Novel preload regulation device for high-speed motorized spindle bearing

A high-speed motorized spindle and adjusting device technology, applied in shafts and bearings, bearing components, mechanical equipment, etc., can solve complex problems, affect bearing performance, change bearing structure, etc., and achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

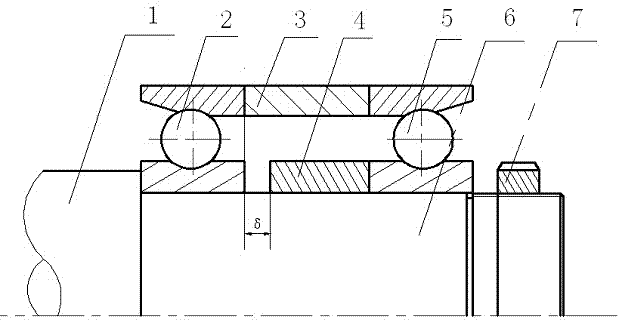

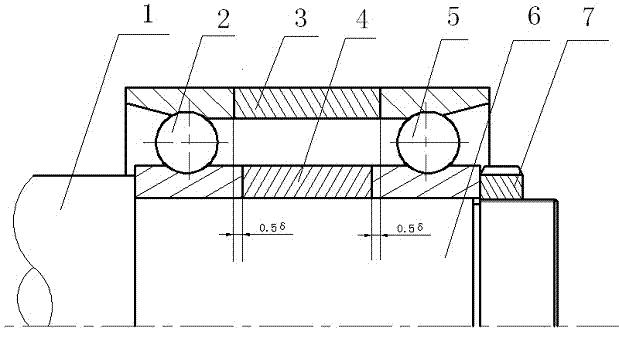

[0019] see figure 1 and figure 2 , the new type of high-speed electric spindle bearing preload adjustment device, including shaft shoulder, front bearing, outer spacer, inner spacer, rear bearing, main shaft and lock nut, the front and rear bearings are separated by inner and outer spacers and set on the main shaft One end is against the shoulder of the shaft, and the other end is locked with a lock nut. It is characterized in that the inner and outer spacers are made of materials with very different linear expansion coefficients, and the linear expansion coefficient of the inner spacer is greater than that of the outer spacer. coefficient, the axial length of the inner spacer is smaller than the outer spacer at room temperature, when the motorized spindle rotates at a high speed, the temperature rises, and the axial elongation of the inner spacer with temperature rise is greater than that of the outer spacer. Make the length difference between the two spacers smaller than t...

Embodiment 2

[0021] Such as figure 1 As shown, the new type of high-speed electric spindle bearing preload adjustment device uses the characteristics of the large difference in the linear expansion coefficients of the inner and outer spacers made of different materials to adjust the preload of the high-speed electric spindle bearing: during the initial installation, due to the external Spacer 3 (if the material is ceramics, the coefficient of linear expansion is 4×10 -6 / °C) the linear expansion coefficient is small, and the inner spacer 4 (if the material is aluminum alloy, the linear expansion coefficient is 24×10 -6 / °C) has a large coefficient of linear expansion. In order to apply pretightening force to the bearing, the length of the outer spacer is greater than that of the inner spacer. At this time, the difference in the axial length of the two rings is δ; as the speed increases, the temperature rises, The axial elongation of the inner spacer ring with temperature rise is larger t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Linear expansion coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com