Battery cooling and heating device for electric automobile

A cooling and heating device, electric vehicle technology, applied to batteries, secondary batteries, circuits, etc., can solve the problems of poor battery temperature consistency, large cooling loss, high cost, etc., achieve excellent noise reduction design structure, and improve temperature consistency performance, the effect of small system footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention are described in detail below. Examples of the embodiments are shown in the accompanying drawings, in which the same or similar reference numerals indicate the same or similar elements or elements with the same or similar functions. The embodiments described below with reference to the accompanying drawings are exemplary, and are only used to explain the present invention, and cannot be construed as limiting the present invention.

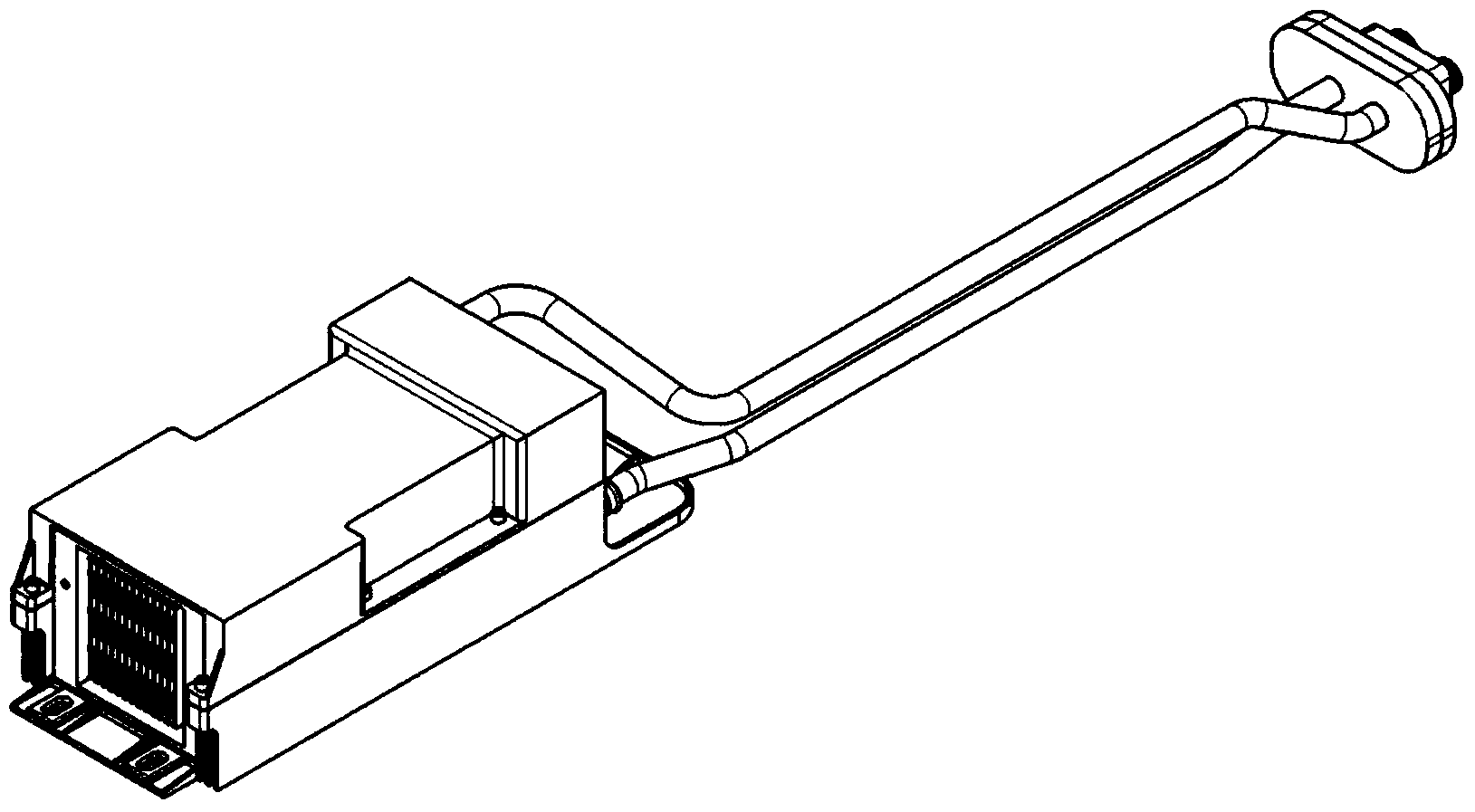

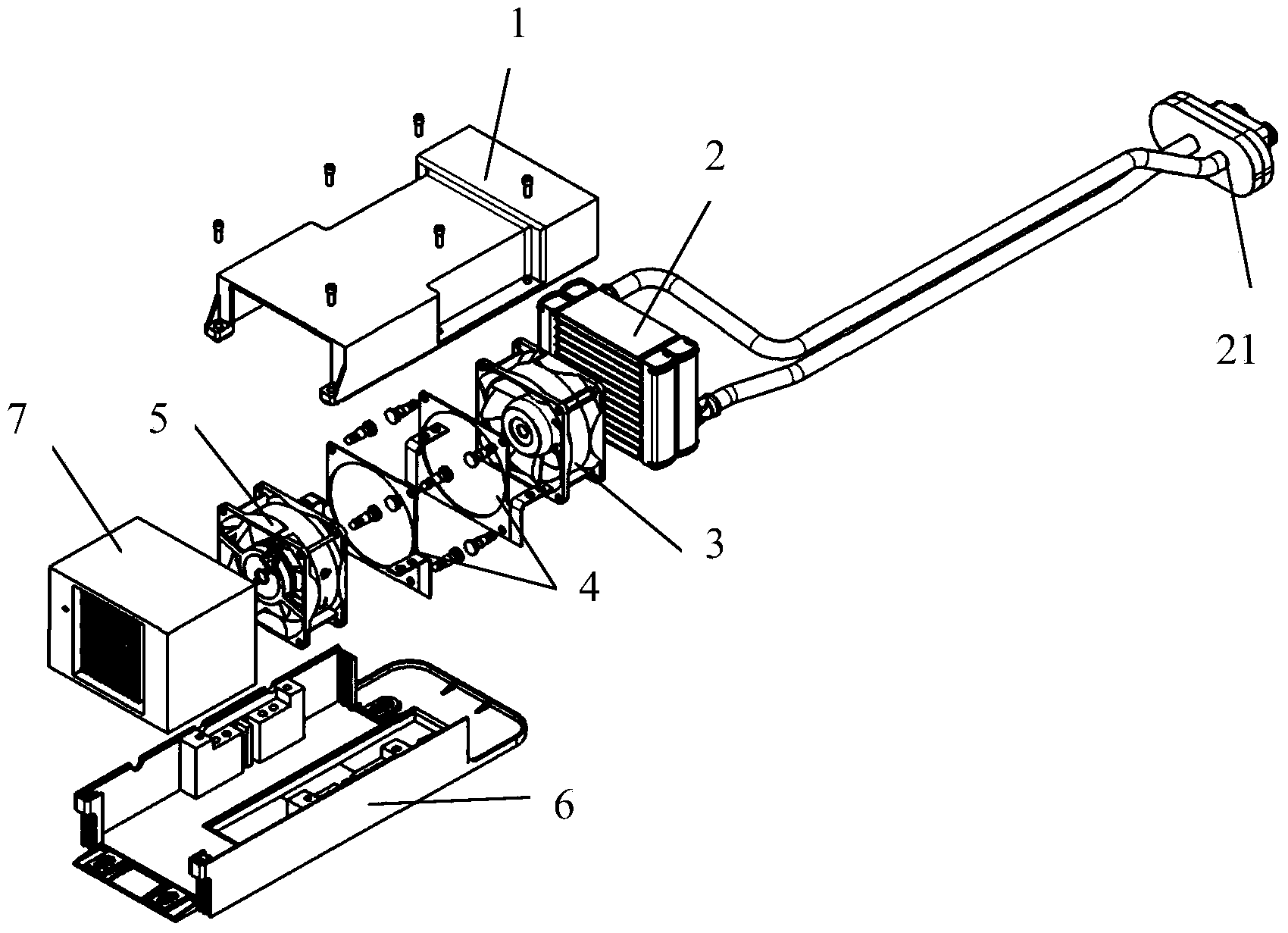

