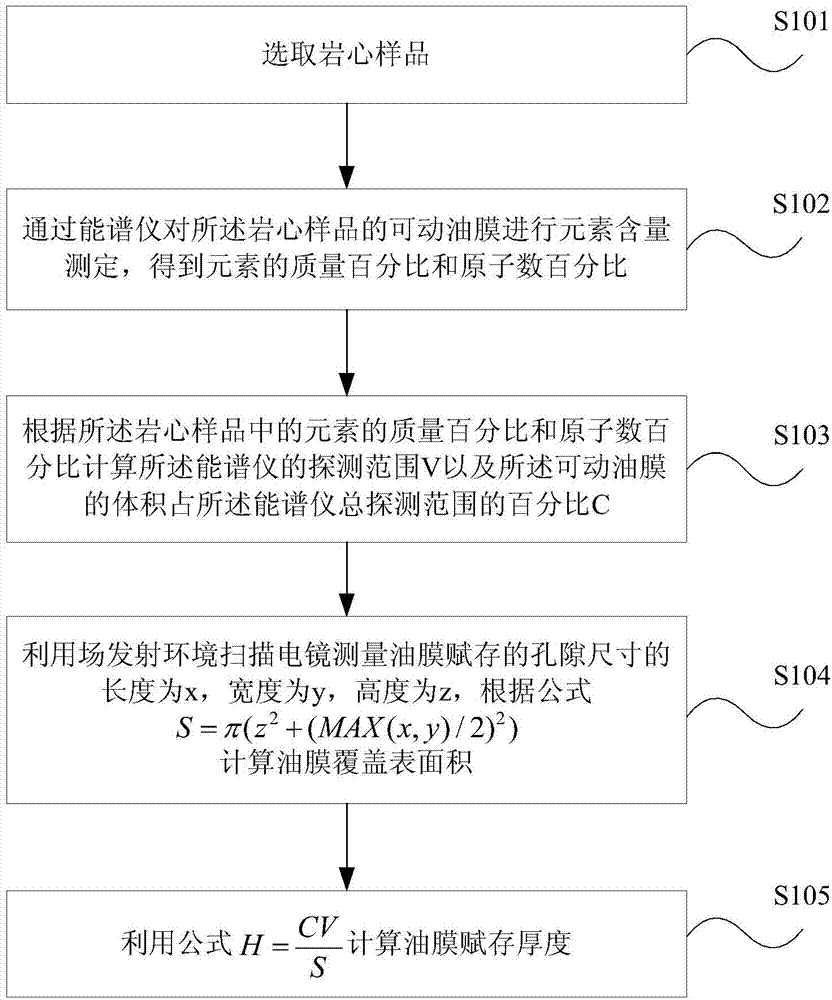

Method for measuring occurrence thickness of oil film in tight reservoir micro-nano pore throat

A technology of micro-nano pores and tight reservoirs, which is used in the measurement of the thickness of oil film in the micro-nano pore throats of tight reservoirs, and in the field of experimental calculation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

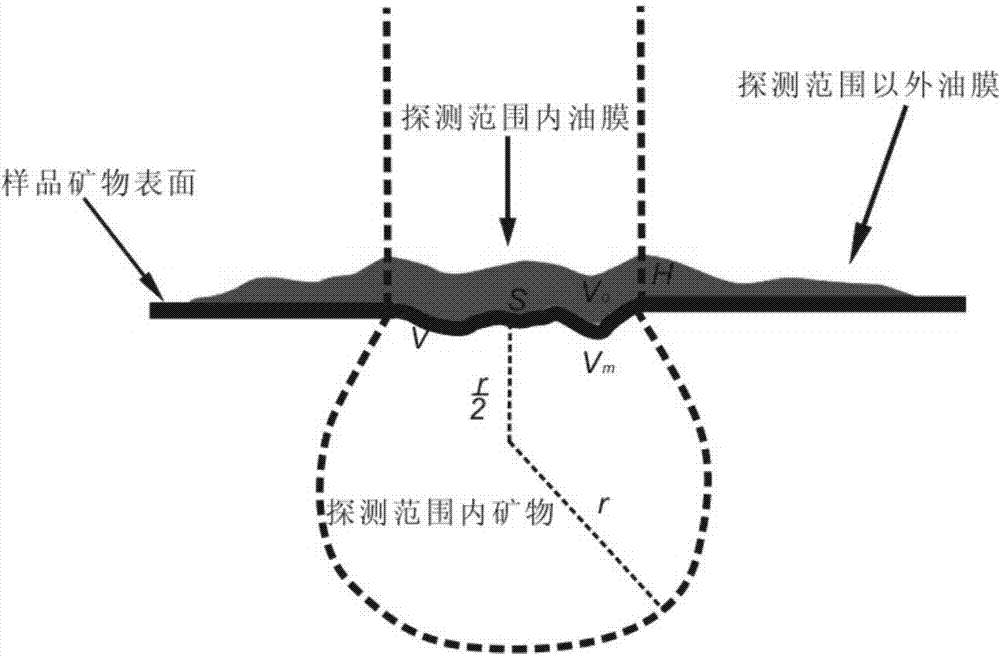

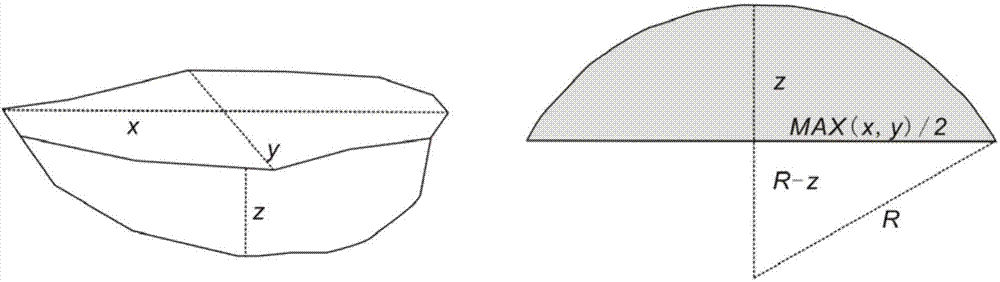

Method used

Image

Examples

specific Embodiment

[0038] Taking the No. 3 point of the 2121m sample in well R59 as an example, the main elements are C, O, and S i , the mass percentages are 71.22%, 22.55% and 5.2%, and the atomic number percentages are 78.41%, 18.64% and 2.45%, respectively, indicating that the main mineral within the detection range is quartz (S i o 2 ), S i o 2 The atomic percentage of O in S is i 2 times the atomic percentage, which is 4.9%, so S i o 2 The ratio of O atoms in the total O atoms is 0.26, then S i o 2 The atomic mass percentage of O in the oil film is 5.93%, so it can be calculated that the atomic mass percentage of O in the oil film is 16.62%. Then S i o 2 The mass percentage is 5.93%+5.2%=11.13%, the hydrocarbon mass percentage is 71.22%+16.62%=87.84%, and the corresponding hydrocarbon molecular expression can be written as C 71 o 14 h n x m , where n represents the proportion of H elements, X represents the other elements in hydrocarbon molecules other than C, O, and H, and m ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com