Aromatic polyester-based resin foam particles for in-mold foam molding, method for producing same, in-mold foam molded body, composite structural member, and member for automobile

A technology for aromatic polyester and foam moldings, which is applied to synthetic resin layered products, chemical instruments and methods, transportation and packaging, and can solve the problem of storage time (short molding life, insufficient foaming Eliminate miscellaneous problems, and achieve the effect of excellent mechanical strength and appearance, and long molding life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

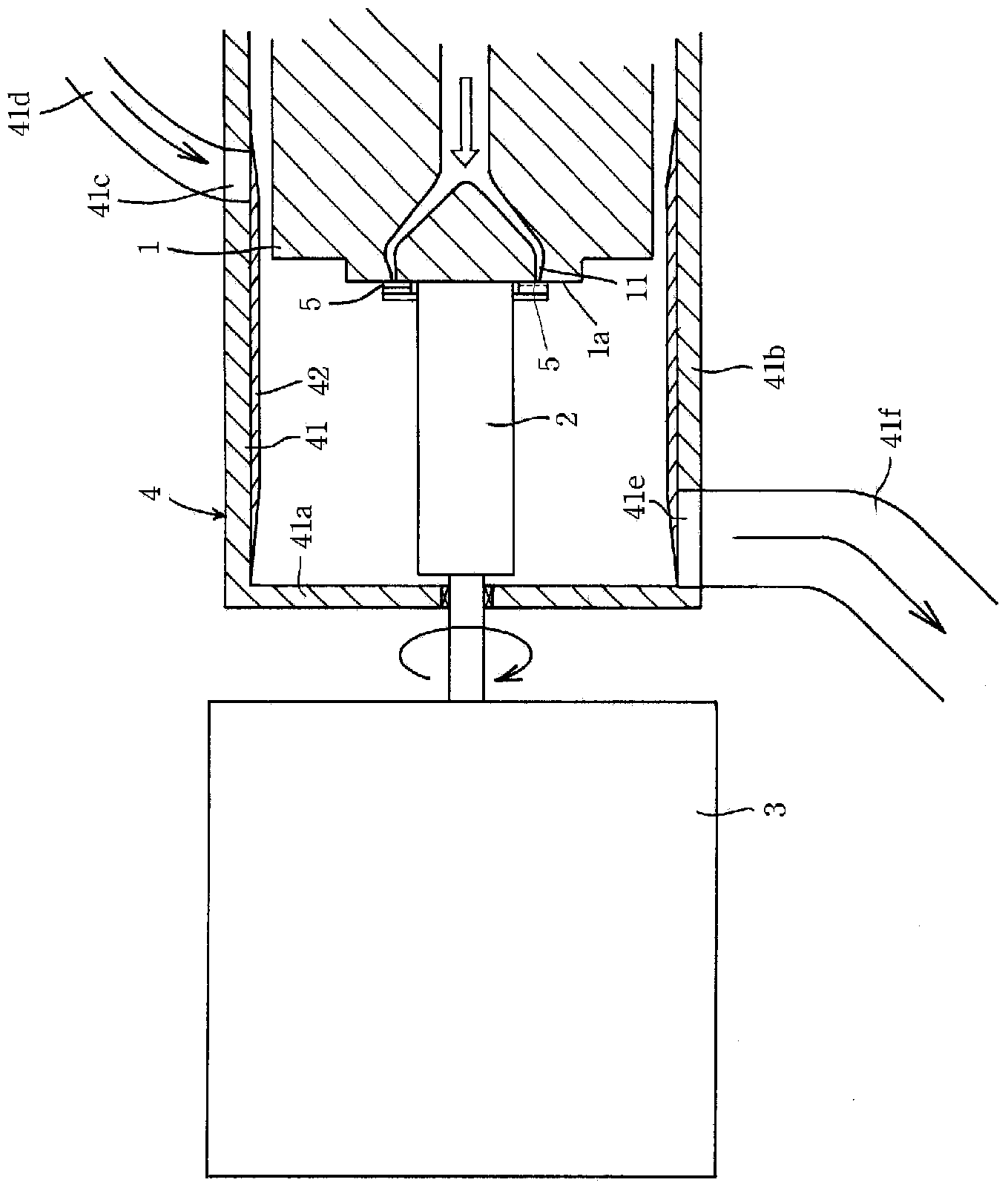

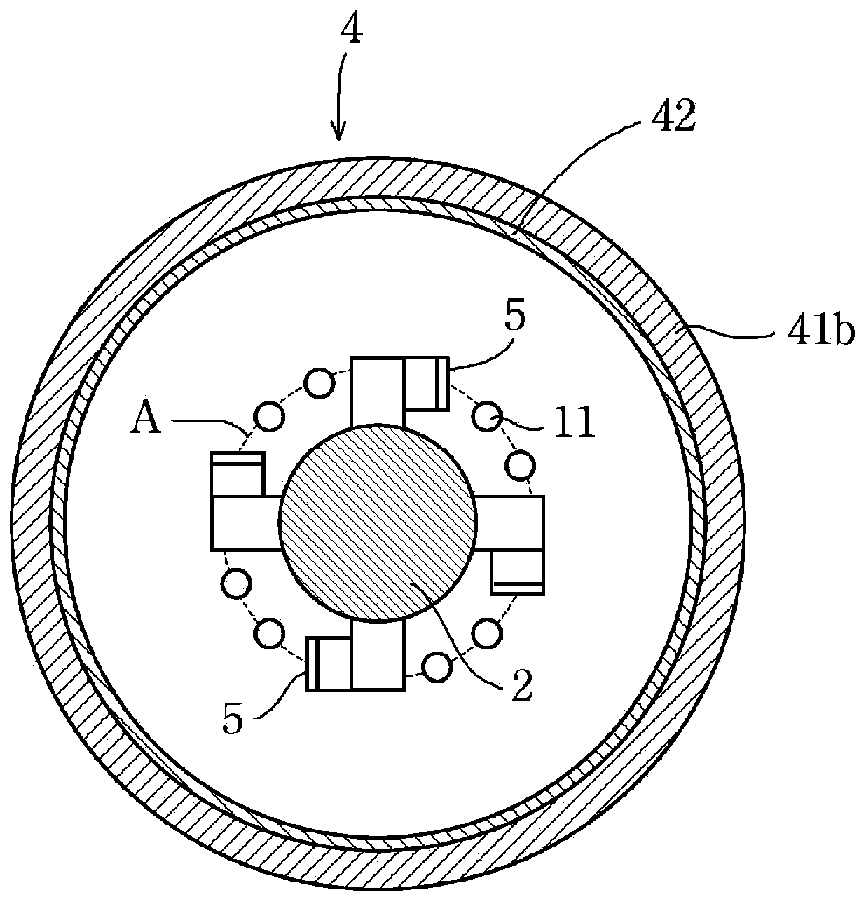

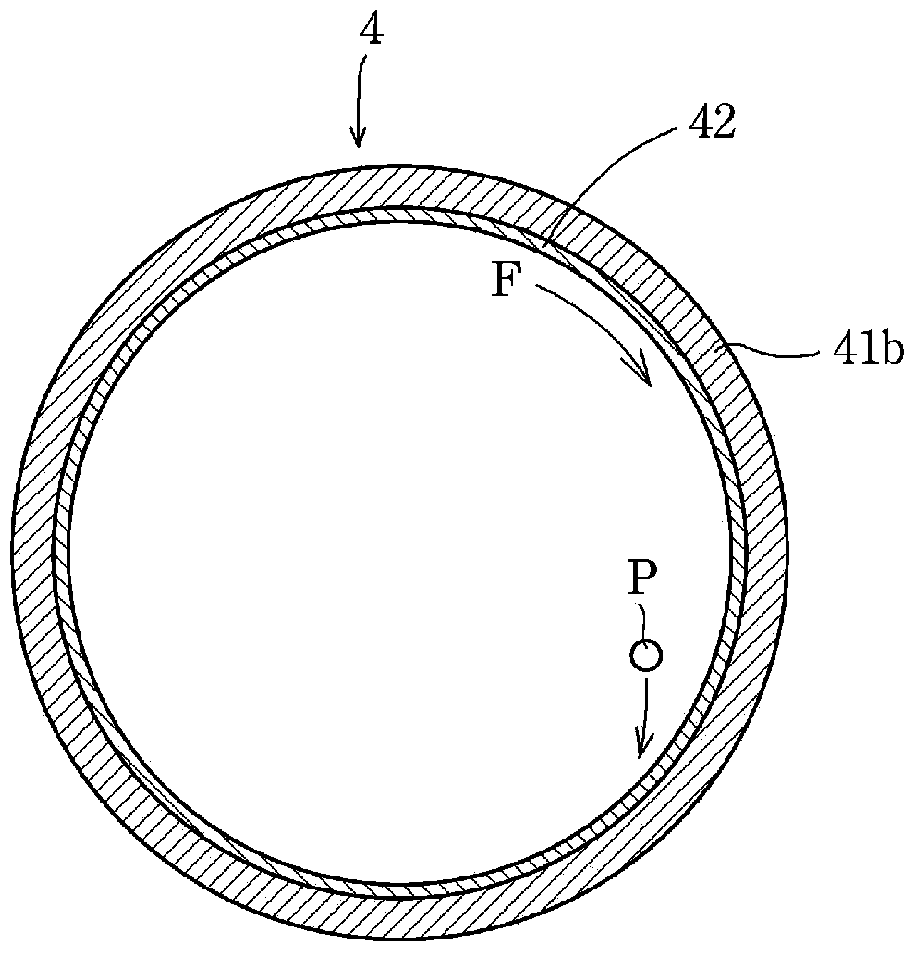

[0167] used figure 1 and figure 2 Fabrication setup shown. First, a single-screw extruder with a diameter of 65 mm and an L / D ratio of 35 supplied polyethylene terephthalate (trade name "SA-135" manufactured by Mitsui