Novel HEMT for improving piezoelectric polarization intensity

A new type of polarization strength technology, applied in the field of microelectronics, can solve the problems of insufficient detection sensitivity of pressure sensors and insufficient piezoelectric polarization strength, and achieve high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

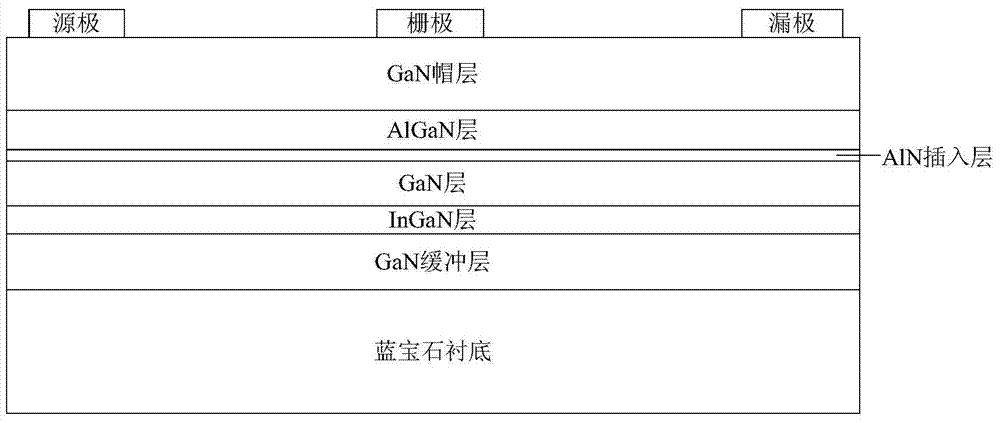

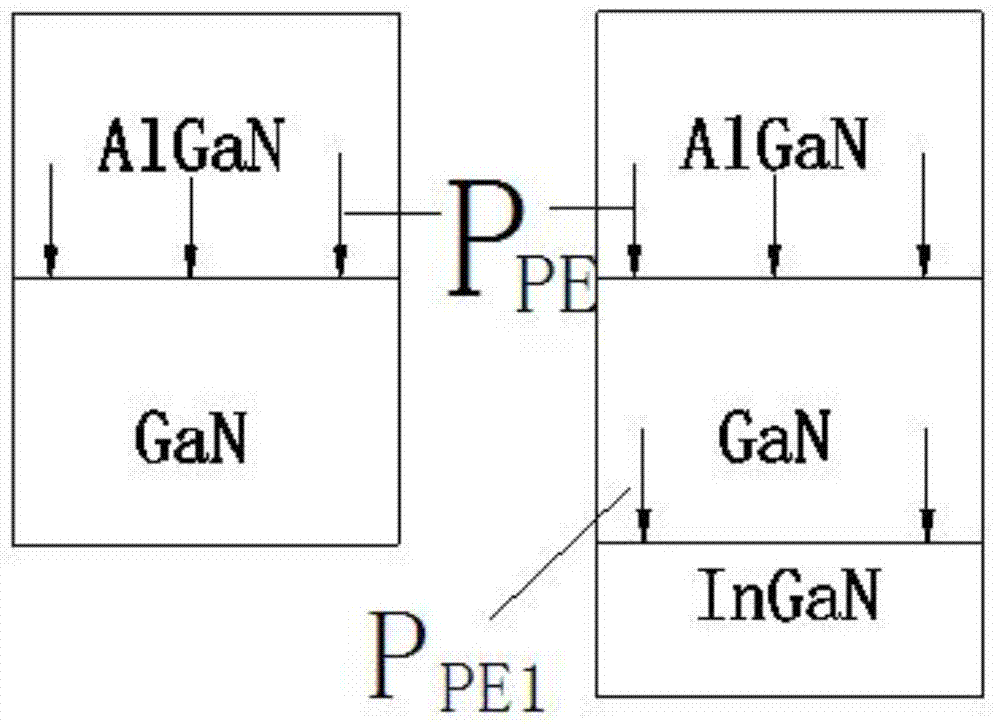

[0018] Such as figure 1 , figure 2 Shown: A novel HEMT structure with enhanced piezoelectric polarization comprising: a sapphire substrate. GaN buffer layer, InGaN layer, GaN layer, AlN insertion layer, AlGaN layer, GaN cap layer:

[0019] Based on the AlGaN / AlN / GaN structure HEMT containing the AlN spacer layer, the present invention inserts an InGaN layer under the GaN layer to form an Al x Ga 1-x N / AlN / GaN / In y Ga 1-y HEMT with N structure, the cross-section is shown in figure 1 shown. Channels are formed between AlGaN and GaN, and between GaN and InGaN, and the 2DEG generated due to the polarization effect is in the channel. The InGaN layer is inserted, and the lattice constant of GaN in the GaN / InGaN structure is smaller than that of InN, so that the GaN lattice is strained, and the piezoelectric polarization generated by the strain is stronger than that between AlGaN / GaN, so that The polarization effect of the device is stronger under the same pressure, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com