Shaped turntable bearing for sewage treatment

A special-shaped turntable and sewage treatment technology, which is applied in the field of machinery, can solve the problems of difficult processing and low service life of special-shaped turntable bearings, and achieve the effects of easy processing, improved service life and reduced costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

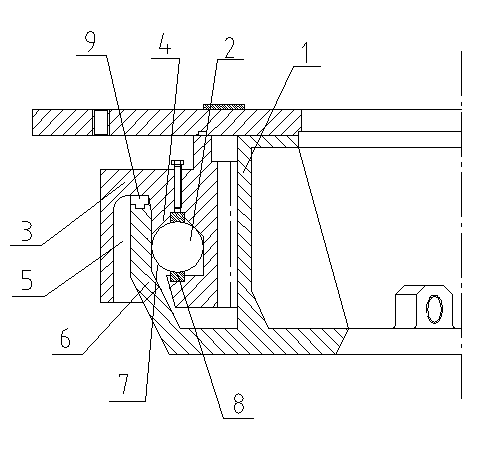

[0011] As shown in the figure, a special-shaped turntable bearing for sewage treatment includes an outer ring 3, an inner ring 1 and steel balls 2 arranged between the inner and outer rings. The outer ring 3 has a built-in space 5 communicating with the outside world. The built-in space 5 is provided with a partition 4, and the partition 4 and the side wall of the built-in space 5 constitute the rolling body space 7 of the steel ball 2, and the upper and lower parts of the rolling body space 7 are correspondingly inlaid with a wear-resistant steel ring 8, and the steel ball 2 Rolling on the wear-resistant steel ring 8, the inner ring 1 has an extension 6, which extends into the built-in space 5 of the outer ring 3 and seals the rolling body space 7.

[0012] The extension part 6 together with the partition plate 4 and the side wall of the built-in space 5 constitute a position-limiting mechanism that limits the deviation of the steel ball 2 .

[0013] One end of the separa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com