A method for making building sand from tailings sand

A technology for construction and tailings sand, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of tailings pond safety hazards, backward technology, secondary pollution, etc., and solve environmental pollution and safety hazards , Promote tax revenue, and promote the effect of economic development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

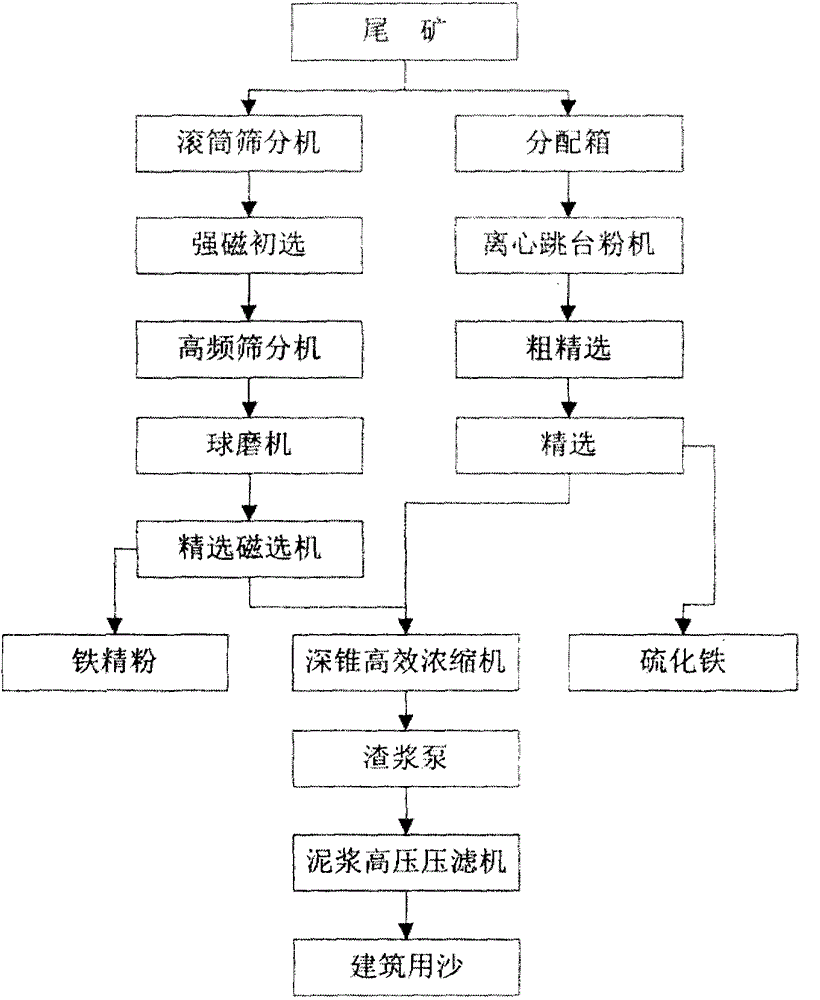

[0015] Such as figure 1 Shown is the process flow chart of tailings sand making construction sand in the embodiment of the present invention, and its specific steps are:

[0016] (1) Recover the magnetic iron in the discarded tailings sand, first use a strong magnetic field for primary selection and enrichment, then ball mill grinding and selection, and iron fine powder, that is, iron removal.

[0017] (2) The tailings are pumped to the distribution box for distribution to the gravity separation equipment for desulfurization: coarse, medium and selected three steps to select sulfur concentrate, that is, desulfurization.

[0018] (3) The tailings are discharged to the gravity cyclone by the slurry pump for mud separation. The tailings and mud are separated, and the mud is discharged upstream to the mud storage through the gravity cyclone, that is, desliming.

[0019] (4) The tailings are discharged to the dewatering screen through the down stream for dehydration, and the dehyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com