Segment matching and prefabricating method for large-scale standardized structural element

A segment and component technology, applied in the field of segment matching prefabrication of large-scale standard components, can solve problems such as large randomness, increased difficulty, and inability to guarantee the linear relationship of longer segments, so as to achieve the effect of ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

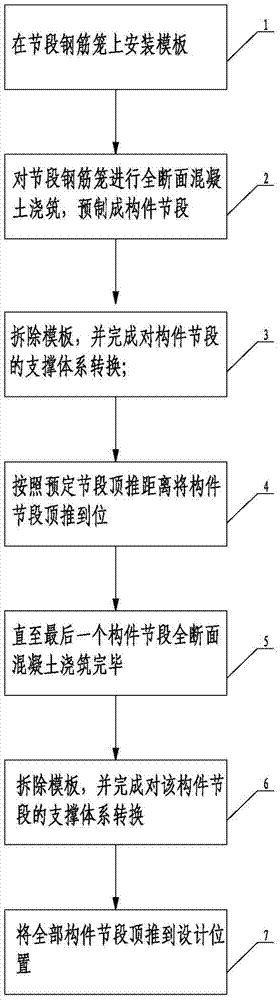

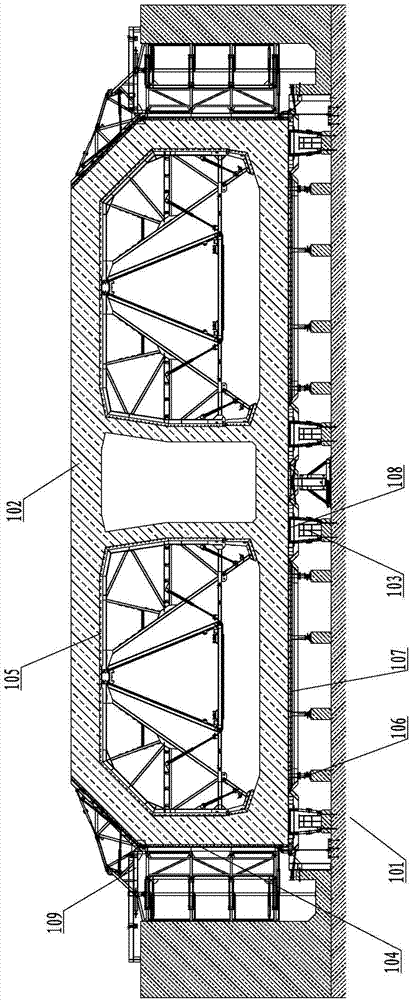

[0040] see figure 1 , figure 2 Shown, the section matching prefabrication method of a kind of large-scale standard component of the present invention, the method may further comprise the steps:

[0041] 1. Install the bound segmental reinforcement cage 102 on the pouring pedestal 101; and install a formwork on the segmental reinforcement cage.

[0042] 2. Carry out full-section concrete pouring on the segmental reinforcement cage, and prefabricate the component segment; the full-section concrete pouring means that from the cross-sectional view of the component segment, no construction joints are set in the middle, but Continuous pouring is completed at one time.

[0043] 3. Remove the formwork on the component segment, install a sliding support device at the bottom of the component segment, and complete the alignment of the component through the sliding support device (not shown in the figure) and the slide rail 103 correspondingly arranged at the lower end of the sliding s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com