Fish fodder spraying and classifying device

A grading device, fish feed technology, applied in the directions of injection device, feed, solid separation, etc., can solve the problems of increasing equipment manufacturing costs, processing procedures, and increasing processing costs, saving machinery manufacturing costs and processing costs, and saving spraying grease. , the effect of spraying thoroughly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the examples and accompanying drawings, because the following description is only the specific implementation of the present invention, but the protection of the present invention is not limited thereto, and any changes or substitutions conceived by those skilled in the art are all covered within the protection scope of the present invention.

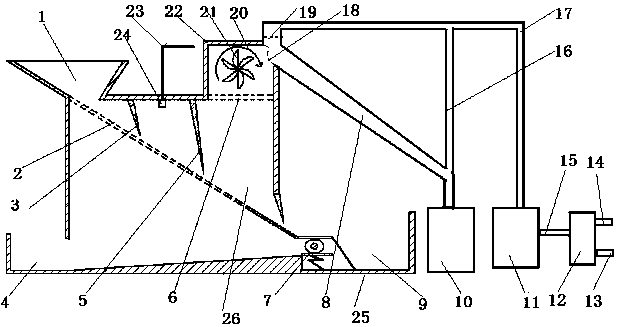

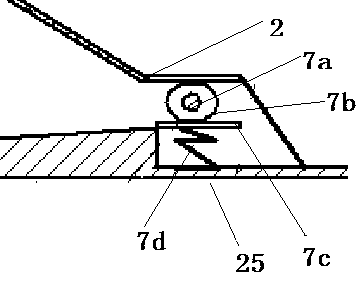

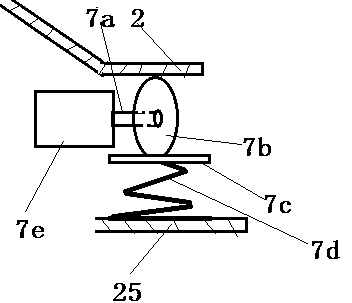

[0021] A fish feed spraying and grading device, the device includes a feeding port (1), a grading sieve (2), a crushed material recovery bin (4), a vibrating device (7), a dust feed recovery pipe (8), and an oil gas recovery pipe ( 17), qualified feed bin (9), dust feed recovery box (10), oil-gas cooling box (11), oil-water separation box (12), high-temperature grease nozzle (24), fan (21), feed grading and spraying bin ( 26); the grading sieve (2) is set under the feeding port (1), and the grading sieve (2) is connected with the vibrating device (7); the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com