Modularized combination ceiling lamp

A ceiling lamp, modular technology, applied in lighting and heating equipment, semiconductor devices of light-emitting elements, point light sources, etc., can solve problems such as hidden safety and quality, poor flexibility, copper-clad cracking, etc., to achieve convenient maintenance, Improved assembly efficiency, high versatility, and high compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

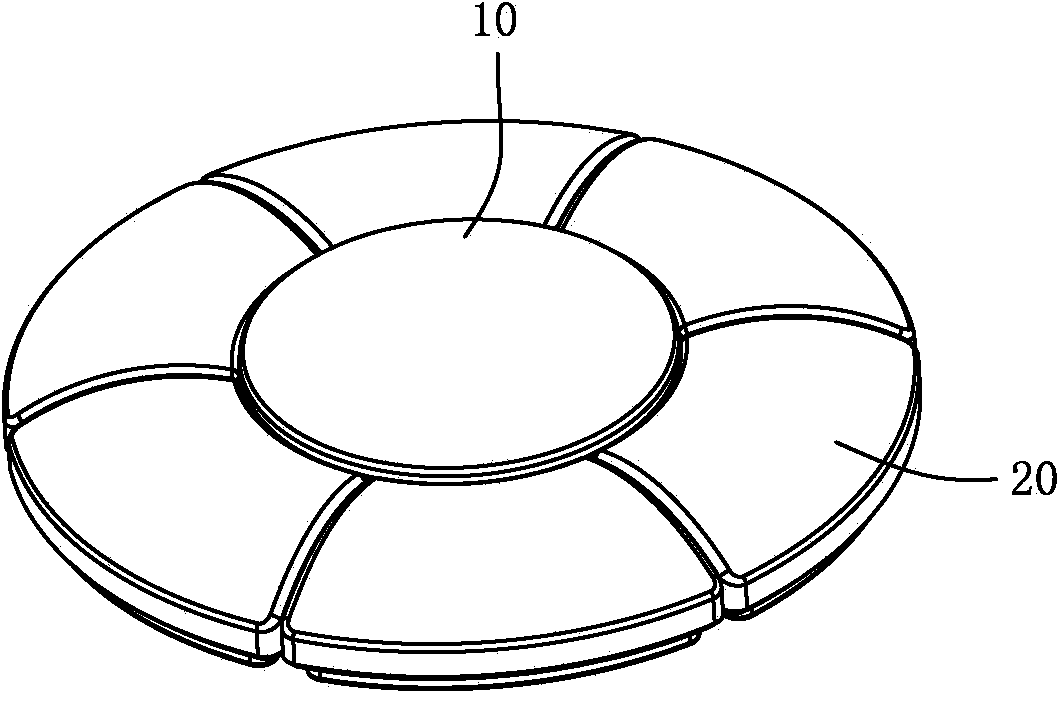

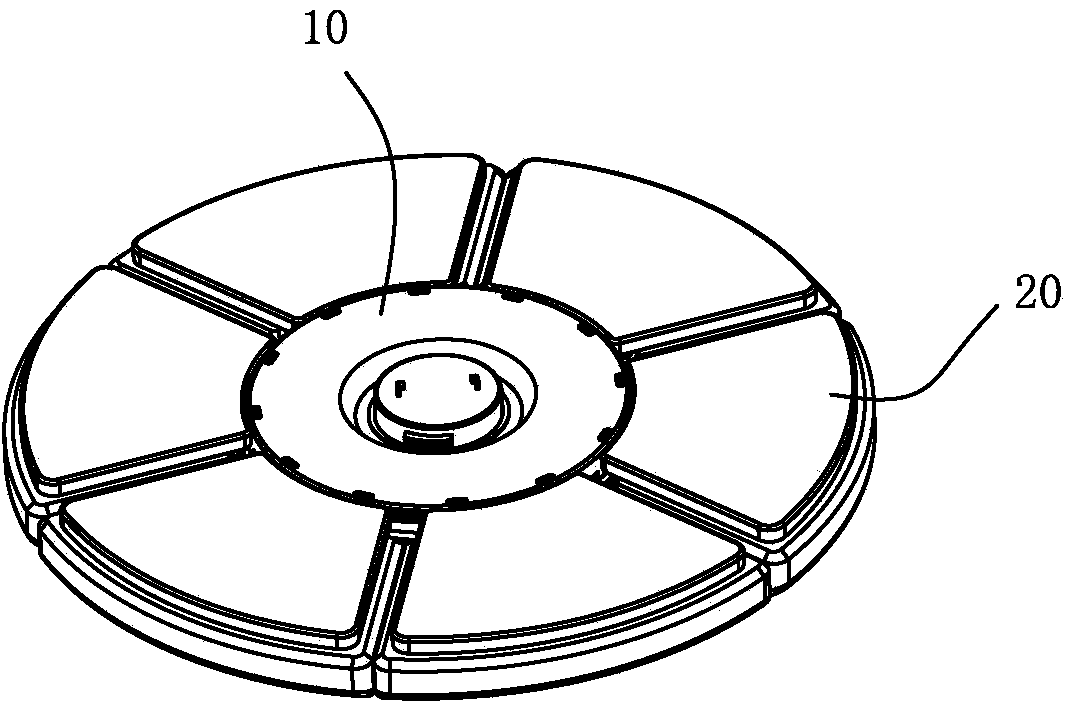

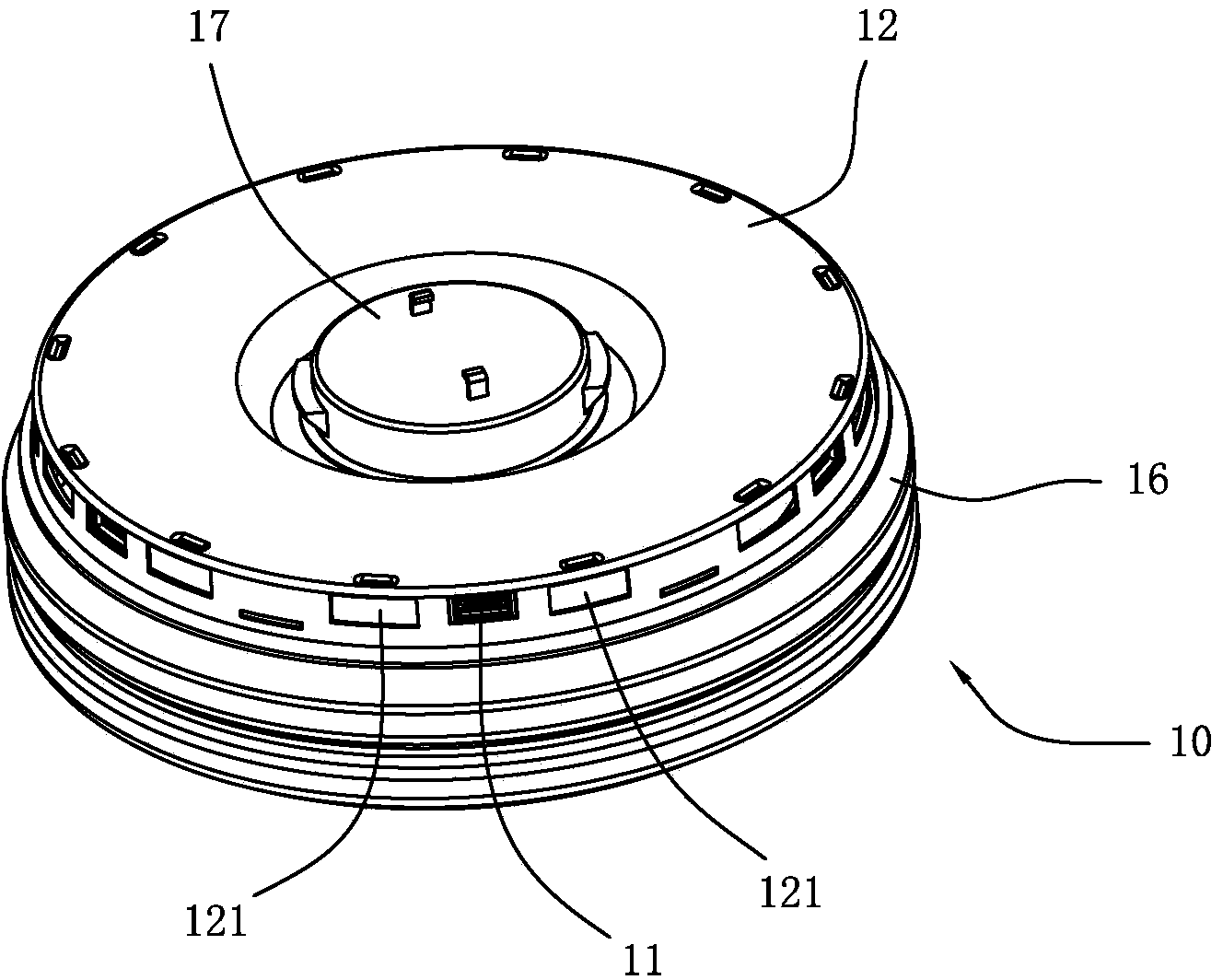

[0024] refer to Figure 1 to Figure 7 , a combined modular ceiling lamp of the present invention, comprising a central light source module 10 and a plurality of edge light source modules 20 arranged at intervals along the circumferential direction outside the central light source module 10, each of the edge light source modules 20 has a USB connector 21 The central light source module 10 is arranged at intervals along the circumferential direction with a plurality of USB interfaces 11 for inserting the USB connectors 21 .

[0025] This combined modular ceiling lamp can be used independently by setting the central light source module 10 as the basic unit ceiling lamp; meanwhile, a plurality of edge light source modules 20 are connected outside the central light source module 10 as auxiliary unit ceiling lamps, and different lamps can be used according to the selection requirements. A number of edge light source modules 20 are combined with a single central light source module 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com