Chemicals Co., Ltd., melting point: 247.1°C, properties Viscosity: 0.88) 100 parts by weight, masterbatch containing talc in polyethylene terephthalate (polyethylene terephthalate content: 60% by weight, talc content: 40% by weight, polyethylene terephthalate content: 40% by weight, polyethylene terephthalate Intrinsic viscosity of ethylene terephthalate: 0.88) A polyethylene terephthalate composition comprising 1.8 parts by weight and 0.20 parts by weight of pyromellitic anhydride was melt-kneaded at 290°C.

[0168] Next, butane composed of 35% by weight of isobutane and 65% by weight of n-butane was pressed into the molten state at 0.7 parts by weight relative to 100 parts by weight of polyethylene terephthalate from the middle of the extruder. In the poly...

Embodiment 2)

[0179] On the way from the extruder, butane composed of 35% by weight of isobutane and 65% by weight of n-butane was injected into the polyethylene terephthalate in a molten state at 0.3 parts by weight relative to 100 parts by weight of polyethylene terephthalate. In the polyethylene terephthalate composition, it was uniformly dispersed in polyethylene terephthalate, except that, the same operation as in Example 1 was carried out to obtain polyethylene terephthalate for in-mold foam molding. Ethylene glycol diformate foamed particles.

Embodiment 3)

[0181] On the way from the extruder, butane composed of 35% by weight of isobutane and 65% by weight of n-butane was injected into the polyethylene terephthalate in a molten state at 0.65 parts by weight relative to 100 parts by weight of polyethylene terephthalate. In the polyethylene terephthalate composition, it was uniformly dispersed in polyethylene terephthalate, except that, the same operation as in Example 1 was carried out to obtain polyethylene terephthalate for in-mold foam molding. Ethylene glycol diformate foamed particles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com