A monocular vision measurement method for large parts

A measurement method and technology for large parts, applied in the field of measurement, can solve the problems of limited measurement range and inability to complete the measurement of large parts to be measured, and achieve the effect of overcoming the limitation and expanding the range of measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0030] Embodiment of a monocular vision measurement method for large parts of the present invention

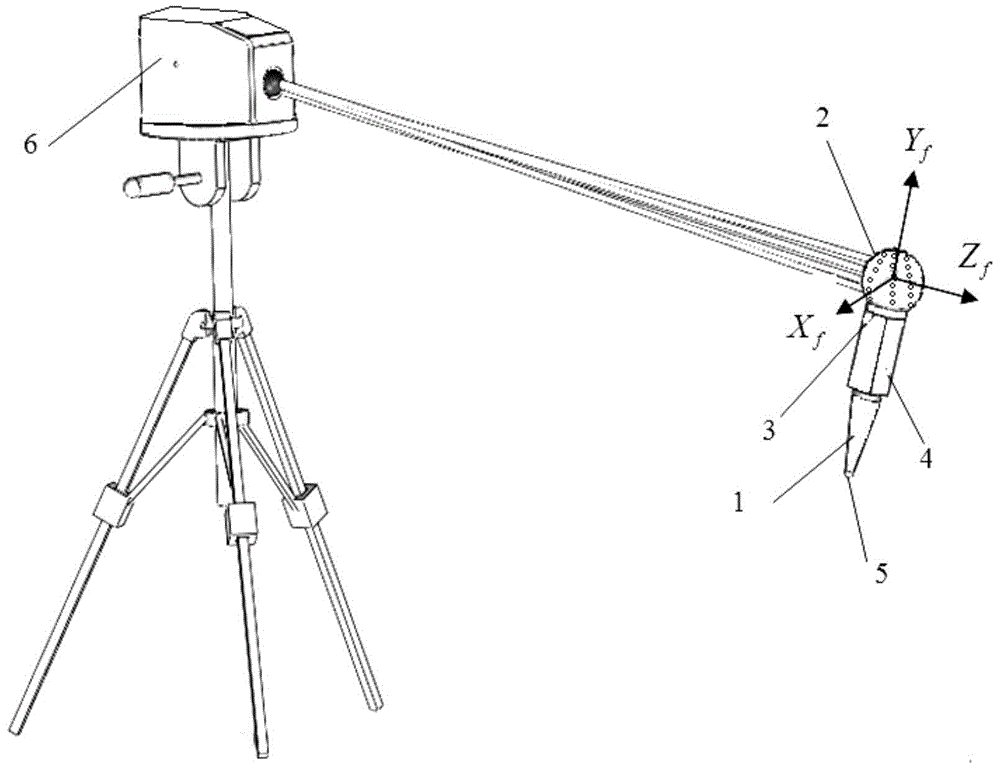

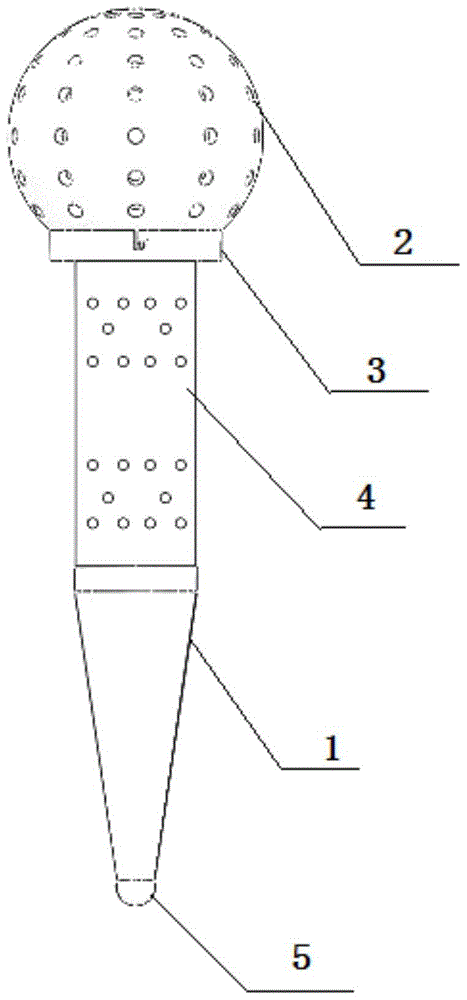

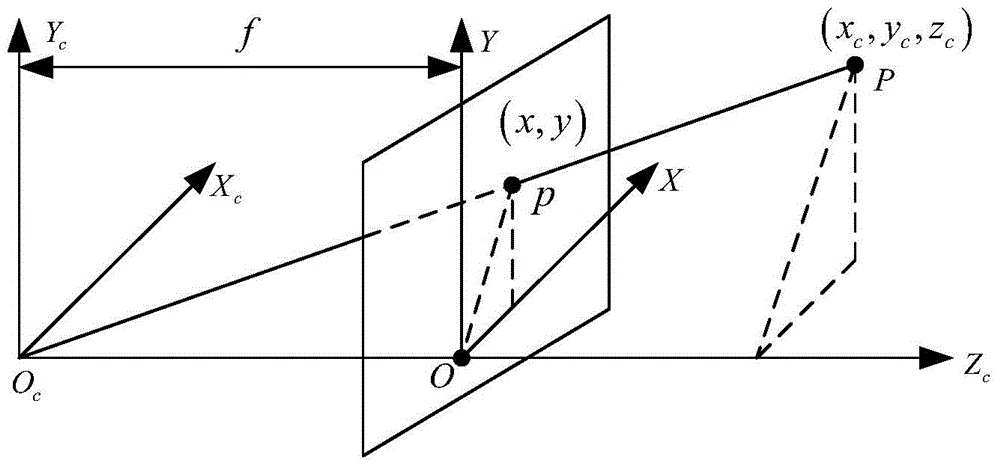

[0031] The monocular vision measurement method for large parts of the present invention accurately extracts the central coordinates of the mark points by reasonably setting the mark points, and realizes the measurement of the camera through the transfer station ball on the auxiliary target, expands the scope of measurement, and realizes the measurement of large parts. Fast, low-cost measurement requirements. The measurement system used in the present invention is as figure 1 As shown, including camera 6, computer and auxiliary measurement target, wherein the auxiliary measurement target is as figure 2 As shown, it includes the measuring rod 1, the rotating station ball 2 is installed on the measuring rod 1, the rotating station platform 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com