Multi-color semiconductor laser beam combining device

A semiconductor and laser technology, applied in the field of multi-color semiconductor laser beam combining devices, can solve the problems of non-guarantee, channel interference, high yield, etc., and achieve the effect of ensuring polarization performance, easy assembly and adjustment, and stable performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

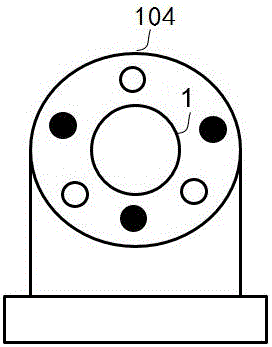

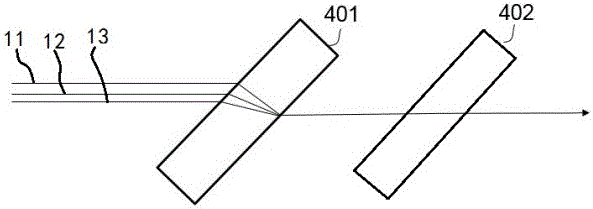

[0025] A kind of multi-color semiconductor laser beam combiner of the present embodiment, such as figure 1 As shown, it includes a first semiconductor laser 101, a second semiconductor laser 102 and a third semiconductor laser 103 with different wavelengths connected in parallel; corresponding to the first semiconductor laser 101, the second semiconductor laser 102 and the third semiconductor laser 103 respectively The first beam polarization improving device 21, the second beam polarization improving device 22 and the third beam polarization improving device 23 connected in parallel prevent the feedback of the same polarization part of the beam to reduce the increase of the resulting beam noise, and the beam The polarization improving devices 2 are respectively located on the output optical paths of the corresponding semiconductor lasers 1 . The beam combining mirror group 3 for beam combining, the input end of the beam combining mirror group 3 is located on the output optica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com