Backend detecting method for diodes and audions

A detection method and triode technology, applied in the direction of single semiconductor device testing, etc., can solve problems such as inability to adapt to large-scale production, irregularities and systems, etc., and achieve the effects of good test consistency, increased normal rate, and good adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

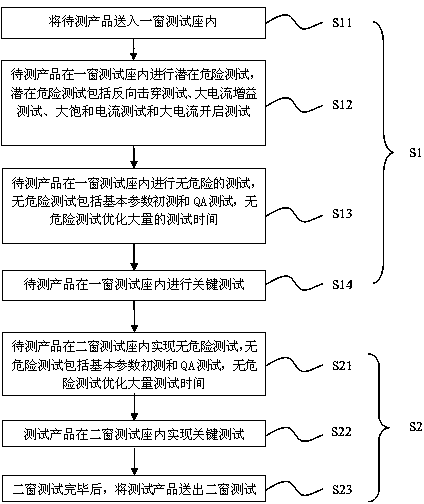

[0027] Such as figure 1 As shown, the back-end detection method of diodes and triodes is mainly used for the packaging and testing of diodes and triodes to ensure the consistency of the test process. It includes a one-window test and a two-window test, wherein the one-window test includes the following steps :

[0028] S11: Send the product to be tested into a window test socket;

[0029] S12: The product to be tested is tested for potential hazards in a window test socket. Potential hazard tests include reverse breakdown test, high current gain test, large saturation current test and high current open test;

[0030] S13: The product to be tested is subjected to a non-hazardous test in a one-window test socket. The non-hazardous test incl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com