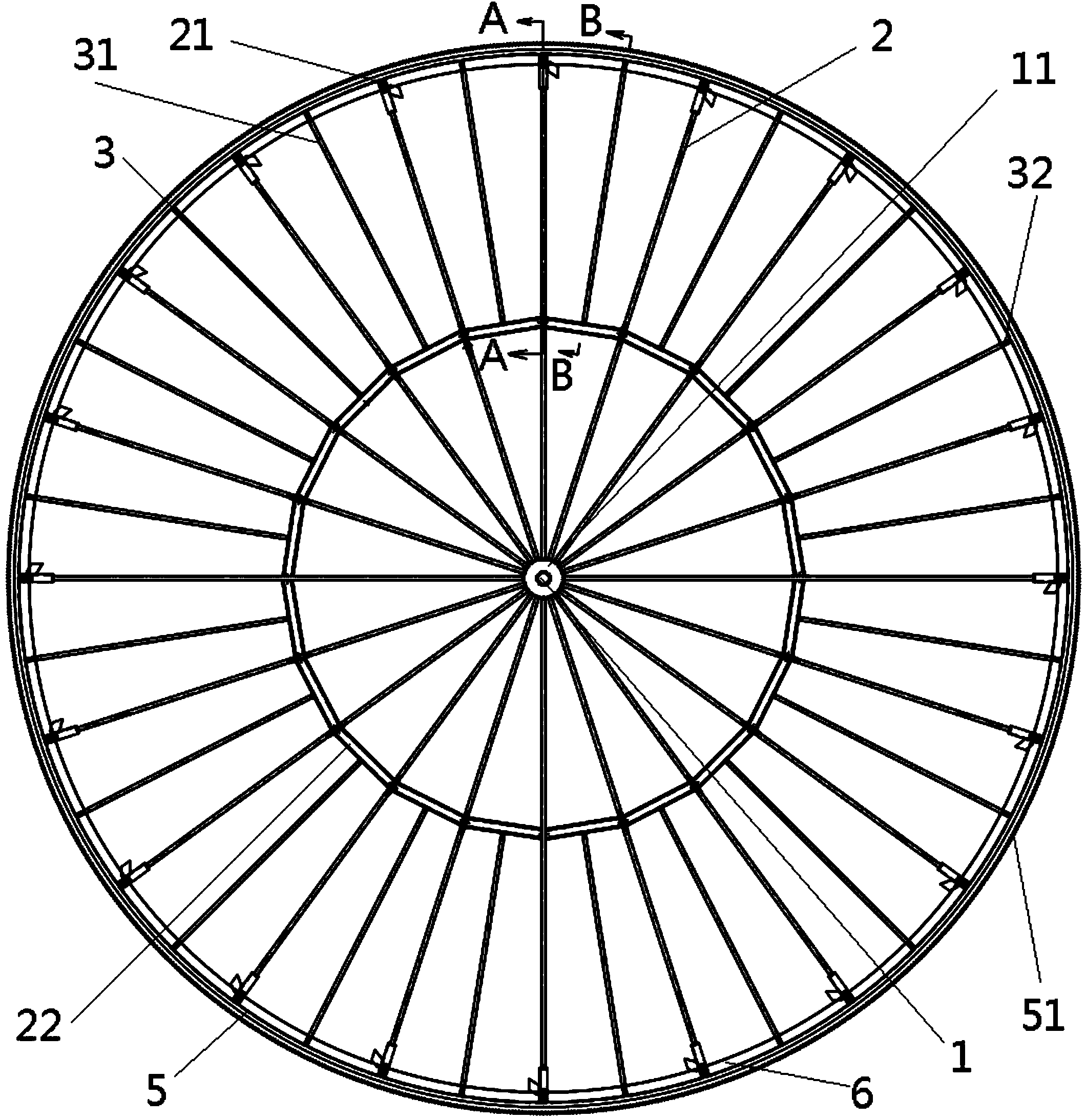

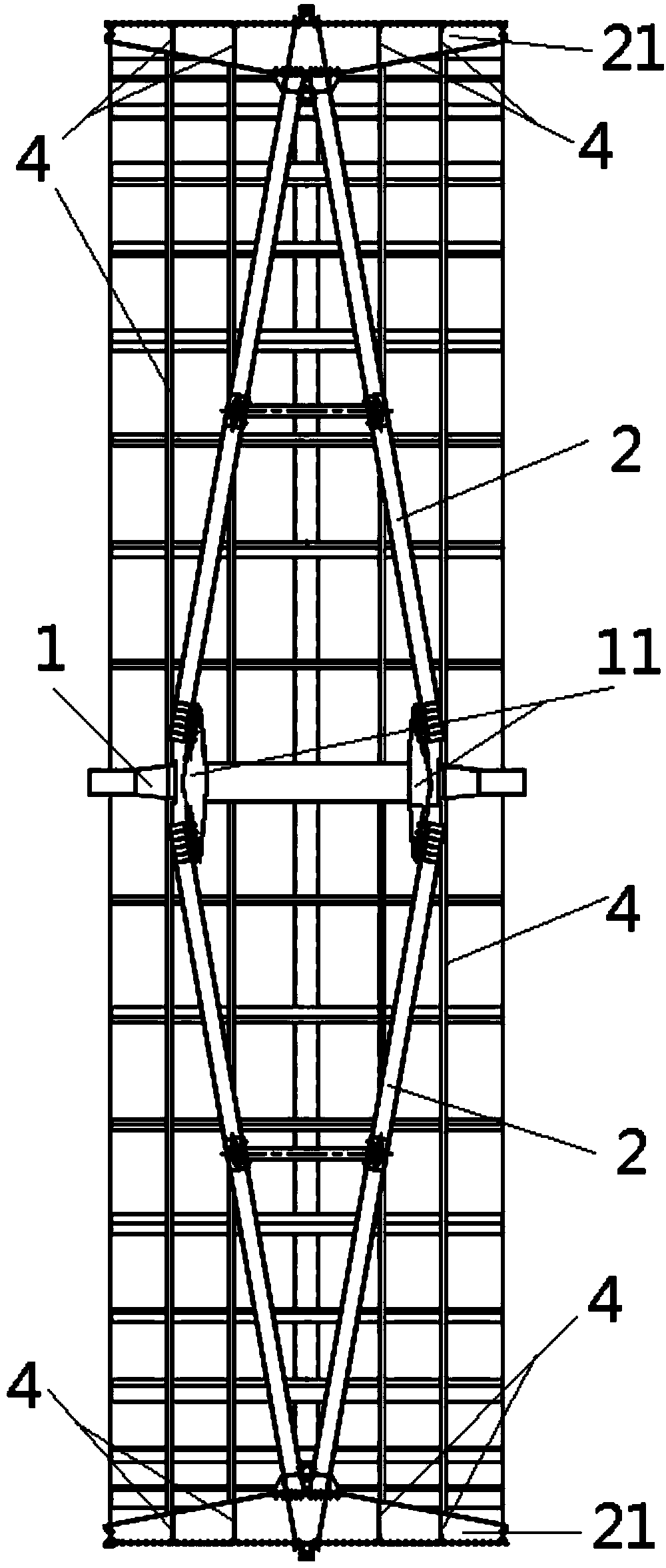

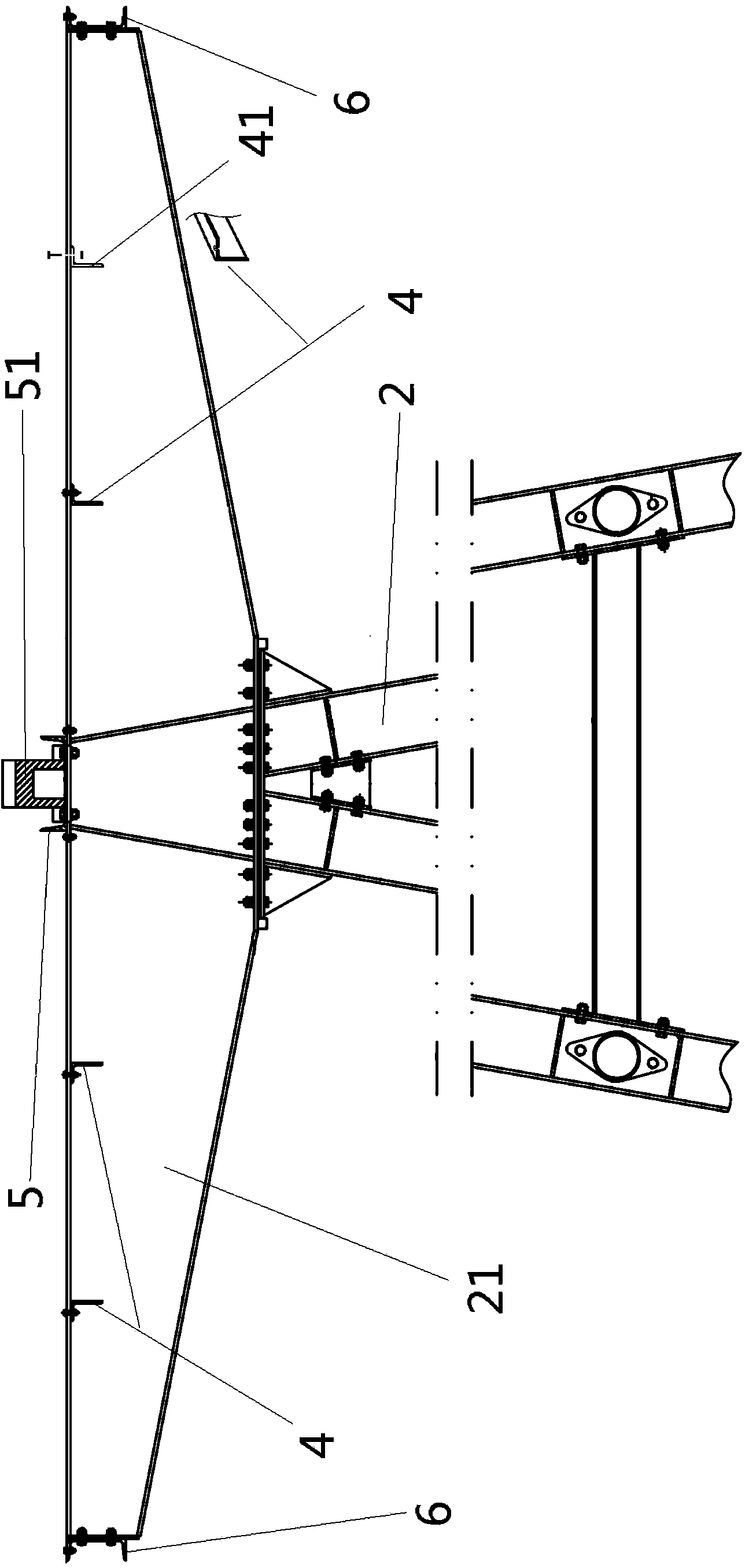

[0023] Such as figure 1 , figure 2 , image 3 as well as Figure 4 Shown, a kind of drum-shaped strainer drum frame installation method, this method comprises the following steps:

[0024] In the first step, all the main spokes 2 are sequentially installed on the hub 11 of the main shaft 1, and two adjacent main spokes 2 are connected by connecting pieces 22; a sub-spoke 31 and a sub-beam 32 are assembled to form a Group the sub-spoke group 3, so that each sub-spoke 31 is fixedly connected with a sub-beam 32;

[0025] In the second step, the main beam 21 is installed on the main spoke directly above the main shaft, and the first main spoke on which the main beam is installed is called the first main spoke, and the main spoke adjacent to the first main spoke is called It is the second main spoke, and so on. Use a hoist (not shown in the figure) to pull the first main spoke, so that the second main spoke rotates to the top of the main shaft 1, and then install the main bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com