Preparation method and application of pyrolysis-carboxymethylated starchy humectant for cigarettes

A humectant for cigarettes and carboxymethylation technology, which is applied in the field of preparation of pyrolysis-carboxymethylated starchy humectant for cigarettes, can solve the problems of complex preparation process, few sources of raw materials, and high cost, and achieve Wide range of sources, reduced consumption of tobacco leaves, and improved processing resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

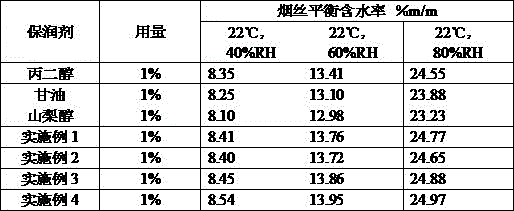

Examples

Embodiment 1

[0019] Example 1. Weigh 350g of wheat starch, add 4g of concentrated sulfuric acid dropwise, stir and mix evenly, put it into a self-made dry reactor, react at 130°C for 5 hours, and neutralize it with 10% sodium hydroxide ethanol aqueous solution after cooling , and then dried, crushed and sieved to obtain pyrolytic dextrin. Add pyrolytic dextrin to ethanol / water (V / V=60:40) solution to make 37% starch milk, then add 20g sodium hydroxide and 40g sodium chloroacetate in sequence, and react at 45°C for 5 hours , neutralized to neutral with concentrated hydrochloric acid, and then dehydrated, washed, dried, crushed and sieved in sequence to obtain pyrolysis-carboxymethylated starch. Dissolving the pyrolyzed-carboxymethylated starch in water to form a 40% aqueous solution, adding 0.2% preservative and 0.2% defoamer to obtain the starchy humectant for cigarettes.

Embodiment 2

[0020] Example 2. Weigh 350g of potato starch, add 9g of concentrated sulfuric acid dropwise, stir and mix evenly, put it into a self-made dry reactor, react at 140°C for 7 hours, and neutralize it with 10% sodium hydroxide ethanol aqueous solution after cooling , and then dried, crushed and sieved to obtain pyrolytic dextrin. Add pyrolytic dextrin to ethanol / water (V / V=60:40) solution to make 37% starch milk, then add 50g sodium hydroxide and 80g sodium chloroacetate in sequence, and react at 45°C for 5 hours , neutralized to neutral with concentrated hydrochloric acid, and then dehydrated, washed, dried, crushed and sieved in sequence to obtain pyrolysis-carboxymethylated starch. Dissolving the pyrolyzed-carboxymethylated starch in water to form a 40% aqueous solution, adding 0.2% preservative and 0.2% defoamer to obtain the starchy humectant for cigarettes.

Embodiment 3

[0021] Example 3. Weigh 350g of wheat starch, add 15g of concentrated phosphoric acid dropwise, stir and mix evenly, put it into a self-made dry reactor, react at 150°C for 10 hours, and neutralize it with 10% sodium hydroxide ethanol aqueous solution after cooling , and then dried, crushed and sieved to obtain pyrolytic dextrin. Add 300g of pyrolytic dextrin into ethanol / water (V / V=70:30) solution to make 37% starch milk, then add 80g of sodium hydroxide and 150g of sodium chloroacetate in turn, and react at 45°C After 5 hours, it was neutralized to neutral with concentrated hydrochloric acid, and then dehydrated, washed, dried, crushed and sieved in sequence to obtain pyrolysis-carboxymethylated starch. Dissolving the pyrolyzed-carboxymethylated starch in water to form a 40% aqueous solution, adding 0.2% preservative and 0.2% defoamer to obtain the starchy humectant for cigarettes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com