[0026] reference figure 1 with figure 2 As shown, the battery cooling and heating device is composed of 7 parts: an upper casing 1, an evaporator 2, a fan A3, a fan bracket 4, a fan B5, a lower casing 6 and a heater 7.

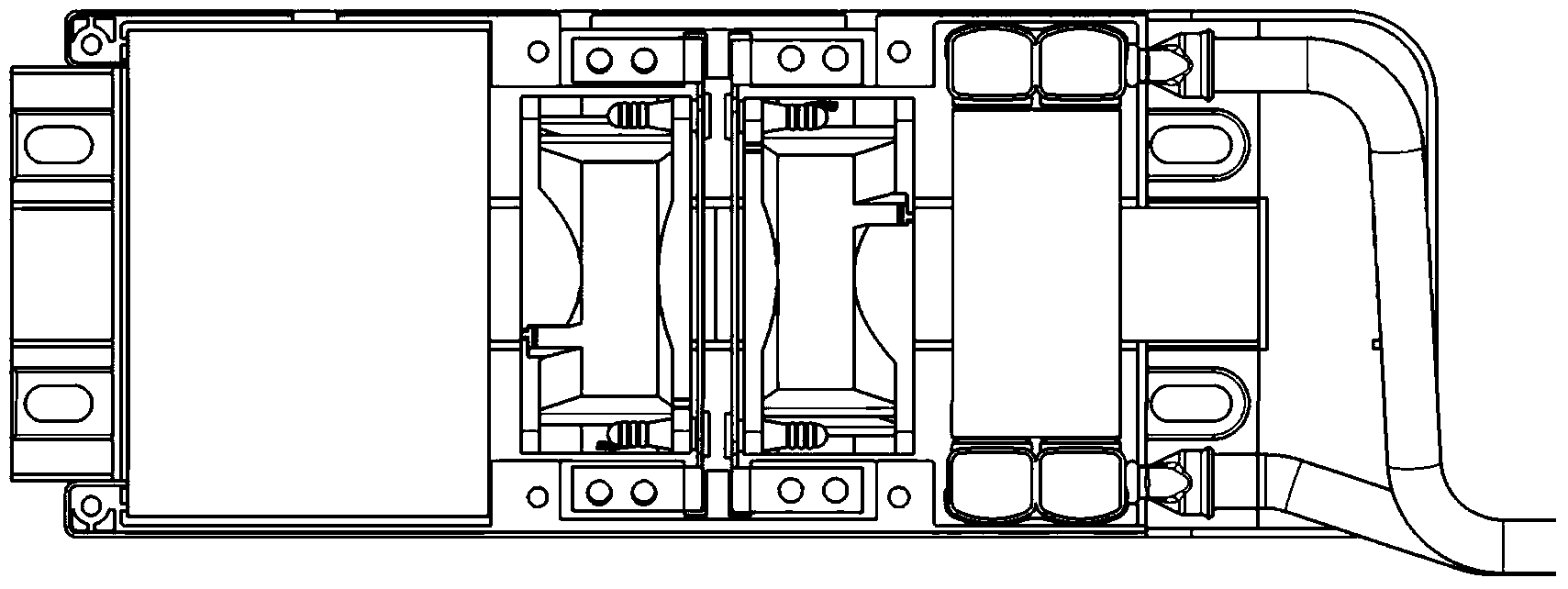

[0027] figure 2 The structure of the evaporator assembly shown is composed of header pipes, flat tubes, fins, refrigerant pipes and flange fixing structure. The evaporator assembly is arranged inside the upper shell 1 and the lower shell 6, and is fixed in the form of size limit ; The fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com